Wallbox production ramping up at Kontron: How the TS2plus transfer system from Bosch Rexroth is revolutionising e-mobility manufacturing. With a 50-second cycle time, FMT Flexible Montagetechnik demonstrates how modern transfer technology is driving electric mobility forward.

The growing demand for charging infrastructure for electric mobility presented Kontron, an electronics manufacturer with expertise in plastics based in Leipzig, with new challenges. The aim was to develop an assembly line capable of producing wall boxes in a wide variety of designs and in large quantities. The target was an output of one wall box every 50 seconds. In order to keep up with international competition and establish this production in Saxony, the focus was on efficiency through a high degree of automation while complying with automotive standards. This also required the seamless integration of the assembly line into the plant's existing Manufacturing Execution System (MES).

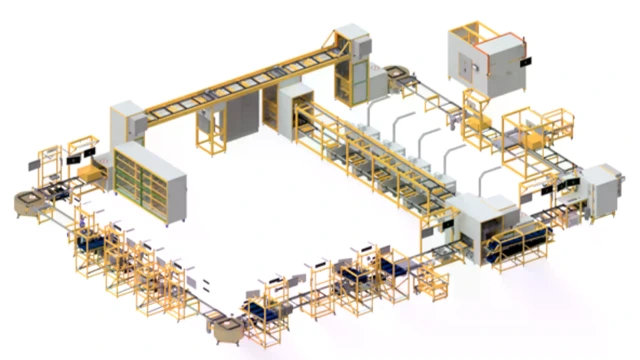

The system uses the TS2plus transfer system in a two-stage design with vertical connection via lifts. The workpiece carriers (640 × 640 mm) are universally applicable and equipped with modular holders, enabling flexible product processing.

The overall system at a glance clearly shows its dimensions: the arrangement of the various workstations, the consolidation of material flows and the integration into the existing factory MES demonstrate the high level of expertise of the FMT design team (image source: FMT).

• Area: 34 × 18 m

• Cycle time: approx. 50 seconds

• Operation: three-shift system, 5 days/week, 50 weeks/year

• 11 assembly workstations (HAPs) + laser cells, testing stations and packaging unit

The line combines manual, semi-automated and fully automated stations. Assembly takes place step by step at manual workstations, followed by high-voltage and end-of-line testing. After successful testing, the type plate is applied by laser and the product is transferred to packaging. NIO products are automatically ejected for reworking.

The system is fully integrated into the existing factory MES. All relevant parameters – from assembly and testing to labelling – are controlled, monitored and documented in real time. This enables complete traceability and supports quality assurance in accordance with DIN EN ISO 9001:2015.

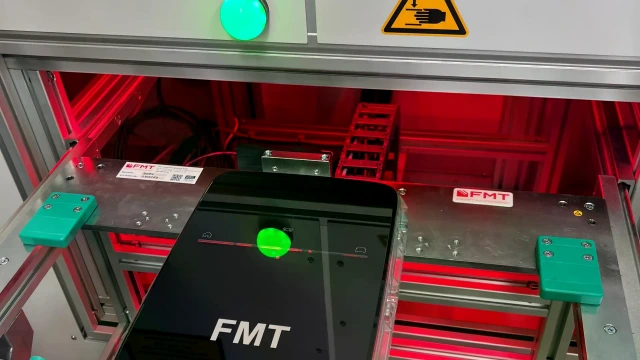

Preparation area for a laser cell (image source: FMT).

The packaging line comprises three packing stations with manual roller conveyors, storage areas for cardboard blanks and accessories, and a height-adjustable loading station for pallets – all integrated into the overall process.

The success of the project was largely based on the professional implementation by FMT on site – as a general contractor with comprehensive responsibility. As a Certified Excellence Partner of Bosch Rexroth, the Chemnitz-based automation experts combine proven Rexroth technology with regional engineering expertise.

Direct communication channels, in-depth engineering expertise and personal support from the concept phase to series production ensure trust and maximum planning reliability.

Author: Michael Enger

Position: Geschäftsführer der FMT Flexible Montagetechnik

Phone: +49 3722 77780

Michael Enger

Already connected on LinkedIn?

Michael Enger

Bosch Rexroth AG