As part of an upgrade to the end of line packaging machinery for one of their high-capacity stick ice block lines, Pixie Ice cream required a new conveying solutions for two sections of the upgrade.

One section, Section 1, required a conveying system to transfer the individually wrapped products to the entry of the new robotic packaging machinery. It was required to have a small footprint while also presenting the individual products in the correct orientation for the packaging machine to sort them correctly into cartons or trays. Additionally, in the instance of a spillage, this conveyor solution needed the ability to be washed down.

The other section, Section 2, required a transportation solution for the finished cartons to be moved from the packaging machine to the check, weighing and metal detection machine. As the existing robotic packaging machine had a counter-flow system, the finished product was discharged at the same end the product originally entered, creating a unique challenge within their production line.

After working together to highlight Pixie Ice-creams production challenges, budget requirements and available manufacturing space to build in, Bosch Rexroth Australia came up with a solution that ticked all the boxes.

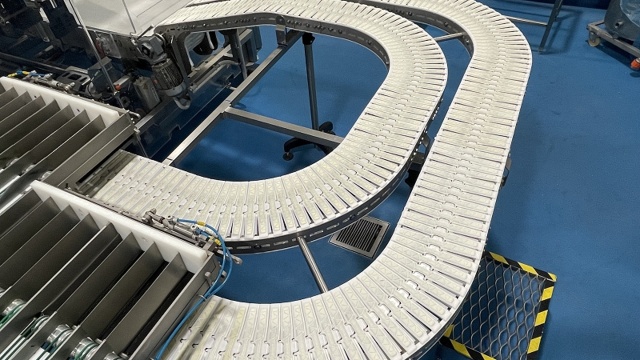

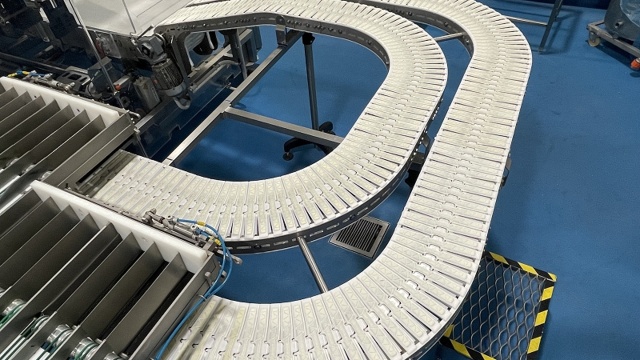

For Section 1, two VarioFlow STS Stainless Steel Conveyors which were 240mm wide were installed in a dual horseshoe configuration.

"The stainless-steel construction is flexible and easy to work with, there were minor changes to the final placement of the conveyor within the production area after the installation of the machinery and this flexibility allowed us to make the necessary changes on site in our workshop without having to wait for the supplier to remake and ship parts. " explains Murray Weller, Chief Engineer at Pixie Ice Cream.

For Section 2, a VarioFlow Plus aluminium system with two alpine conveyors were installed. One conveyor to elevate the product another to lower it. This allowed for easy access to the robotic packaging machinery in the instance of changeovers and maintenance. The low friction design also allows for longer length of conveyor belts being driven with one smaller gearbox drive unit.

To Pixie Ice-creams benefit as well, the wide range of chain sizes available in the VarioFlow plus range, meant the one conveyor belt width covered all of Pixie Ice Creams product range. These varied from 160mm up to 400mm.

In the end, we were thrilled to be able to assist Pixie Ice-cream continue on their legacy with the stick ice-block production here in Australia.