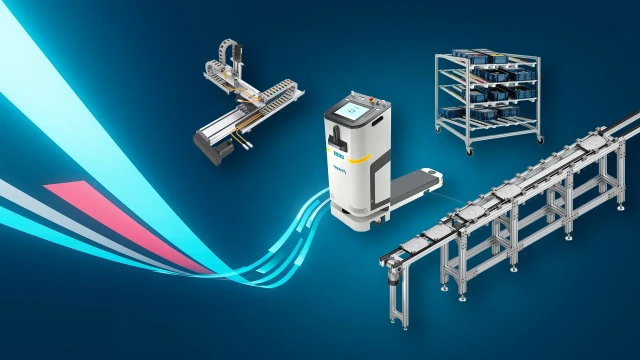

Smart solutions throughout: Automation as an enabler for the industrial transformation.

Consumer goods industry on the rise

The consumer goods and packaging industry which is regarded as relatively crisis-proof is undergoing rapid change. Considerable competitive pressure requires methods to increase productivity – while maintaining high quality standards. At the same time, flexibility and individuality are becoming increasingly important. Adaptability must be able to withstand the pace of change in the market. On top of this, factors such as the lack of personnel, high energy costs and long delivery times for components must be taken into account. Equally forward-looking and relevant is the need for sustainable production, which aims to conserve resources and reduce the CO₂ footprint.

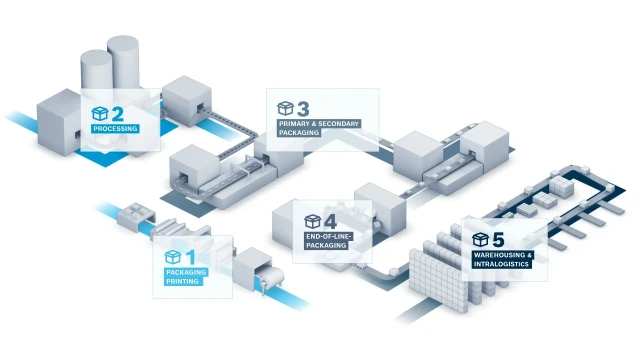

These challenges can only be met with new, integrated machine, production and packaging concepts – all driven by automation. Increasing the level of automation through the entire value stream is the key here.

Your partner in the entire value stream of the consumer goods industry

Contact us now

We know not only our technologies but also the market inside out. As a result, we can find the right solution for your factory of the future in next to no time.