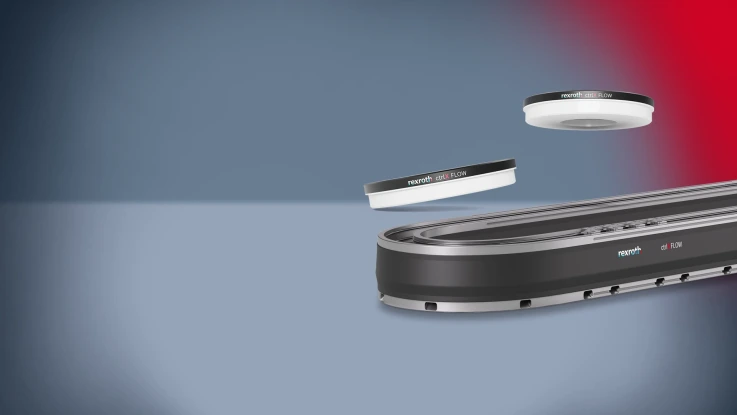

The linear motion system works according to the modular principle and is designed for modular configuration. It can be used in both in-machine and cross-machine applications. A typical use case is the direct feeding of products into a production line, eliminating the need for complex robots to remove and place components. It is also easy to combine power ovals in the machine with conventional conveyor systems, for example, to perform tasks such as forming product stacks. These applications require high performance, speed, and precision. ctrlX FLOWHS supports all these factors.

By using the linear motion system, the machine's internal transport processes between the workstations can also be easily expanded to include additional applications, for example in filling lines. To do this, bottles are gripped between two movers, transported to one filling station, labeled in another, checked in the third and bundled with other bottles in the last. Changing the bottle size in this line only requires software adjustment of the distance.

ctrlX FLOWHS is therefore perfect for use in a wide range of industries, such as consumer goods, electronics, battery or pharmaceuticals.