The expanded eLION portfolio enables the consistent electrification of the entire machine fleet. The new elements: eLION Power and Motion Control, highly compact HV motors, and a 96-volt offering for smaller off-highway vehicles.

The advancing electrification of mobile working machines brings the topics of standardization and scalability into focus. How can off-highway manufacturers increase efficiency in development and operation across all machine classes?

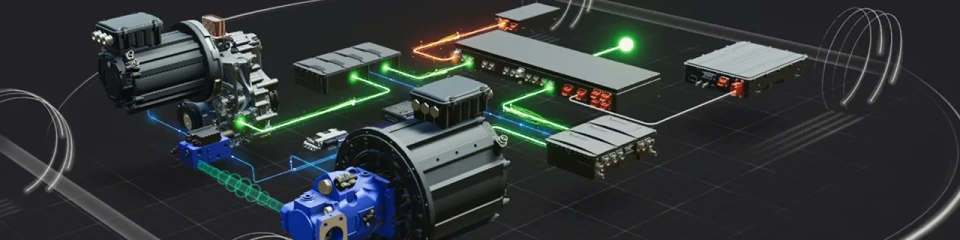

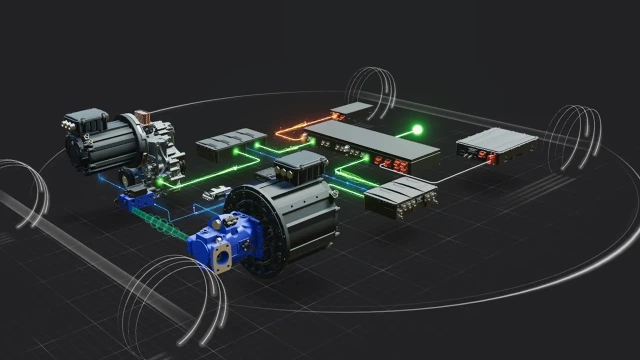

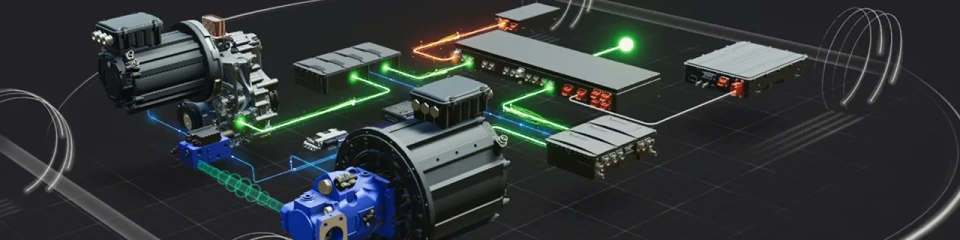

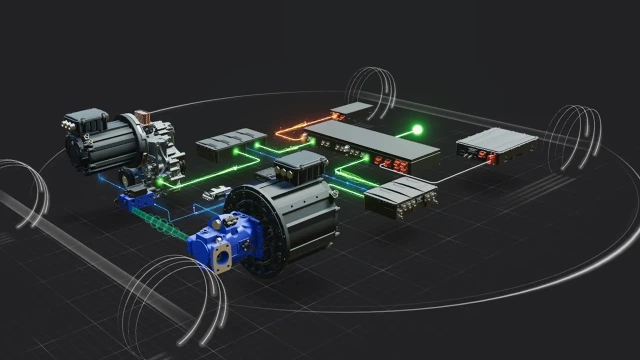

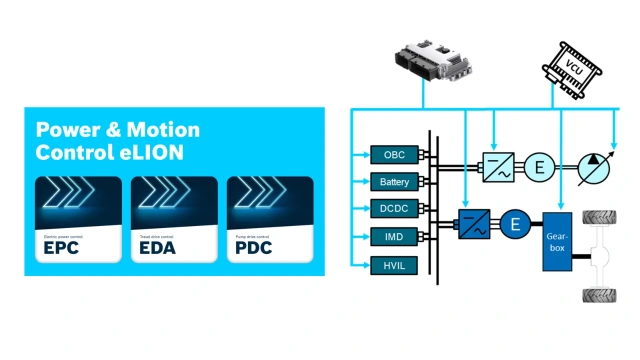

Many OEMs invest heavily in developing their own control software and find the effort in development, integration, and maintenance increases with each electrified model. This doesn't have to be the case. With the eLION Power and Motion Control portfolio, Bosch Rexroth now offers a cost-efficient alternative with a unified software logic across all machine sizes. Whether it's a new development or the conversion of existing vehicles, such as for rental fleets: integration is faster and more reliable with the portfolio specially developed for off-highway applications. At the same time, the complexity of electrification is reduced while optimizing machine performance and ensuring a needs-based operating experience. The solution approach – fitting for the BODAS Ecosystem – is modular and consists of three application software solutions that can be flexibly adapted to various applications:

Electric power control EPC

Controls the high-voltage system, communicates via standardized interfaces with battery and thermal management, and ensures electrical integrity. The integrated Power Management is optimized in terms of functionality and availability.

Travel drive control EDA

Controls the traction drive and enables both speed-based and load-sensing driving. This allows, among other things, the familiar operating feel of a hydrostatic drive to be precisely replicated.

Pump drive control PDC

Integrates the inverter, motors, and pumps with electronic control. In addition to pump control, the application software offers a variety of functions for energy-efficient and low-noise operation.

Conclusion:

The new eLION Power and Motion Control portfolio enables fast time-to-market and reduces development costs through pre-validated functions for high-voltage systems, traction, and pump drives. The portfolio integrates Rexroth eLION components such as inverters, motors, onboard chargers, and DC-DC converters. It allows optimal vehicle control and offers customizable interfaces to battery management and thermal management systems. Market launch began at the end of 2025, and initial pilot projects are already underway.

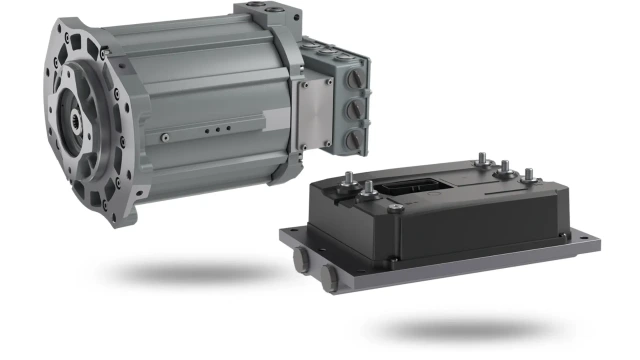

Same installation space, with up to 50% more power – that's how simply the new EMP1 motor series can be described. With this expansion, the eLION high-voltage portfolio grows to include a scalable off-highway-optimized motor platform for highly efficient pump drives, traction, and generator applications. The significant increase in power density with substantially higher traction force and lower gear ratios is based on an optimized electromagnetic design. The result: more compact, lighter, and more powerful machines. With five lengths, the scalable high-speed motors cover a continuous power range from 30 to 175 kW and impress with consistently high performance across the entire speed range. This opens design flexibility: every type of drive can be optimally supported – with higher machine efficiency and longer battery life.

Many manufacturers consciously begin the transformation with compact machines in the 96-volt range – for example, with wheel loaders or telehandlers. Others are already active in the high-voltage segment and now also want to electrify smaller power classes. That‘s why Bosch Rexroth complements the eLION Power and Motion Control portfolio with a 96-volt offering. This includes motors and inverters with CAN-J1939 communication, UDS diagnostic protocol, and fully integrated functional safety according to ISO13849. Thanks to these standard interfaces, manufacturers of mobile working machines benefit from a consistent communication and diagnostic infrastructure, which also significantly simplifies later scaling to higher voltage classes and power categories.

Contact us! Let's find an efficient and powerful solution together.

info.electrification@boschrexroth.de

The entire eLION portfolio and more information at a glance? www.boschrexroth.com/eLION