Products

OverviewIndustries

OverviewService

OverviewBuy

OverviewCompany

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewEDI (Electronic Data Interchange)

OverviewJob opportunities

Overview

The snow blowers from the Swiss manufacturer Zaugg are known worldwide for their reliability. With the IoT telematics package BODAS All-in-One Connectivity from Bosch Rexroth, the fleet will also be future-proof.

Whether it’s roads, railway tracks, or airports, it is important for traffic routes to be reliably cleared of snow and ice in the winter. ZAUGG AG EGGIWIL, a Swiss manufacturer, has developed a wide range of high-quality clearance equipment, which is supplemented by municipal services vehicles and devices for slope maintenance, such as the “Pipe Monster” for preparing snowboard half-pipes.

Founded in 1893, the company has developed from agricultural equipment for the regional market into an international exporter in around 40 countries. The expansion into North America is currently continuing, meaning the manufacturer with around 170 employees has to support an increasingly globally distributed fleet. “Five years ago, we reached a point where we realized we could only ensure and improve service quality with a suitable IoT telematics solution,” recalls Dominik Schmid, customer service manager at Zaugg. “New exhaust emission standards and the increasing proportion of vehicle electronics and software create new sources of error. At the same time, customers expect unlimited availability and minimum downtime.”

In addition, there was a specific customer request for a fleet management system with which current operational records can be generated based on usage data such as machine parameters or route information. “Without a suitable IoT telematics solution, we would have risked being excluded from future tenders or jeopardizing our market position due to excessive support costs,” explains Dominik Schmid on the relevance of the requirement. “Another incentive was the possible acquisition of machine data with the solution, which we could then use to further develop the vehicles.”

Simon Brechbühler, Head of Electrical and Hydraulic Engineering at Zaugg, in front of the telematics-enabled and IOT-enabled Rolba 500 self-propelled snow cutter blower. BODAS Connect’s OTA services shorten the support process. The transmission of machine data enables usage-based billing. (Image: Zaugg AG)

Zaugg had in-depth talks with its technology partner Bosch Rexroth about introducing an IoT portal. The decision in favor of the BODAS All-in-One Connectivity solution was based on the modular and open design and solid core components such as the robust BODAS Connectivity Unit by Bosch Rexroth, or RCU, developed for use in off-highway vehicles. Another module is the Bosch IoT Suite, a comprehensive software platform for IoT applications that provides basic middleware functions for demanding IoT applications in the form of cloud services, and which is well-established in high volume production. “Consistent and secure over-the-air services such as software and firmware updates, parameter readouts, and error diagnostics were particularly important to us,” adds Simon Brechbühler, Head of Electrical & Hydraulic Engineering at Zaugg. “With these over-the-air (OTA) services, we can deliver effective remote support and prepare well for service call-outs.”

Dominik Schmid

Customer Service Manager at Zaugg

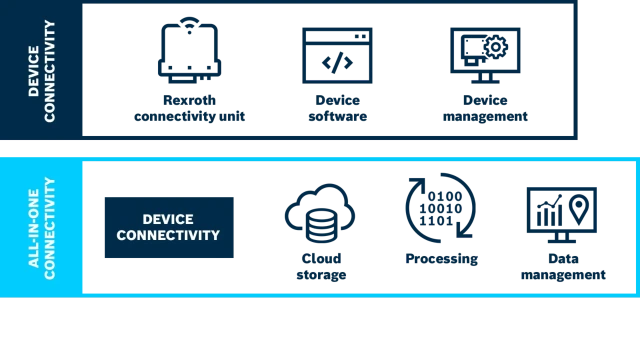

Modular concept: The sequential Device Connectivity and All-in-one Connectivity packages of BODAS Connect allow scalable IoT telematics solutions to be set up quickly and according to requirements.

Time is the most important factor to keep roads, railway tracks, and airports safe. Rapid troubleshooting by remote diagnosis is therefore crucial added value for Zaugg. The Rexroth BODAS Connectivity Unit (RCU) connects the machine to the IoT infrastructure of Bosch or a third-party provider and at the same time serves as a basic component for Bosch Rexroth’s modular IoT telematics solution. The RCU, available in three series tailored to different needs, covers a broad spectrum of requirements from simple IoT and telematics applications to complex scenarios with the highest demands on function and performance.

The container-based device management of BODAS Connect provides Zaugg with a variety of over-the-air services such as updating the RCU software, including providing new functions (software over the air – SOTA). In addition, firmware updates (firmware over the air – FOTA) can be rolled out to to controllers (ECU) and displays by Bosch Rexroth as well to devices from third party vendors. This is possible both for individual controllers and for complete fleets (campaign management).

The second task of the RCU is to gather machine data, filter, aggregate and compress it for an effective transmission to the cloud-based data management to enable data-driven services. Zaugg opted for Bosch Rexroth in this case too: The BODAS All-in-One Connectivity – Rexroth´s end-to-end data management solution is based on the Bosch IoT Insights cloud service, which collects, processes, and stores the IoT data for further analysis. Customized user interfaces for fleet management, operational monitoring, rental, or remote maintenance can be set up quickly thanks to a large number of predefined tiles.

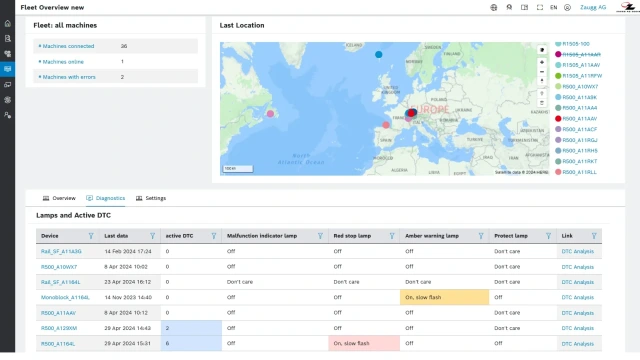

Zaugg customer service dashboard with the fleet overview, realized with standard modules (Image: Zaugg AG)

IoT data management is the foundation for optimizing devices and functions as well as developing new services and solutions. The machine data displayed in the user interface can be retrieved, selected, and evaluated using standard routines. This includes the option to insert your own routines, meaning the work data can be prepared perfectly for each customer – whether it’s for onward billing, scheduling, and job planning, or to estimate the service requirements.

View into the Rolba 500 control cabinet with the Rexroth controller RC28 (top right) and Rexroth connectivity unit RCU (next to it on the left). (Image: Zaugg AG)

In order to test the end-to-end solution without an investment risk, Zaugg used a starter kit from Bosch Rexroth first and determined all relevant data for further evaluation. The BODAS Connect support team assisted Zaugg in configuring the views and diagrams at the start.

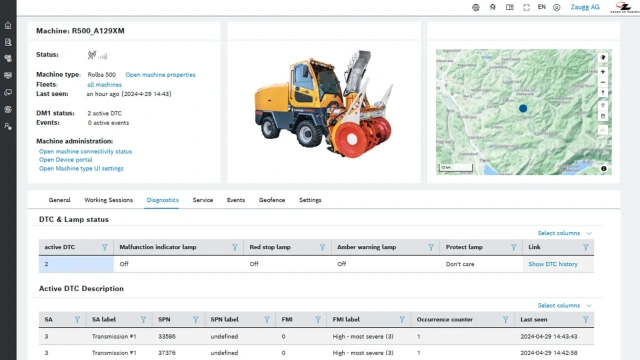

Following promising tests with the Rolba 1500 self-propelled snow cutter blower, the RCU was initially introduced in the Rolba 500 series. Using OTA, the service can display temperatures, pressures, and error messages with texts, flash the RC28 controllers’ software, and thus transfer new software functions to the machine. The end user has limited access to important information such as filling levels, fuel consumption, positions, and travel routes through the specifically adapted Bosch IoT Insights portal.

Zaugg intends to gradually expand the solution to the entire machine portfolio. After the Rolba 1500 series, the Monoblock snow cutter blowers for wheel loaders are next on the agenda. An installation is also already in place for railway track clearing equipment and vehicles. “Even if a problem cannot be solved remotely, service calls will become more efficient thanks to valuable up-front information,” says Dominik Schmid, who estimates that the time saved in support will be between 20 and 80 percent, depending on the case.

Single view of a Rolba 500 with links to detail pages, such as the error history (DTC History). (Image: Zaugg AG)

The speed with which an error can be rectified remotely was demonstrated by a specific malfunction last winter. “After querying the serial number, we narrowed down the system using Bosch Rexroth’s DOTA (diagnostics over the air) tool and asked the driver to check the plug-in connections,” recalls Simon Brechbühler. “The cause turned out to be a defective proportional valve solenoid on the hydraulic block. The driver replaced the coil using the on-board emergency kit and was able to continue work. Without remote diagnosis, the analysis would have taken a lot of time and would probably have involved a service call.”

For Zaugg, the IoT connection is the prelude to an even smarter future. “A generational shift is currently taking place at customers,” says Dominik Schmid. “The trend is toward predictive maintenance.” The IoT telematics project with Bosch Rexroth provides the necessary transparency. In addition, BODAS Connect enables gradual market introduction or retrofitting in each segment, for example for existing railway vehicles. “Our customers’ reputations are directly dependent on our machines’ productivity. With the robust, secure, scalable, and expandable solution from Bosch Rexroth, we can continuously increase our service quality, our market position, and our sales.”

Freedom of choice in hardware: The Rexroth BODAS Connectivity Unit (RCU) is available in three series: While the RCU 5 is ideal for simple applications as a basic connectivity solution, the Linux OS-based RCU 10 offers advanced mid-range features. The RCU 20 with quad-core processor meets the highest demands for function and performance, including complex systems and algorithms.

The RCU, available in three series, is the heart of the BODAS Connect solution and connects the machine to the IoT infrastructure of Bosch or a third-party provider. It collects, processes, and transfers vehicle data to the cloud with optimum bandwidths and enables modern over-the-air services (OTA). The housing of the IoT telematics unit developed for off-highway applications is designed in protection class IP67. The layered device software based on an open source Linux OS enables OEMs to protect their expertise and subsequent transfer to another hardware platform.

Author: Thomas Bruderer

Position: Sales Europe Middle, product area Mobile Applications, Switzerland

Phone: +41(55)4646-245

Cell: +41(79)1011338

Thomas Bruderer

Already connected on LinkedIn?

Thomas Bruderer

Bosch Rexroth AG