Higher performance, relief and greater flexibility when carrying out automation tasks

The future of automation lies in industrial ecosystems. Bosch Rexroth will demonstrate this with ctrlX AUTOMATION at HANNOVER MESSE (Booth C26, Hall 6) from May 30 until June 2. The partner network is growing all the time, adding hardware to the automation solution and an increasing number of apps which are available from the ctrlX Store. At the trade fair, two partners will demonstrate their integrated solutions, e.g. for high-end software engineering and for seamless OT-IT integration. Bosch Rexroth will also present new versions of its compact control system ctrlX CORE.

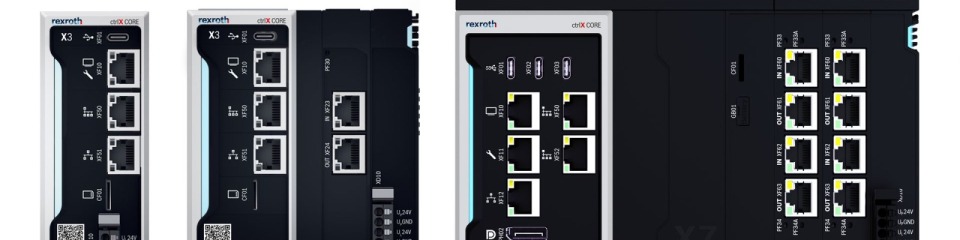

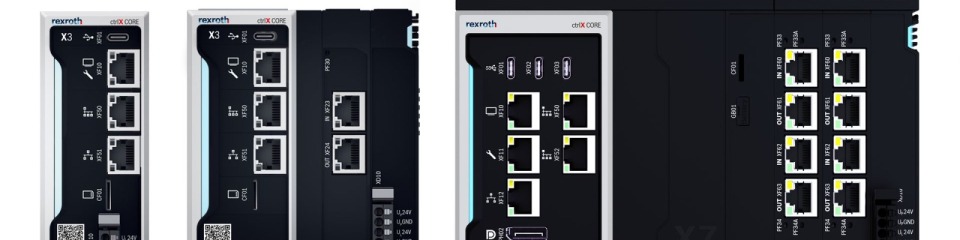

“We’ve raised our control portfolio to a new level. One of the products we’ll present is ctrlX COREplus which has been available since April 2022. This modular version of the compact, high-performance control platform from the ctrlX AUTOMATION portfolio offers not only additional fieldbus interfaces but also the option of arranging I/O modules in rows. In 2022, a new, extremely high-performance version of ctrlX CORE will revolutionize the market. Using cutting-edge CPU technology, it will offer approximately 7 times the performance of the previous ctrlX CORE,” explained Steffen Winkler, Vice President Sales, Business Unit Automation & Electrification Solutions at Bosch Rexroth

Bosch Rexroth will round off the ctrlX CORE product family with an entry-level version with a reduced number of interfaces and options. As a result, there will be a suitable control system for every application.

Engineering from the web

Bosch Rexroth also provides a wide range of functions for the software and engineering toolbox ctrlX WORKS. These make it possible to make engineering processes even more efficient. Among other things, it will be possible to execute docker images on ctrlX CORE. And development can now take place directly on the ctrlX CORE software thanks to a development environment for Python and Google Blockly which is integrated into the control system.

Steffen Winkler said: “Our software and engineering toolbox makes it easy to create, provide and use functions. It makes full use of web technology for this. The possibilities for users will be significantly increased as a result. Virtual engineering can be carried out on ctrlX CORE itself via a web browser. A comprehensive portfolio of libraries and building blocks for typical automation tasks is also available. For example, recurrent engineering processes can be automated via simple scripts. This will reduce the work involved by 80 to 90 percent.”

More apps – more service

The automation solution ctrlX AUTOMATION is designed to provide relief on various levels. ctrlX SERVICES play a key role here as a central element with digital and classic services. Bosch Rexroth has also further expanded this area so that users enjoy support over the entire product life cycle.

Steffen Winkler explained: “In the ctrlX Store, the number of apps from Bosch Rexroth and third-party providers is growing all the time. As a result, automation tasks can be carried out more easily and the requirements as regards future technologies such as AI, 5G and simulation solutions can be met. The ctrlX World ecosystem now has 50 partners.”

Numerous competencies in one world

At HANNOVER MESSE, there will be two ctrlX World partners at the Bosch Rexroth booth, where they will show their integrated solutions.

As a digitalization partner and expert for high-end software engineering, the company XITASO offers advice to B2B customers and implements solutions for digital added value in products, processes or production. The company focuses on mechanical and plant engineering. XITASO offers individual support when integrating ctrlX CORE into new or existing production environments.

Another partner, Bosch Global Software Technologies, provides support for the digital Factory of the Future. The DeviceBridge solution allows seamless OT-IT integration and collects production data from a large number of workshop machines, regardless of their generation. The data collected are pre-processed, converted into a standard format and passed on to IT applications such as MES, databases, clouds, file storage facilities and others for further processing and storage. The solution is compatible with a range of platforms and helps to avoid data losses.

“Together with our partners, we’d like to take advantage of HANNOVER MESSE as an opportunity to show that automation is now much more important than it was two years ago. It’s not just about automating processes – we’re helping companies to move towards the digital factory and achieve added value in this new world – on the basis of a clever ecosystem,” said Steffen Winkler.

The control platform ctrlX CORE is nominated for the Hermes Awards 2022.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, more than 31,000 associates generated sales revenue of around 6.2 billion euros in 2021.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,600 associates worldwide (as of December 31, 2021). The company generated sales of 78.7 billion euros in 2021. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 76,100 associates in research and development, of which more than 38,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de