The French group BFR Systems offers turnkey solutions for the production, packing and monitoring of products for everyday consumption. These solutions range from simple machines to complete lines. The Group is well regarded for its integration competences in this regard. The joint management of PLC and robot functions via control technology from the ctrlX AUTOMATION portfolio from Bosch Rexroth considerably simplifies the machine architecture.

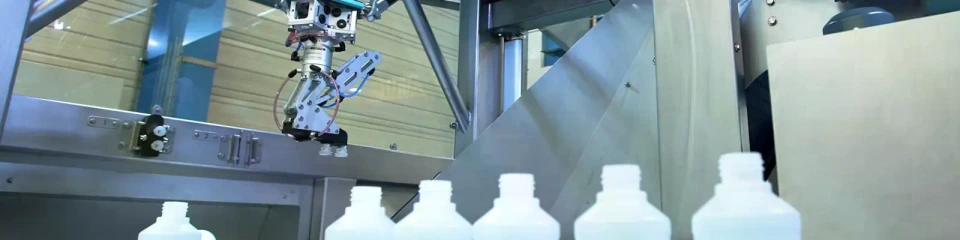

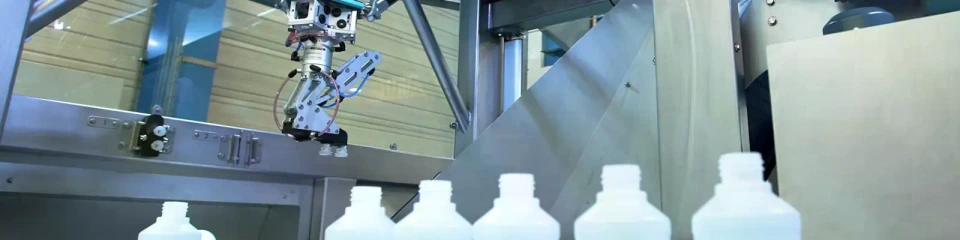

Its brand new robotic unscrambling unit for bottles allows to pick up tipped bottles in bulk and then deposits them on a conveyor one by one in order to feed a filling machine. The focus of development for food, cosmetics, hygiene and household products are optimized standard solutions that can be easily adapted to individual customer requirements.

Traditionally, unscrambling units rely on mechanical solutions for picking up, guiding and positioning plastic vials and bottles. Here a delta robot retrieves the packages in the loading area one by one and moves them to the conveyor belt.

"We have chosen to create a robotic unscrambling unit because this agile solution provides two advantages in comparison with 100% mechanical solutions: versatility and ease of use. This machine is designed to adapt to different types and shapes of bottles or vials, without the need for format parts," explains Thierry Fouré, Business Development Leader at BFR Systems.

Control system simplifies integration

"BFR Systems has chosen to integrate the automation and the Bosch Rexroth motion control on delta robot mechanics which were supplied blank. Here, we provided the motors, the servo drives and the control system for the complete implementation of the application," summarizes Nathanael Briand, application engineer at Bosch Rexroth in France. This architecture not only allows shorter development times, but also works in combination with any robot kinematics.

"Managing the automation and the robotic functions in one unique control system simplifies the architecture of the machine. In this way, we save development and commissioning time," explains Olivier Lecorre, Head of Automation Services at BFR Systems.

"The Bosch Rexroth control system is what allowed us to obtain the best trajectories. It’s a key element of this machine: we need optimized and fluid movements, and they need to be as smooth as possible. This is what will prevent bottle or vial losses," he adds.

BFR Systems uses controls from the ctrlX AUTOMATION portfolio for this purpose, which enable operation based on a real-time Linux kernel using apps and the provision of secure IoT functions. Programming can be carried out in various languages, from conventional PLC programming languages to high-level languages such as Python, C++ or C#.

"Using our platform ctrlX AUTOMATION, the machine manufacturers can easily record the user’s production data, perform diagnostics and remote maintenance, or even connect the machines to a MES tool," explains Nathanael Briand.

"It’s important for us to be able to connect our machines, create custom control panels, and offer remote maintenance without additional materials. ctrlX AUTOMATION works in the sense that we want to develop: complete, modular and dynamic lines which are adapted to suit the needs of our clients. This is also exactly why we chose Bosch Rexroth," concludes Olivier Lecorre.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, around 32,600 associates generated sales revenue of 6.5 billion euros in 2024.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 418,000 associates worldwide (as of December 31, 2024). The company generated sales of 90.3 billion euros in 2024. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 490 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 87,000 associates in research and development.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de