CNC system MTX can be combined with ctrlX AUTOMATION toolkit

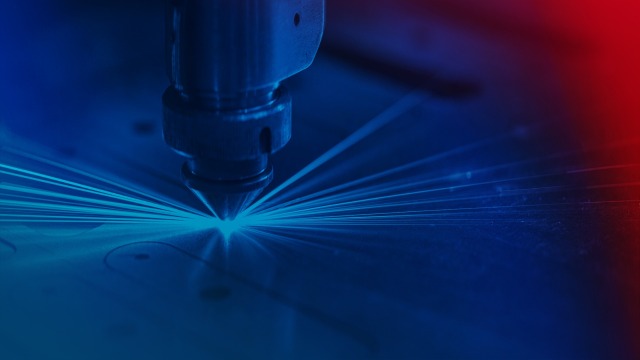

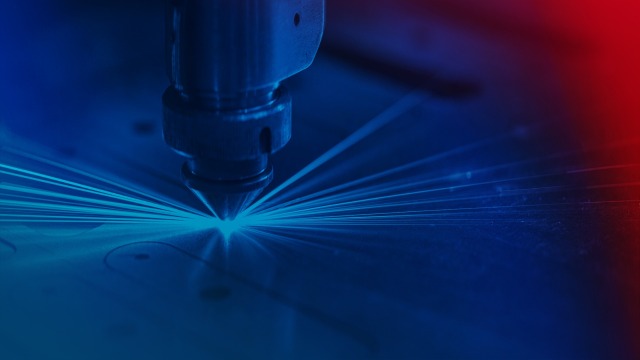

Manufacturers of CNC laser and plasma cutting machines are keen to significantly reduce their development times and time to market. The CNC system MTX from Bosch Rexroth helps to make this possible, for example with functions for straightforward engineering. In combination with the compact and modular drive system ctrlX DRIVE from the ctrlX AUTOMATION toolkit, it saves space and allows a high degree of scalability. Interaction with the control platform ctrlX CORE also aids connectivity and communication in Industry 4.0 – factors which are increasingly important nowadays.

“Beam cutting machines need to work quickly, precisely and reliably. At the same time, manufacturers must get their machines onto the market ever more quickly in order to remain competitive. Our CNC system MTX helps here. Among other things, it has a ready-to-use project template and high-performance functions for efficient laser cutting, e.g. height regulation, fly cut and leapfrog. This reduces not only the engineering time and costs but also the work involved if debugging is required,” explained Peter Berens, Head of Business Development Manufacturing, Business Unit Automation & Electrification Solutions at Bosch Rexroth.

Thanks to technological features such as leapfrog or frog jump, the high-performance CNC control system and suitable drive functions, users benefit too:

A reference metal sheet can now be cut 10 to 15 percent faster than before. The combination of high-performance multi-core processors and decentralized intelligent drive technology makes MTX the most powerful CNC system on the market. As a result, very high cutting speeds and acceleration are possible with maximum precision.

This solution is used in typical applications in the area of beam cutting, e.g. 2D laser cutting, plasma cutting or water jet cutting. With Industry 4.0 communication features in accordance with the OPC UA standard, the system is also ready for the world of digitalized factories.

Double power thanks to a combination of solutions

“Our solutions are open in all directions. As a result, the CNC system MTX combines perfectly with products from the ctrlX AUTOMATION world. For example, the MTX is often used together with ctrlX DRIVE, the world’s most compact modular drive system. This offers numerous advantages. For example, the automation structure and the system footprint can be minimized and energy-saving requirements can be met,” said Peter Berens.

The bundle allows quicker engineering with the engineering tool IndraWorks and offers functions for virtual commissioning and digital twins for simulation. Other solutions from the ctrlX AUTOMATION portfolio allow new scope of action and savings for beam cutting. The compact control system ctrlX CORE offers various advantages when it comes to Industry 4.0 connectivity. It provides additional functions and helps to ensure future viability. Bosch Rexroth will present all these benefits at hall 11, booth D08 at the EuroBLECH trade fair.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, more than 31,000 associates generated sales revenue of around 6.2 billion euros in 2021.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,600 associates worldwide (as of December 31, 2021). The company generated sales of 78.7 billion euros in 2021. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 76,100 associates in research and development, of which more than 38,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de