METEC

As an international industry gathering, the METEC is the exhibition event for the metallurgical technology of tomorrow! The METEC focuses consistently upon reflecting on challenges in order to recognise the requirements of the future. The best metallurgy experts in the world are meeting to exchange ideas and experience.

Reduce costs by digitalization and sustainability? YOU DECIDE.

Cost, quality, and speed are the relevant factors when investing in metallurgy and foundries. Bosch Rexroth offers intelligent, connected and sustainable hydraulic solutions that help you increase your productivity while saving energy and resources.

Our goal is to work with you to reduce your total cost of ownership, simplify your design, speed up commissioning, maximize your productivity and minimize downtime. With our extensive application experience, we will guide you on your way to sustainable and green production.

Bosch Rexroth is the perfect partner for the current and next investment cycle – time to make your systems fit for the future! Contact us now. We look forward to hearing from you.

We Move – You Win.

Visit us at booth E64 in hall 01.

METEC 23

Hall plan

Get your ticket

Enter your voucher and register

Your contact to Bosch Rexroth

Connectivity and Sustainability with added value

In metallurgy and die casting machines, plant investments are more than ever about cost and speed. Intelligent, connected and sustainable hydraulic solutions help you meet these challenges. They simplify design, speed up commissioning, maximize productivity and minimize downtime.

H4U – Hydraulics For You – The Intelligent Move

H4U – The software platform from Bosch Rexroth offers new freedom in mechanical engineering – increasing productivity and sustainability

Bosch Rexroth is taking the integration capability of industrial hydraulics to the next level and transferring previously hardware-bound control functions into hardware-independent software modules. Hydraulic functions can be flexibly designed through the new H4U (Hydraulics For You) platform and directly integrated into existing automation environments. This transformation to software brings numerous advantages for end users as well as machine and system manufacturers. Hydraulic systems can be tuned in an energy-efficient way and contribute to the achievement of climate targets.

Sytronix – THE ECO-BOOSTER

Variable-speed drive solutions: Less electricity, less noise, lower costs.

Everyone needs to help in the fight against climate change. Plant operators and machine manufacturers play a key role too – with new energy-efficient systems and retrofits to optimize the energy use of existing machines. Variable-speed drives have particular potential for improvement in this respect. Because they provide the required power with pinpoint accuracy and switch to standby in idle phases, they reduce energy consumption by up to 80 percent depending on the work cycle and avoid CO2 emissions accordingly.

SYTRONIX

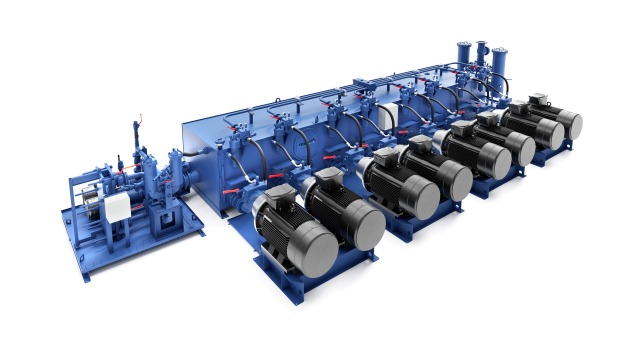

ABMAXX – TIME IS MONEY

Engineering for large power units reduced to five days

Simpler, faster, more productive, and more cost-effective: With the new ABMAXX modular system, Bosch Rexroth speeds up the engineering and commissioning of large hydraulic units for new construction and modernization of plants. But Bosch Rexroth is not losing sight of the issue of sustainability either. The wide range of variable-speed pump drives in the Sytronix family, for example, opens up considerable potential for reducing energy consumption in line with demand. This sustainably reduces life cycle costs. At the same time, a flow- and degassing-optimized tank can reduce the oil volume by up to 50%.

Experience the new benchmark for die casting machines

New generation of highly dynamic control valves

With the new generation of WRCE 4X high-response cartridge valves, Bosch Rexroth has reached a new level of technology. Larger volume flows make it possible to use smaller, more dynamic valves with the same machine size. The pilot-operated valves communicate with the higher-level machine control via a multi-Ethernet interface for all common, real-time Ethernet protocols.

Hägglunds Condition Monitoring

Connected systems can bring greater value to your business.

Condition monitoring with Hägglunds CM gives you an improved customer experience, enabling better decision-making and faster support.

All of this helps you to maximize the uptime from your Hägglunds drive system.

Experience the modern suite of products and services Hägglunds Inside Intelligence.