The Battery Show Europe

Finally live again!

The Battery Show Europe

June 28th - 30th , 2022, Stuttgart

Hall 8, Stand D70

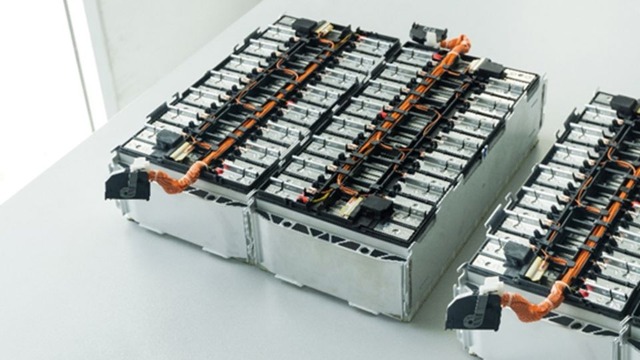

From individual components to software solutions to complete assembly lines for battery production, Bosch Rexroth offers everything from a single source. See for yourself at The Battery Show in Hall 8, Booth D70, our highlights such as the new TS7 transfer system, the new linear robots for a wide range of automation requirements, and the flexible transport system in conjunction with the ctrlX AUTOMATION platform.

Highlights

VarioFlow Chain conveyor system

Powerful, standardized and versatile

Today, the demands on transport solutions are higher than ever. Our comprehensive modular system opens up a wide range of combinations and solutions for the design of individual transfer solutions. The VarioFlow plus chain conveyor is up to any challenge, even in the tightest of spaces and speeds of up to 100m/min.

TS7

Boost your production

Due to the process, a non-accumulation transfer between the workpiece carrier and stop gate is required in battery production. Part of the extensive TS7 modular system is a segmented, zero back-pressure conveyor section that can accelerate and decelerate the workpiece carrier via an intelligent control system. The TS7 transfer system is the basis for handling large and heavy battery packs up to 1200 kg per pallet.

BENEFITS

- HIGH SYSTEM AVAILABILITY due to low-maintenance drive concept

- LOW NOISE level when running the machine

- Good efficiency results in HIGH ENERGY EFFICIENCY

- For each roll, the FRIKTION IS ADJUSTABLE without tools

- MODULARLY CONSTRUCTED transfer system with an extensive modular system and FAST COMMISSIONING

- ROBUST DESIGN: Suitability for particularly harsh manufacturing environments and high loads

- Designed for 24/7 continuous use

Modular and flexible high speed conveyor with FTS and VarioFlow

The battery cell manufacturing process requires a fast and flexible transfer system. The combination of the transport system FTS and the chain conveyor system VarioFlow maximizes flexibility, speed and cost optimization in the battery cell manufacturing process.

VarioFlow can be easily designed and adapted for any plant layout thanks to the planning software MTPro. The battery cells and associated material are transported quickly and safely to the individual process stations along the planned logistics path.

At the process stations (e.g. stacking, welding, filing, testing), the Flexible Transport System FTS takes over control for each workpiece carrier, enabling accurate positioning and synchronized movement for multiple carriers and process axes.

Linear Motor Transfer Systems

Battery EoL testing and recycling with ctrlX AUTOMATION

The compact and modular drive system ctrlX DRIVE and the control platform ctrlX CORE can be used as Sink and Source in End of Line testing,

and the same solution can be applied to battery recycling in the upstream process for battery discharge.

In combination with Bosch Rexroth transfer systems, new possibilities arise for industrial, automated battery production and recycling.

Smart Function Kits

Plug & Produce with the new mechatronic subsystems

The new linear robots - consisting of our best-in-class linear technology components, automation hardware and software - can be used for diverse automation requirements such as joining and pressing, handling or dispensing.

Modern eTools support the selection of products. The pre-installed, intuitive operating software enables fast commissioning and simple graphical process configuration without programming knowledge.

The subsystems can be easily integrated into higher-level systems through open interfaces and can be used in a wide range of applications through compatible end effectors, such as the sensor-based compensation module Smart Flex Effector.

ctrlX AUTOMATION

Automation without limits

Increasing productivity, efficient use of resources, improving quality and shortening time-to-market are important core factors in the field of battery manufacturing. The automation system ctrlX AUTOMATION meets these requirements by removing the classic boundaries between machine control, IT, and the Internet of Things. With the Linux real-time operating system, open standards, app technology, web-based engineering and comprehensive IoT connectivity, ctrlX AUTOMATION reduces component and engineering effort by 30 to 50%.

The open and flexible system enables the combination of existing and new product lines to create the perfect solution package.