Processes

Optimizing work processes, increasing production capacity or reacting flexibly to new product variants – tasks which the Bosch plants are faced with every day. You’ll find a range of solutions for various processes which you and your company can use here. Our specialist advice and application know-how are included.

Intralogistics

Broaden your focus and optimize your entire value stream: Automate and standardize internal transport tasks and create applications from cyclic to consumption-based line transport with our transfer systems.

- Plug & Go: Implemented quickly and easily without adapting the existing factory infrastructure

- Adaptive: Automatic map updates

- Safe: For materials, people and machines

- Flexible: Follows production and logistics processes, manually or automatically via third-party systems

- Robust: Designed for 24/7 mixed operation

- Efficient: Optimized logistics processes, less space and fewer materials needed, shorter throughput times

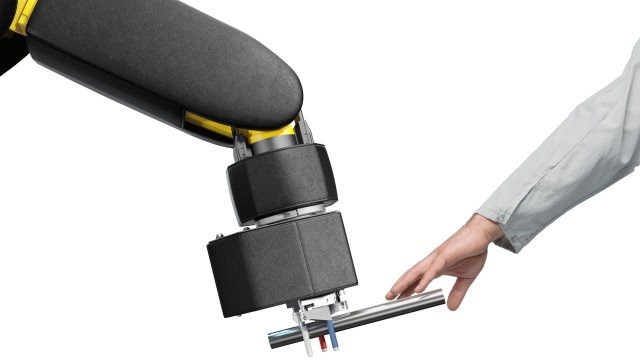

Handling

Whether you need to grip and position precisely with minimal cycle times, quickly retool systems for small batches or adapt flexibly to production changes: Efficiency and economy have top priority. Rely on our product range – from individual Pick & Place components to complete palletizing solutions and cobots.

- Predefined kits comprising perfectly tailored hardware components and software

- Straightforward product selection and configuration

- Single or multi-axis system kits

- Automation hardware (drive controller, control unit and servo motor)

- Intelligent, safe and fast cobots for flexible production

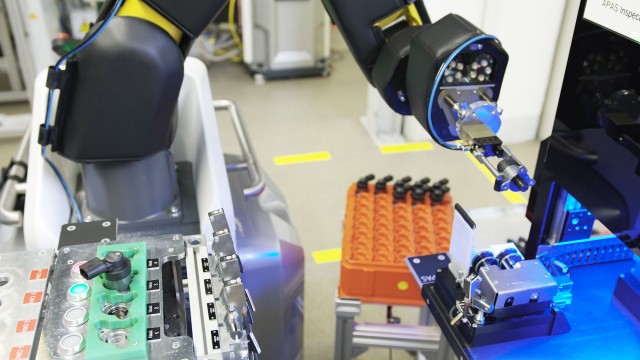

Automating processes

Adapt with the help of production modules: Assembling, joining, forming, checking or testing – our production and assembly assistants support you whatever the lot size and increase your profitability and productivity. Integrate flexible function modules into your existing lines.

- Predefined kits comprising perfectly tailored hardware components and software

- Preselected mechanical, electrical and software components are bundled together in various kits for forces from 2 to 30 kN

- No programming knowledge required

- Intelligent, safe and fast cobots for flexible production

Packaging

Our automated packaging solutions combine performance and flexibility. We thus help you to maintain your competitiveness in spite of constantly changing customer requirements. Our reconfigurable assistant systems allow you to meet all market requirements flexibly – especially when it comes to co-packing.

- Fully automated systems for more flexible packaging processes

- Transportation, handling, assistance and quality assurance

- Linking of production systems and line integration of process steps

- Intelligent, safe and fast cobots for flexible production

Increase productivity

Control your processes according to your individual needs: With the modules from our automation platform, you overcome the typical boundaries between machine control, the world of IT and the Internet of Things. System functions and electrical drive components are perfectly tailored to each other and can be integrated directly into the machine.

- The most open automation system on the market

- Unique IoT integration

- Future-proof with 5G, TNS and OPC UA

- Certified security solution in accordance with IEC 62443

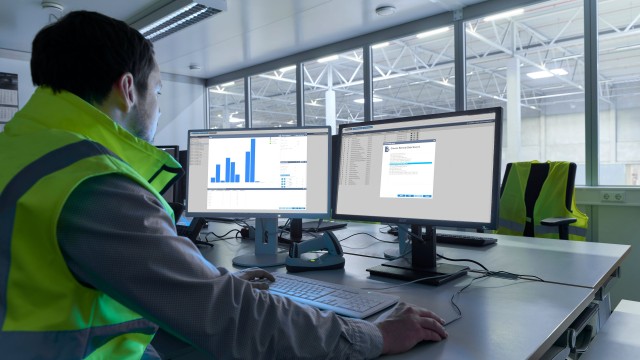

Digital shop floor solutions

Ensure transparency: With an interactive communication platform and localization solutions, you can monitor operating states and processes. Complete your line with efficient and automated quality control that fits seamlessly into an intelligent material flow.

- Robust 3D imaging process

- Robot technology without safety enclosure for quality assurance

- Efficient and paper-free CIP rounds

- Processing and presentation of production data in real time