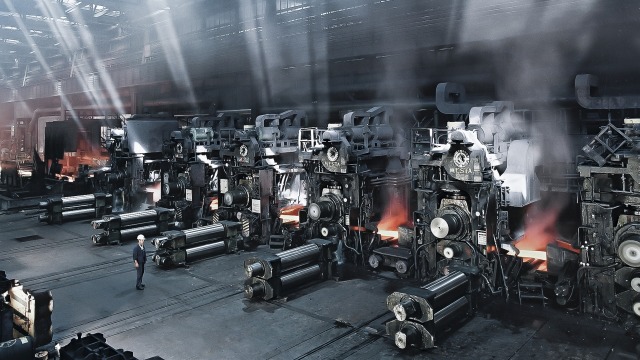

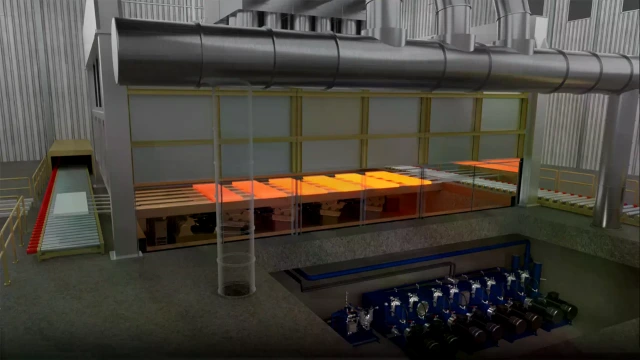

Reliability, total cost of ownership, and safety are just a few relevant factors when making metallurgy expenditures. Bosch Rexroth hydraulic solutions for steel mills and foundries increase productivity while conserving energy and resources. Whether for ferrous or non-ferrous metals, Bosch Rexroth delivers optimal drive solutions for all production steps, such as melting, converter processes, casting, rolling, and surface treatment.

Contact us now

We know our technologies inside out. That means we can quickly find the right solution for your metallurgy task.