Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

Overview

Linear guidance: 5 reasons to choose Rexroth rail systems

In a world where linear conductors or rail systems are commonplace and can be bought on almost every corner, it is almost impossible to stand out. Nevertheless, we think that we have succeeded in this at Bosch Rexroth. Read on to see our reasoning.

Number 1: Interchangeability of carriages and rails

We'll start right away with the most important! The interchangeability of the carriages and rails. Our carriages and rails are made with such small tolerances that it is unnecessary to create “rail-carriage sets”. In other words, all carriages will fit on any rails without loss of accuracy or bias – and this is true for all our ranges. This increases your flexibility in terms of design planning and stock management, or with any later adjustments. Also, after the mechanical life of a carriage, you need only replace the carriage; the rail can remain in place without sacrificing accuracy.

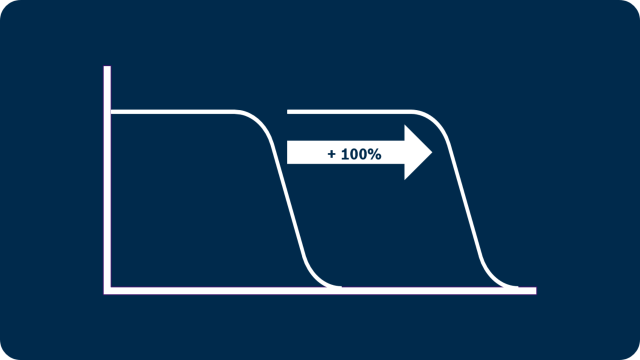

Number 2: Doubling the service life

With our patented “high precision” ball trajectory technology, we achieve a number of significant advantages over conventional carriages. Firstly, a 26% load capacity increase, resulting in a doubling of the lifespan, and therefore, secondly, you have the possibility to "downsize" your rail system with all the positive results that come with it.

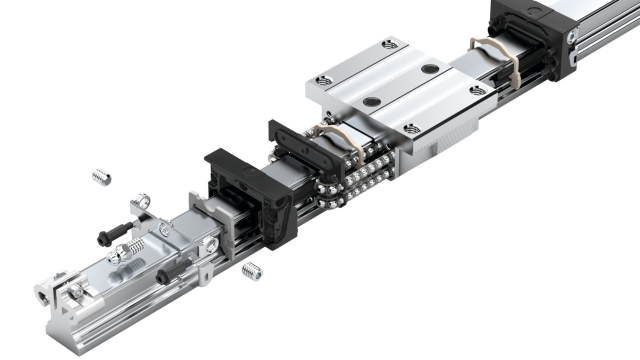

Number 3: Quality, down to the smallest details

The difference between a "good rail system" and a "perfect rail system" is in the smallest details, and we know that all too well! This attention to detail goes far at Bosch Rexroth – we’ve already mentioned that the ball tracks in our carriages are patented. But there are more details that increase the quality, for example the thread for the grease nipples is not tapped in plastic (which is common in the market), but in metal.

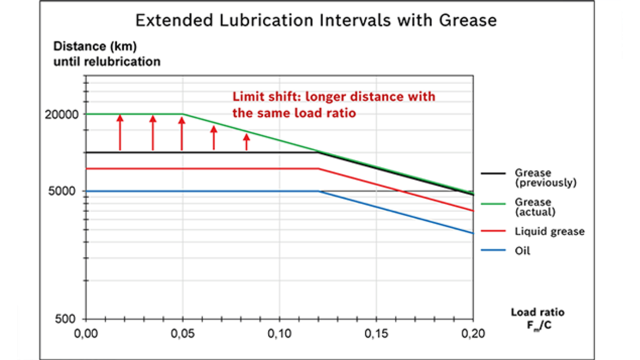

Number 4: Extra long lubrication intervals

The all-important “greasing intervals” should not be missing from this list. This is also one of the areas where Bosch Rexroth has made great strides lately. By doubling the lubrication intervals of the rail systems, the carriages can now cover 20,000 kilometers before needing to be lubricated again.

Number 5: A complete (accessory) program

A complex and efficient program supports all of our rail systems. With the 8 different rail sizes and a variety of carriage designs, it is practically impossible to go wrong. Do you want an integrated measuring system with the accuracy of a glass scale?! No problem, just use our program. Runner blocks suitable for speeds of 10 m/s or accelerations of 500 m/s²? That’s no problem either. And when it comes to accessories, you’ll have no trouble; whether scrapers, seals, clamps, bellows or cover strips… we have it!

You can easily configure Bosch Rexroth rail systems with the online configurator. If you are already a customer, you will immediately receive pricing information and delivery times for your configuration. It’s that easy! However, if you're not an expert yet and need help with your configuration, Linear Motion Designer can help – it’s the eTool that will get you started quickly and seamlessly.