Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

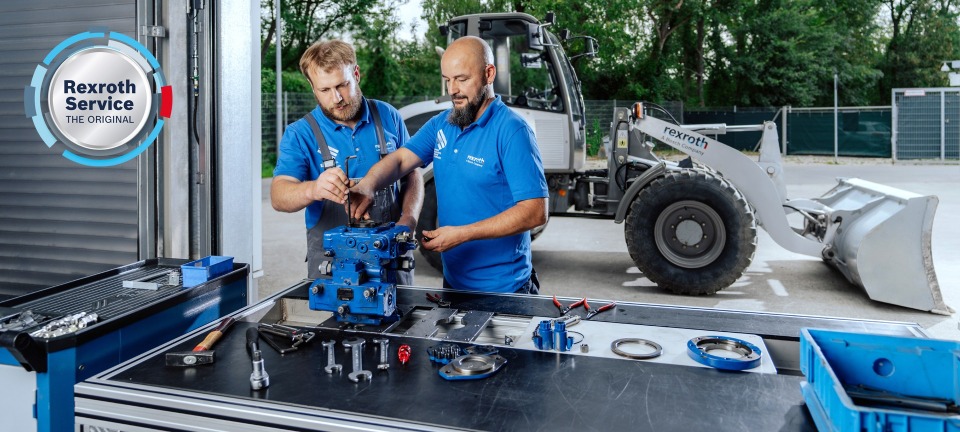

Service

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

Overview

United Kingdom

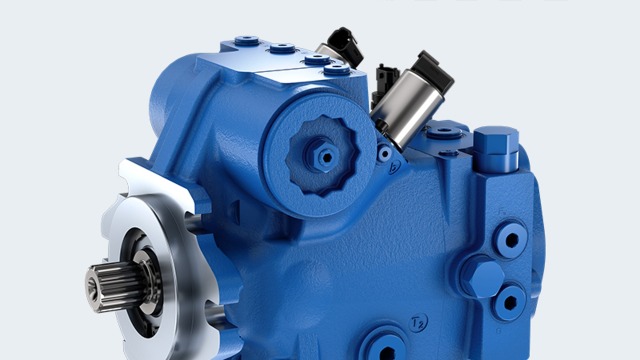

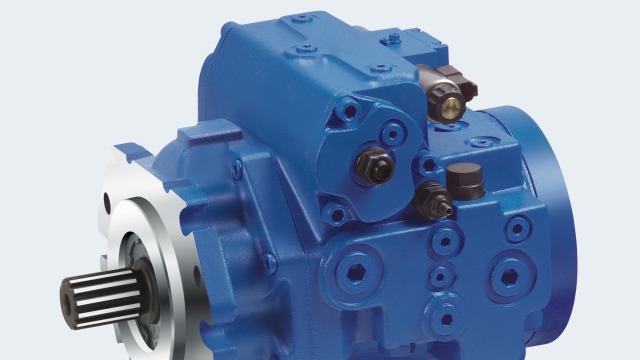

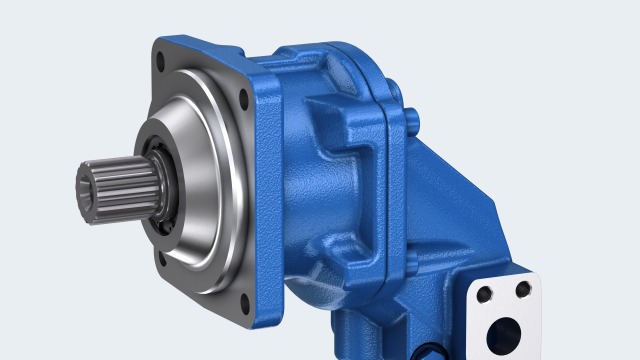

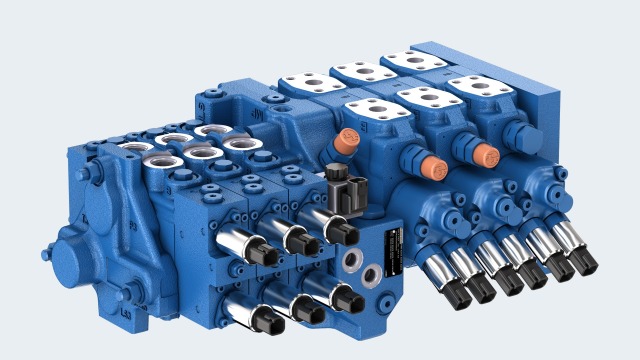

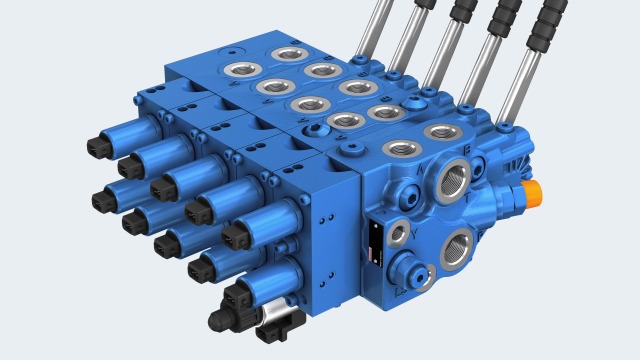

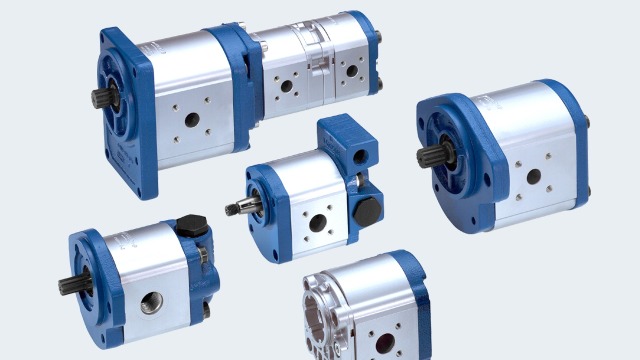

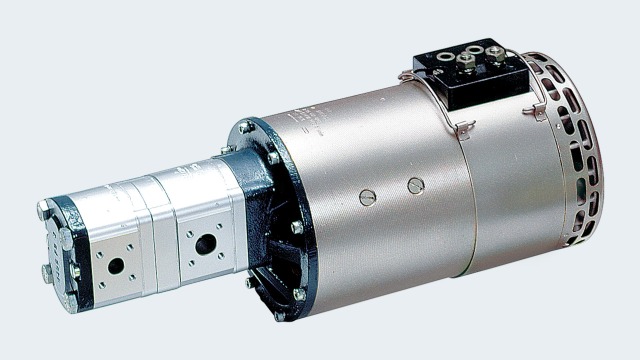

Mobile Hydraulics,

Electronics and IoT

Using electrified, electronic and digitally networked solutions, we are helping you to create the next generation of mobile machines. Our performance gives you access to increased power, safety, efficiency and intelligence.

Support

{{{tab-navigation-header}}}