For fast repairs, original spare parts, retrofit solutions or modernisation, contact us today.

When change is the norm, how fast can you adapt? At Bosch Rexroth, we empower you to engineer, scale and improve your factory and warehouse at the pace of your markets.

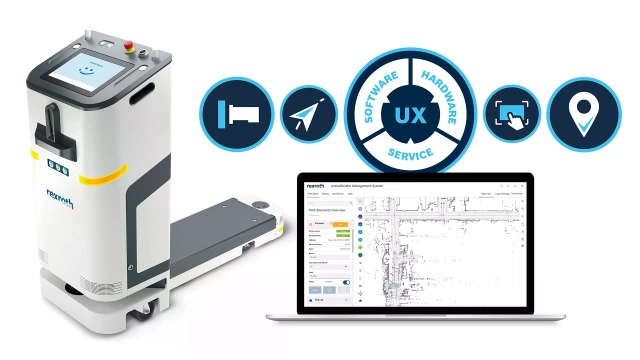

A fresh perspective on the future of mobile machine automation.

Explore our range of tools and configurators for Industrial Hydraulics and Factory Automation with our experts.

We are expanding our network of Certified Excellence Partners, making it quicker and easier for you to access our products and services.