automatica

As the world’s leading trade fair for smart automation and robotics, automatica brings together all key technologies in the international technology hub of Munich. This makes it a meeting point for constructive and visionary cross-sectoral exchange between industrial, research and political representatives. And there is more: It offers an overview of global developments, topics, innovations, and solutions, thus providing the necessary orientation and investment security in these times of upheaval. So that the vision of gradual advancement from automated to autonomous production may become reality – providing a growth opportunity for you and your company.

Finally we can welcome you live again.

This is what you can look forward to in Munich:

ctrlX AUTOMATION – Two Steps Ahead

The automation system ctrlX AUTOMATION surmounts the classic boundaries between machine controls, the IT world and the Internet of Things. With a Linux real-time operating system, consistently open standards, app programming technology, web-based engineering and a comprehensive IoT connection, ctrlX AUTOMATION reduces components and engineering costs by 30 to 50%.

Users can choose the perfect solution package for their needs in intelligent automation and robotics from the ctrlX AUTOMATION toolkit.

Simple engineering:

ctrlX AUTOMATION allows free choice of programming language. In addition to classic programming, such as IEC 61131, PLCopen or G-Code, modern low-code programming based on graphical program blocks is supported.

Smart Features & Apps:

The technology functions of ctrlX MOTION ensure higher dynamics and productivity. They provide important support, especially in handling applications. Active vibration damping, for example, protects the mechanics and enables maximum accuracy.

Perfect user experience with mobile HMI solution:

The panel frame from the ctrlX HMI portfolio is suitable for 10" consumer tablets. It is operated via web-based visualization. The enabling switch ensures safe operation and IT security is also guaranteed by a firewall.

The autonomous mobile robot (AMR) ActiveShuttle is already making entry into the factory of the future!

The Factory of the Future is completely flexible and connected – AMRs fit perfectly into this type of environment, delivering goods to the point of need, exactly where and when they’re needed. There’s an increasing demand for multi-variant and small batch production, and ActiveShuttle helps to solve this challenge, making intralogistics processes flexible but without having to change factory infrastructure.

MTpro Online Designer & FRAMEpro – the latest engineering tools for Assembly Technology

MTpro Online Designer – now create your assembly layouts with the online variant

With the online version of the proven project planning software MTpro for assembly systems, you can now plan independently of time and place. From component selection and configuration to material ordering.

FRAMEpro – the intelligent CAD plug-in

Working with Autodesk® Inventor or Dassault SOLIDWORKS? The CAD plug-in FRAMEpro brings the proven basic mechanical elements from Bosch Rexroth directly into your environment! This saves you a lot of time and avoids potential transmission errors!

TASS Verification System

TASS – inspection “on-the-fly”: Innovative verification system ensures quality directly in the production process!

Classic methods for the inspection of tightening tools are not very efficient and are at the expense of productivity. The TASS (Torque Angle Slip Standard) verification system developed by Bosch Rexroth provides an amazingly simple remedy by bringing the inspection of the tightening tool directly into the assembly process. With the new on-the-fly process, quality is assured directly at the workplace and the assembly flow is maintained.

World first Smart Flex Effector – sensor-based compensation unit for robots

Revolutionize your production and open up new industrial workflows with our Smart Flex Effector. The compensation module with active measuring function ensures greater precision in six degrees of freedom, e.g. in handling robots and Cartesian systems.

You can also benefit from the Plug & Produce approach of our Smart Function Kits.The new mechatronic subsystems consisting of our best-in-class linear technology components, automation hardware and software can be used for a wide range of automation requirements such as joining and pressing, handling or dispensing. The pre-installed, intuitive operating software enables quick commissioning and simple graphic process configuration.

Level Up Your Mobile Robots. ROKIT – The Robotics Kit by Bosch Rexroth

With its robotics kit ROKIT, Bosch Rexroth unlocks new possibilities in the field of mobile robotics and service robotics. The modular kit consisting of individual, coordinated and proven software and hardware components gives you the highest degree of freedom you need in the course of automating processes. The components – ROKIT aXessor, ROKIT Locator, ROKIT Navigator and ROKIT Motor – provide you with a graphical user interface and take care of positioning, navigation and motion execution for you. Supporting, product-specific services round off the user-focused portfolio.

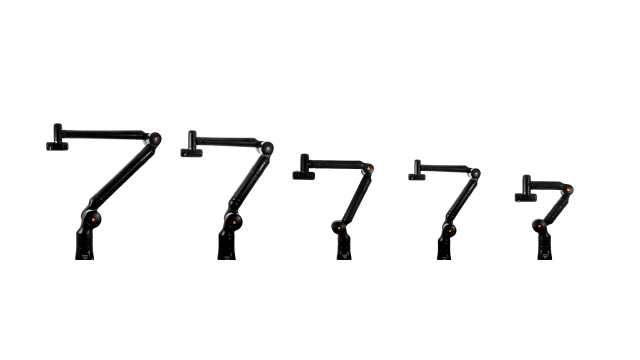

Kassow Robots collaborative robots with 7 axes: strong, fast, simple

With 7 axes, Kassow Robots cobots can grasp items around corners like an arm and can be used in the tightest of spaces. Designed for a wide range of industrial automation tasks, Kassow Robots cobots have reach up to 1800 millimeters and payloads up to 18 kilograms. All models are easy to program and operate. The software provides a modular platform allowing simple integration of peripherals like grippers, vision systems or other customized functionalities.

Cobots are another important building block for the versatile Factory of the Future. Bosch Rexroth acquired a majority stake in Kassow Robots end of April 2022.