SPS

Bringing Automation to Life: Hands-on. Visionary. Personal. With its unique concept, SPS covers the entire spectrum of smart and digital automation – from simple sensors to intelligent solutions, from what is feasible today to the vision of a fully digitalized industrial world.

Would you like to benefit from the most open industrial automation? YOU DECIDE.

Whatever your automation task, Bosch Rexroth has the right technology and the right people to support you and your goal.

At SPS 2023, see how you can benefit from Bosch Rexroth in your day-to-day operations and with your future challenges. Our solutions for factory automation with the consistently open automation toolkit ctrlX AUTOMATION are among the most advanced on the market.

Discover how you can sustainably improve the performance of your plants by selecting suitable technologies, solutions and lifelong services. With our technology, we give you the freedom to succeed.

Do you want to take advantage of this freedom? YOU DECIDE.

Messe Nuremberg, November 14th – 16th, 2023, Hall 7, Booth 450

Register here for the booth tour.

SPS 2023

Site map

Tickets

Your contact to Bosch Rexroth

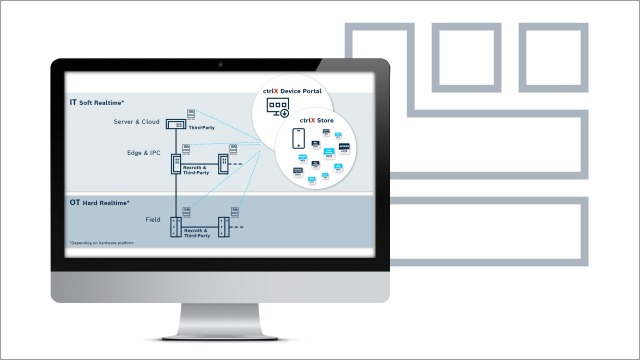

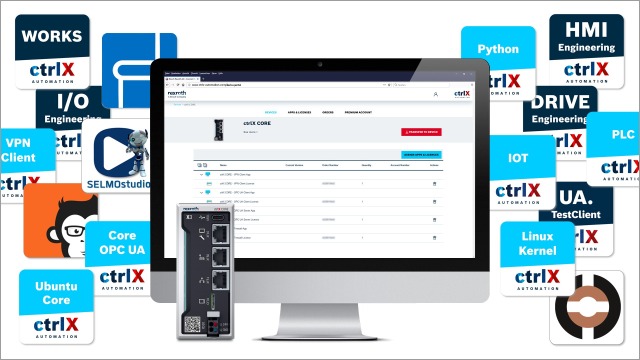

Maximum openness with operating system ctrlX OS

ctrlX OS is an operating system with digital services that sets completely new standards. It is based on the real-time capable Linux operating system, which is based on Ubuntu Core, is hardware-independent and can be installed directly on the respective hardware or also used in virtual environments. The possibility of "use for all" creates completely new opportunities for all parties involved.

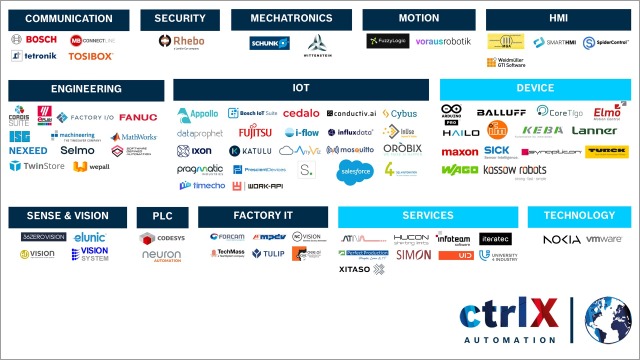

Wide range of solutions through partner world ctrlX World

The ctrlX World also stands for openness: The partner world expands the range of the automation toolkit ctrlX AUTOMATION with hardware and especially apps. All aspects of machine builders and users are covered in order to quickly engineer machines and operate them with as little risk as possible.

Once again this year, numerous partners will be represented at the Bosch Rexroth booth.

ctrlX FLOW: Open motion systems for transport & positioning

Automating and optimizing intralogistics processes is a key factor for the success of the Factory of the Future. With the ctrlX FLOW product family, Bosch Rexroth offers easy-to-integrate solutions for optimum and highly efficient material and goods flows. In addition to the planar system ctrlX FLOW6D for contactless high-performance conveying and positioning, Bosch Rexroth is presenting a new high-speed solution for transport and positioning in the modern factory at SPS.

Efficient software solutions

Simple engineering and maximum flexibility: The apps around ctrlX AUTOMATION as well as new software functions for virtual commissioning and simulation contribute to this. The possibilities of web-based engineering are being further expanded, enabling customers to save considerable time. With services along the customer journey, such as the ctrlX Device Portal and the ctrlX Configurator, users can also significantly reduce effort and costs.

Versatile control solutions

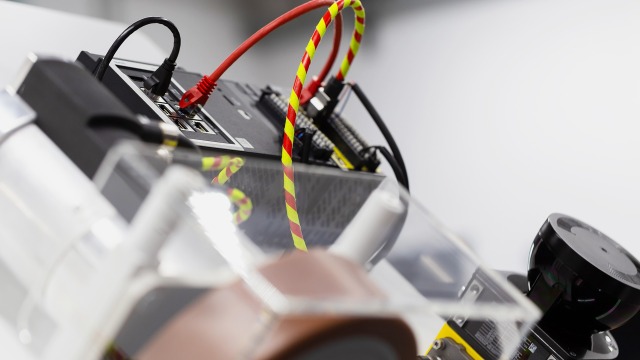

The right solution for every application: The versatile control and automation solutions such as the control platform ctrlX CORE, the I/O modules ctrlX I/O, the safety control ctrlX SAFETY as well as the industrial PCs ctrlX IPC and various HMI solutions ctrlX HMI can be used for PLC-based applications, IoT use cases or analytics and safety functions.

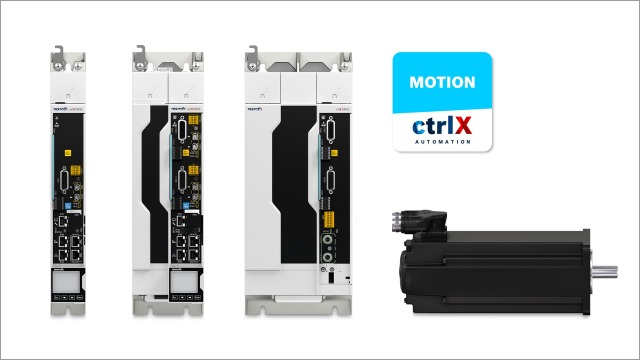

Dynamic and precise motion and drive functions

With ctrlX MOTION, a wide variety of automation tasks can be solved with high precision, ease and safety. With new function sets, e.g. for robotics applications, systems can be perfectly automated. The scalable drive portfolio is available to match – it now also covers the lower voltage range. Bosch Rexroth will also be presenting the new cabinet-free variant at the SPS, which means that there is no need for a control cabinet.

Energy Efficient Solutions & Remanufactured Products

Sustainability means the future! Bosch Rexroth offers a comprehensive range of tools and models for energy and performance simulations in order to optimize the design of systems. The portfolio is supplemented by product-specific features such as the Smart Energy Mode of the drive system ctrlX DRIVE. Product overhauls are another important component in favor of sustainability. The "Remanufactured Products" program aims to overhaul used parts instead of throwing them away, thus increasing their service life.

Automation solution for mobile robots

Mobile robots can be automated with software and hardware from ROKIT – The Robotics Kit and ctrlX AUTOMATION. The modules can be integrated step by step into the vehicles as required. Manufacturers and system integrators benefit from less development effort, cabling, interfaces and components.

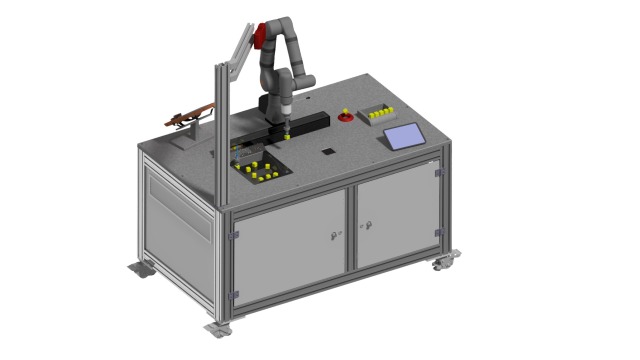

3D image recognition using Rexroth Smart Item Picking and Kassow Robots collaborative Robot.

Components (in this case cubes) are recognized by the 3D camera, picked up by the Kassow Robot and then transported back via a conveyor.

The overall management and organization is handled by a Rexroth ctrlX-X3 controller. Visualization and operation are done via the WebIQ Server App on an iPad.

The special feature of this picking solution is that the detection of the gripping position does not require any data from the components. This means that components unknown to the camera can also be detected and picked. These unknown components are sorted out and dropped into boxes (KLT).

H4U – Hydraulics For You – The intelligent Move

Bosch Rexroth is taking the integration capability of industrial hydraulics to the next level and transferring previously hardware-bound control functions into hardware-independent software modules. Hydraulic functions can be flexibly designed through the new H4U (Hydraulics For You) platform and directly integrated into existing automation environments. This transformation to software brings numerous advantages for end users as well as machine and system manufacturers. Hydraulic systems can be tuned in an energy-efficient way and contribute to the achievement of climate targets.

Linear Motion Technology – new possibilities for sustainable automation

From individual components to smart mechatronic subsystems – linear motion technology is provided in a variety of applications quickly and in an efficient, future-driven manner.

Discover new possibilities in automation with the help of sensorics and digitalization: The Smart Flex Effector is a sensor-based compensation module that gives robots the sensitivity of a human hand, thereby increasing automation and precision for processes with tight tolerances.

Increasing productivity, sustainability and save resources at the same time: The electromechanical cylinders guarantee long actuator lifetime and thus are economical, energy-efficient and low-maintenance.

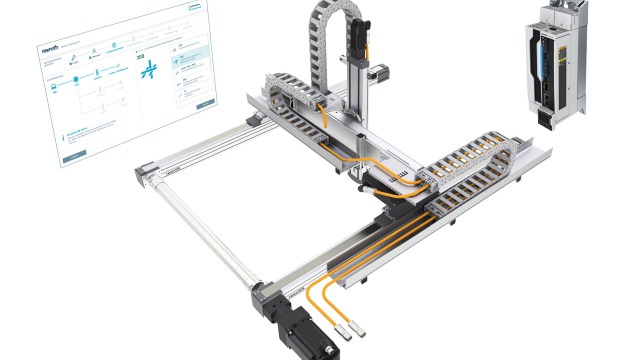

Linear axes with automation package – Automation was never as easy or convenient.

Automation made easy: Axis + drive + software in one package

Rexroth linear motion technology now makes it easier than ever before: We have packed all the components into one package, allowing you to achieve fully automated movements with single axes or actuators more quickly. With just a few clicks, a motor, drive controller, mains filter and cables can be put together and configured, software optionally included. Simply order your package using the material number given and your solution will be with you in next to no time. Everything from a single source.

Smart Function Kits – Plug & Produce with the new mechatronic subsystems

The electromechanical linear robots – consisting of our best-in-class linear technology components and the automation toolkit ctrlX AUTOMATION – can be used for diverse applications such as joining and pressing, handling or dispensing.

Modern eTools support the product selection. The pre-installed, intuitive operating software enables fast commissioning and simple graphical programming without programming knowledge. The subsystems can be easily integrated into higher-level systems through open interfaces and can be used in a wide range of applications through compatible end effectors.

Smart Flex Effector – sensor-based compensation module for robots

Revolutionize your production and reach a complete new level of automation with our Smart Flex Effector. The sensor-based compensation module with independent kinematics in six degrees of freedom gives robots and Cartesian linear systems the sensitivity of a human hand, thereby increasing precision and opening up completely new areas of application in factory automation. Processes that are difficult to control can be automated, optimized and monitored by simply retrofitting the Smart Flex Effector. Typical applications are joining processes with the marginal tolerances, complex assemblies or difficult handling tasks.