Schwäbische Werkzeugmaschinen (SW) takes high-precision workpiece machining to a new level, saving both space and costs. How? With the new TCRS temperature control option from Bosch Rexroth, which is integrated directly into the linear guide and does not require any additional components.

The BA W06 and BA W08 from SW are among the fastest machining centers on the market. They can produce high-precision aluminum alloy components, such as aircraft and vehicle parts and battery housings, in no time at all. Proven design principles, such as the monoblock, the "three-axis unit" in box-in-box design or the swiveling fixture carrier for loading and unloading in parallel with the main processing time, provide the foundation for minimum cycle times. They allow SW to increase the machine rigidity while maintaining minimal mass and reduce unproductive downtime.

The quick positioning along the three axes is achieved by highly dynamic linear motors. However, there is one negative side effect: a considerable amount of waste heat that must be removed from the machine. "An efficient heat balance is so important to us because the weight-optimized three-axis unit in box-in-box design, with thin-walled welded structures, can only absorb a small amount of heat," explains Marcus Mixner, Head of Development at SW. "Without temperature control, the dynamic power output of the linear motors would quickly lead to thermal deformations."

To continuously increase the positioning accuracy, SW has been working intensively for years on improving the thermal stability through the existing precision cooling circuit. "We view thermal accuracy as an important competitive advantage in precision machining," says Mixner. "After initial trials and optimizations with the Z-carriage, which enters the working space, we are now focusing on the temperature control of the guide in the vertical main axis, which carries the X- and Z-carriages."

The decisive solution for an implementation that is both economical and space-neutral came from the long-standing Linear Motion Technology partner Bosch Rexroth: The patented Thermo Compensating Rail System (TCRS) integrates the temperature control function as an optional feature directly into the selected roller or ball rail system. The principle is simple but effective: If the TCRS option is selected, the underside of the guide rail comes with two grooves for accommodating standard pipes, which are connected to the machine’s cooling circuit. Direct heat dissipation from the linear guide makes it easy to compensate for thermal effects, meaning that dimensional fluctuations in the process and thus the reject rate can be reduced, material can be saved, and cycle times can be further shortened.

Marcus Mixner

Head of Development at SW

Without the temperature control option, which does not require any additional installation space, the design and installation would have been much more complex, as additional components, such as cooling fins, would have been required for cooling. Since this is not the case with the integrated solution from Bosch Rexroth apart from the piping, and since no work is necessary on the machine bed, SW can realize the thermal compensation with minimum construction and operating costs. Since the TCRS guide rail has the same dimensions as the standard version, the additional design and assembly work is minimal. The installation is also as simple as usual, with Rexroth-typical features such as the clip-on cover strip saving additional time.

RSHP roller rail system with integrated temperature control function: The Thermo Compensating Rail System (TCRS) dissipates the lost heat caused by friction and the linear motors directly from the linear guide via inserted pipework. This economical solution, which does not require any additional space, enables even more precise, stable and efficient production. (Image: Bosch Rexroth)

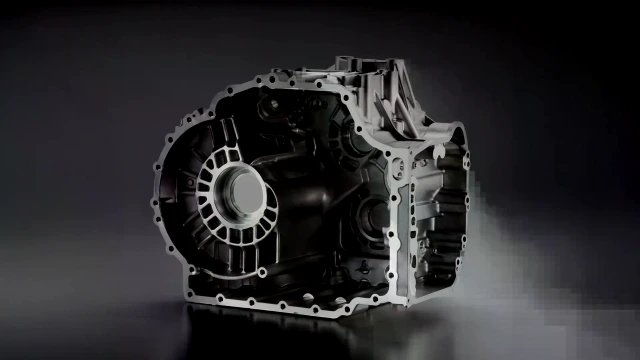

Maximum precision: Gear housing, manufactured with thermal stability on the SW BA W08 machining center. (Image source: SW)

Thanks to their clever thermal management, the two machining centers with the temperature-controlled guide rails from Bosch Rexroth achieve an exceptionally high level of precision, which is required in many application areas. Regardless of the respective workpiece and process, the integrated cooling lines dissipate the lost energy from the roller rail systems installed in the main axis. Thanks to this stabilized temperature level, the machining centers BA W06 and BA W08 achieve a remarkable positioning accuracy A (X / Y / Z) of less than 0.006 mm and a repetition accuracy R according to ISO 230-2 of less than 0.004 mm in the main axes.

Marcus Mixner also sees an important customer benefit in the faster production of good parts: "The market is increasingly demanding machines for smaller batch sizes. Therefore, we have to keep the time constants as short as possible." Thermal stability is an essential requirement for this. Based on measurement data collected over two years, SW has succeeded in developing a complex cooling water temperature control system that "cools away" the temperature peaks that occur during operation at high speeds. This allows the reject rate to be minimized throughout the entire process. "Since the market launch of the BA W06 and BA W08 machining centers, we have had nothing but positive feedback from the field," reports Mixner.

With the integrated temperature control solution, SW once again demonstrates its ability to continuously meet changing market requirements. Partnering with Bosch Rexroth has already played an important role in this respect in the past, with one example being the introduction of the RSHP roller rail system. Its runner blocks slowly transfer the rolling elements to the maximum force via a patented run-in zone, enabling low-pulsation movements. In combination with the new TCRS guide rail, SW customers will once again benefit from an increase in quality and performance.

For Mixner, the flexible temperature control option still has much potential: "We are already working on additional applications," reveals Mixner. "We also value the personal advice and expertise of Bosch Rexroth in the field of machine tools and automation." Mixner is interested, among other things, in the possibility of integrating a third function – measuring – into the guide rail in a space-neutral manner. Bosch Rexroth offers the IMS integrated measuring system for this exact purpose.

“Especially in the current market situation, innovative solutions and experienced partners such as Bosch Rexroth are vital for remaining competitive from both a technical and economical standpoint," says Mixner. "Thanks to the proven and open collaboration, we have succeeded in doubling the thermal accuracy compared to the previous machines and thereby setting new standards internationally."

Small, low cost, with high speed or high precision? With integrated measuring function or temperature control? Find the right solution for your application now!