EuroBLECH

Please request your free ticket code first at info@boschrexroth.de which you then can redeem at the red „Get Your Ticket” button. See below for more information.

EuroBLECH, 25.-28. October 2022 Hanover

Industries are facing major challenges: energy crisis, shortage of raw materials, climate change and a lack of skilled workers, to name just the most important ones. Rexroth is facing up to these challenges and offers intelligent, sustainable, safe and highly efficient solutions. In this way, machine manufacturers and end users in the forming and sheet metal working industries save valuable resources over the entire life cycle. WE MOVE. YOU WIN.

Visit us at EuroBLECH in Hanover, hall 11 booth D08

Ticket code request

With your personal ticket code, you can then conveniently redeem your ticket here free of charge.

Redeem ticket

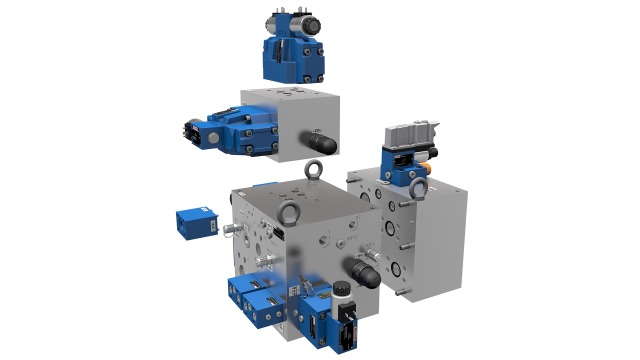

Motor pump units for faster installation

The new motor-pump unit SHP (Servohydraulic Pump Unit), based on proven product series of axial piston machines and servomotors, offers press manufacturers an innovative and compact drive element for their electrohydraulic press applications. By attaching the motor-pump unit directly to the control block, the user saves installation time because no more piping is required. At the same time, noise emissions are significantly reduced compared to conventional motor-pump assemblies with axial piston units.

Standard power units and self-contained actuators for more productivity and sustainability

The hydraulic power units CytroPac and CytroBox and the self-contained actuators CytroForce and CytroMotion set new standards in power density, energy efficiency and low-noise operation thanks to a variable-speed drive. At the same time, a flow-optimized design and additive manufactured channel geometries significantly reduce the oil volume. Less consumption for more sustainability!

Visit our Connected Hydraulics website for more information.

IH04 press modules for more safety and availability

The ready-to-use and type-tested IH04 press modules meet the requirements for installation in hydraulic presses according to ISO 16092-3 as a "safety-related component of control systems" with category 4, PLe according to ISO 13849-1. This enables constructors to design and implement upper piston functions according to general safety requirements with minimum effort. With intelligent die cushion controls from Rexroth, the IH 04 E press module for lower pistons optionally recovers energy and feeds it back into the press to reduce consumption.

Visit our Connected Hydraulics website for more information.

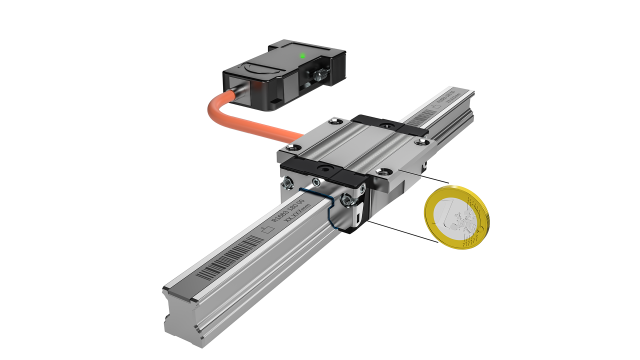

Integrated measuring system IMScompact – compact, versatile and economical

With the new IMScompact the magnetic measuring principle, the measuring sensor is fully integrated in the runner block – even with size 15 profiled rail systems. It was developed the specially for economical use in automation. There are far fewer components because there is no need for attachment parts – this saves space saves and reduces costs too. After all, measuring lengths of up to 18 meters are easily possible. When combined with linear motors, totally new automation options are created.

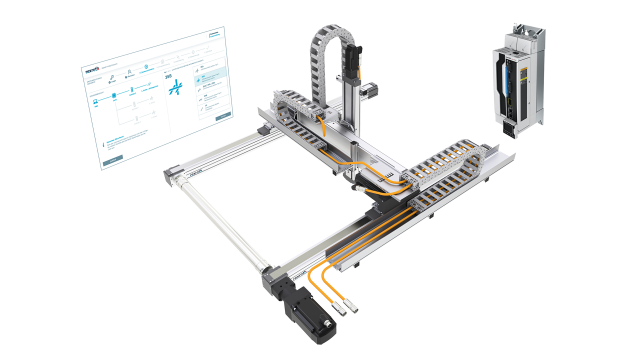

Smart Function Kits - Plug & Produce with the new mechatronic subsystems

The new linear robots - consisting of our best-in-class linear technology components, automation hardware, software and compatible end effectors are suitable for a wide range of applications in the fields of joining and pressing or handling. Modern eTools support the product selection. The pre-installed, intuitive operating software enables quick commissioning and simple graphic programming via drag and drop. The subsystems can be easily connected to the higher-level control systems through open interfaces.

CNC system MTX and automation system ctrlX AUTOMATION Powerful solution for beam cutting

Machine builders in the field of CNC lasers and plasma cutting demand significantly shorter development times and a faster time-to-market. This is possible by using the powerful CNC system MTX with ready-made project templates with powerful functions around laser cutting, such as height control, fly-cut or leapfrog. Engineering times and costs are reduced. The CNC system can be perfectly combined with components of the modular automation system ctrlX AUTOMATION. In combination with the compact and modular drive system ctrlX DRIVE, it enables space-saving dimensions and maximum scalability. For the increasingly important communication with the IoT world, it is also recommended to combine it with the control platform ctrlX CORE.

PRC7000 Weld quality to the point

Resistance spot welding technology enables high reproducibility and automation in the automotive sector, but also in the sheet metal processing industry. Welding tasks constantly present new challenges to the industry due to very complex materials as well as their combinations in conjunction with special coatings. The powerful welding control PRC7000 enables perfect welding quality. With adaptive controllers and the flexible programmability, different sheet thickness combinations as well as material mixes - from steel to aluminum - can be processed without any problems. Thanks to the integrated IoT connector, which provides structured data for central processing, quality monitoring and technology data management, PRC7000 is also ready for Industry 4.0.