K 2022

Vraag eerst uw gratis ticketcode aan op info@boschrexroth.de. Deze code kunt u vervolgens inwisselen via de rode knop Koop uw ticket. Zie hieronder voor meer informatie.

K 2022, October 19th - 26th, 2022, Hall 10, Stand B14

Sustainability in production is the overriding issue for the plastics industry. Rexroth supports machine manufacturers and users with energy-efficient drive and control solutions to make their contribution to climate protection. At the same time, digitalization increases flexibility in engineering, daily use and predictive maintenance - faster, easier, more efficient.

Let's move forward together and design sustainable solutions for plastics machinery in the factory of the future. You will find ideas at our trade show booth in Hall 10 Booth B14!

Get your ticket

With your personal ticket code, you can then conveniently redeem your ticket here free of charge.

Enter your voucher and register

Motor pump units for faster installation

The new motor-pump unit SHP (Servohydraulic Pump Unit), based on proven product series of axial piston machines and servomotors, offers manufacturers an innovative and compact drive element for their electrohydraulic applications. By attaching the motor-pump unit directly to the control block, the user saves installation time because no more piping is required. At the same time, noise emissions are significantly reduced compared to conventional motor-pump assemblies with axial piston units.

CytroForce – Push your Limits

Bosch Rexroth takes the hydraulic linear drive to a new level of development. The revolutionary solution CytroForce reduces previously space-consuming structures into a smart compact actuator. High performance values, short cycle times and low overall costs lead to a sustainable gain in productivity. Compared to non-integrated hydraulic linear actuator, only half as much installation space is required, and the energy requirement of the variable-speed drive is up to 80 percent lower. The oil quantity is also up to 97 percent lower than in open systems, which is of economic relevance.

Linear modules SMS - easy to order and quick to use

The new, ultra-compact linear modules SMS (Small Modules Screw Driven) enable highly efficient handling of small parts and perfectly round off the Bosch Rexroth linear axis portfolio. They stand for precise positioning of parts weighing just a few grams up to a maximum of 88 kilograms, are ready configured and can be selected and ordered with just a few clicks. In addition to the excellent price/performance ratio, the SMS linear modules also impress with the shortest delivery times.

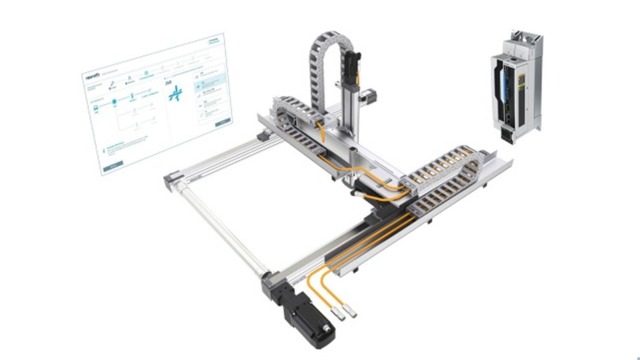

Smart Function Kits - Plug & Produce with the new mechatronic subsystems

The new linear robots - consisting of our best-in-class linear technology components, automation hardware and software - can be used for diverse automation requirements such as joining and pressing, handling, pick & place, palletizing or dispensing. Modern eTools support the product selection. The pre-installed, intuitive operating software enables fast commissioning and simple graphical programming. The subsystems can be easily integrated into higher-level systems through open interfaces. The sensor-based compensation module Smart Flex Effector is also easy to connect. This compensation element gives robots a human-like sensitivity, thus ensuring higher precision and opening up completely new areas of application in factory automation.

ctrlX AUTOMATION – Two Steps Ahead

Faster time-to-market and high flexibility are important core factors for users when deciding on an automation solution.

The automation system ctrlX AUTOMATION meets these requirements by removing the classic boundaries between machine control, IT and the Internet of Things. The Linux real-time operating system, open standards, app programming technology, web-based engineering, and comprehensive IoT connection reduce component and engineering effort by 30 to 50%.

Web-based engineering supports rapid commissioning. Graphical programming can also be used to intuitively create application programs. Technology functions for demanding processes can also be implemented quickly with application interfaces and templates.

Explore the world of hydraulics valves via app

Setting hydraulic valves manually with a multimeter and wrench? That was yesterday. Today, all you need is a mobile phone app and a Bluetooth connection to start commissioning Rexroth hydraulic components with the new digital on-board electronics, adjust them during operation and carry out diagnostic tests. This not only saves machine manufacturers time and money – for users it means greater flexibility for process changes and improved availability.

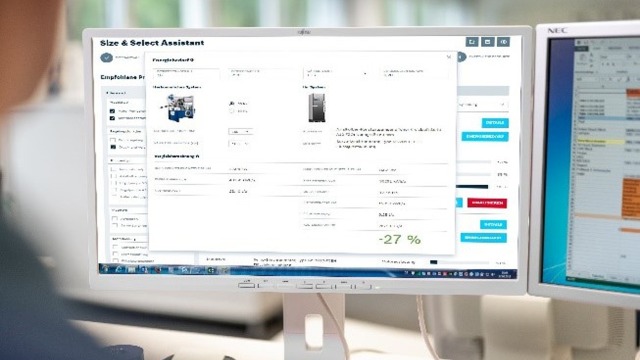

Quick and easy energy efficiency in three steps

You want to know in advance how much energy you can save in your application with intelligent and modern hydraulic drives? The Size & Select Assistant from Bosch Rexroth calculates the energy savings based on your individual machine cycle. This online tool thus simplifies and accelerates the design and configuration of the world's largest modular system for variable-speed pump drives. In just three steps, users size, configure and order their individual energy-efficient solution.