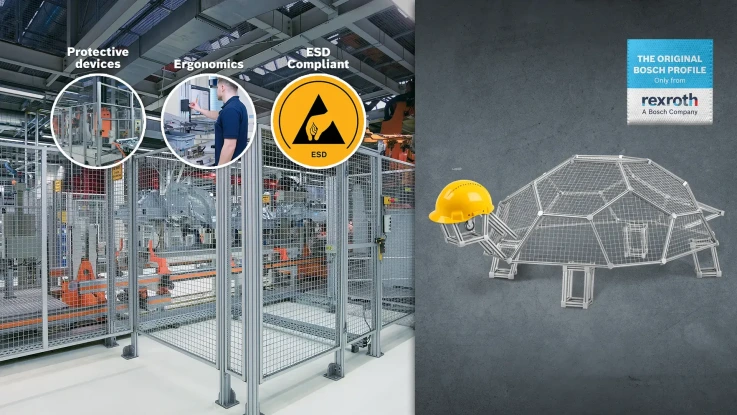

Aluminum structural framing can play a critical role in your plant safety strategy by building key structures that are designed to protect workers and equipment in your care while keeping your operations running smoothly.

FAST, EFFICIENT & FUTURE-DRIVEN

Discover a world of versatile, future-driven linear motion technology

Electrified, electronic and digitally networked solutions, combined with our superior hydraulic components and expertise, enables us to develop next-gen mobile machines together with our partners. Discover high-performance off-highway systems that deliver increased power, safety, efficiency and intelligence.

Whenever high forces are needed hydraulics is the most efficient, compact & robust technology. Our energy on demand concepts make your application energy efficient and help to reduce CO2 emissions.

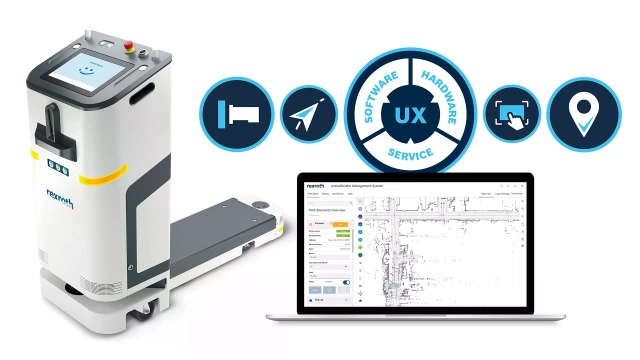

With ctrlX AUTOMATION – the Factory of the Future becomes a reality. Our new automation platform gives users the flexibility to add new automation functions via app, making automation as easy as using your smartphone.