With the Smart Function Kit for pressing and joining applications, the Italian mechanical engineering company S.EL.ME.C. has come up with a cutting-edge servo press. It not only meets the end customer’s requirements as regards press fitting and bonding during engine assembly – the Smart Function Kit also impresses with its short engineering and commissioning times and its absolute process transparency.

For nearly 40 years, the Italian mechanical engineering company S.EL.ME.C. based in Chieti (Abruzzo) has been catering to the individual requirements of a variety of sectors and has developed systems in a very short time. The degree of internal value creation is high, necessitating highly efficient system solutions with straightforward engineering and quick commissioning. Bosch Rexroth is a long-standing solution partner – the partnership between the companies dates back to the founding of S.EL.ME.C.

The servo press for an automotive plant developed by S.EL.ME.C. is based on the Smart Function Kit Pressing of Bosch Rexroth.

More efficient servo presses

When designing an electric servo press for high-speed assembly at an automotive plant in Slovakia, S.EL.ME.C. approached Bosch Rexroth. To facilitate the necessary press fitting and bonding, an electromechanical system for achieving, visualizing, assessing and storing the joining force and distance was needed. The team at S.EL.ME.C. realized that the Smart Function Kit Pressing was the ideal solution.

S.EL.ME.C.

Engineering and commissioning in record time

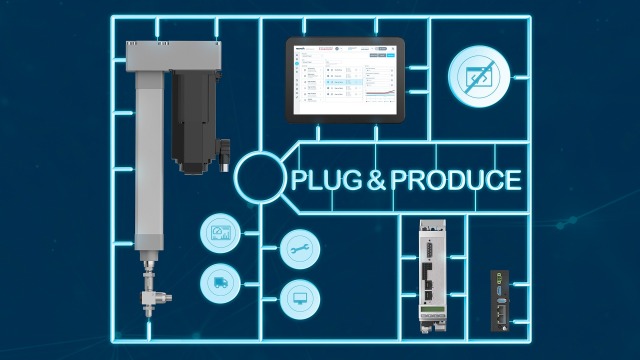

The subsystem from Bosch Rexroth combines mechanical and electrical components from Rexroth with intuitive operating software. Using modern e-tools, the mechatronic kit can be sized, configured and ordered online quickly and easily. The drive is automatically parameterized thanks to the preinstalled operating software. A software wizard provides guidance during commissioning and processes are defined via drag and drop instead of being programmed.

Robust, compact and user-friendly servo press

Although the S.EL.ME.C. project came to a halt as a result of the coronavirus pandemic, it was still completed just 12 months after kick-off. The servo press with a pressing force of up to 30 kN allows very short cycle times in the system: a new pressing cycle starts every 5.5 seconds.

Absolute process transparency and usability

Thanks to HTML5-based software, the Italian mechanical engineering company can use the user interface for the servo press on all its devices. The force/travel curves produced are evaluated on the basis of defined evaluation elements and the results are stored in an internal database. With the help of the integrated export function, the data can then be transferred efficiently for analyses and for further optimization.

Automation of the future

Industrial automation solutions impress in all respects if they meet users' needs in all product phases – from design through to after-sales service. For S.EL.ME.C., the Smart Function Kit Pressing is a complete success – and another step towards the Factory of the Future.

Experience the Smart Function Kit Pressing in a video: