Compact design, higher power, greater productivity and efficiency: With these specifications, Boschert is expanding its portfolio of press brakes to include a force range of up to 80 t. The new machine series is based around a compact, energy-efficient dual unit from Bosch Rexroth.

Press manufacturers wishing to tap into a new market segment need to offer a range of compelling features. The requirements range a design that is as compact and ergonomic as possible, to high performance and energy efficiency, right through to economic prices and total costs. Boschert, a long-established machine manufacturer, had all these aspects in mind when expanding its press brake portfolio to include a force range of up to 80 t. A key selling point for the new hybrid presses is an innovative speed-controlled dual drive from Bosch Rexroth.

The new Quick-Bend EVO press brake sets new standards in ergonomic design, dynamics, and energy efficiency (Image: Boschert).

Boschert GmbH + Co. KG from Lörrach in the Black Forest has been developing and producing machines for sheet metal processing and winding technology for almost 80 years. In addition to folding and bending presses, its product range also includes punching machines, laser and plasma machines. With the new press brakes in the Quick-Bend EVO series, Boschert offers a finely graduated portfolio with 28, 56, and 80 tons of pressing force and bending lengths of 1000, 1500, and 2000 mm.

The new press series addresses a broad market segment – from metalworking shops to industrial mass production with 24/7 operations. The manufacturer also pays particular attention to ergonomics. For example, the new presses feature an electrically height-adjustable pedal, an ergonomic armrest for seated work, and perfectly coordinated workplace lighting. Tool changing has also been simplified: As an additional option, Boschert can integrate a storage cabinet for the bending tools into the flexible machine design.

Boschert has been using compact small units with servo-hydraulic motor-pump units from its long-standing technology partner Bosch Rexroth in its hybrid presses for many years. "In addition to the outstanding project planning and coordination with Bosch Rexroth, we were also interested in the aspect of getting a complete package for the drive system, which, in addition to the electrical side with switch cabinet technology, also included the converters and motors as well as the entire hydraulics system," says Boschert Managing Director Manuel Lang on the benefits of the cooperation.

"In close cooperation with us, Bosch Rexroth has developed a drive solution for the modernization and extension of our Quick-Bend range that allows our customers to achieve higher performance and shorten cycle times on a reduced footprint," Lang goes on to explain.

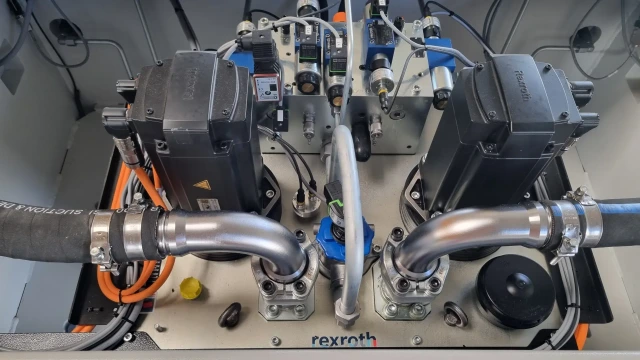

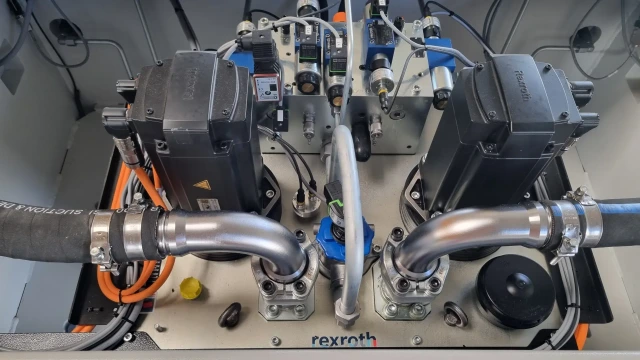

The small unit, specially designed for press brakes, supplies the two axes via two identical servo-hydraulic Sytronix drives and a common flow-optimized control block. To further optimize space utilization and costs, Bosch Rexroth also designed new suction blocks. "Compared to the previous series, we now only need one tank, one control block and fewer valves and lines," says Lang. "This enables us to meet our customers' requirements even better and offer them excellent value for money."

For Boschert, the new hybrid press drive is a breakthrough both technically and economically. By combining the two previous small units into one highly compact dual unit, the space requirement is reduced by up to 10%, depending on the model. In addition, performance has increased significantly. "The highly dynamic hybrid drive with identical flow and pressure ratios for both cylinder sides allows rapid traverse speeds of 250 mm/s," says Benjamin Kunzelmann, Head of Press Brakes at Boschert.

According to internal tests, speeds of up to 400 mm/s are even realistic. This is also made possible by the large volume flows of the latest generation of Rexroth filling valves. "For safety reasons, the working motion is limited to 10 mm/s, but can be increased to 15 mm/s if loading and unloading are done by robots," Kunzelmann adds.

Company premises of the long-established machine manufacturer Boschert in Lörrach (Image: Boschert).

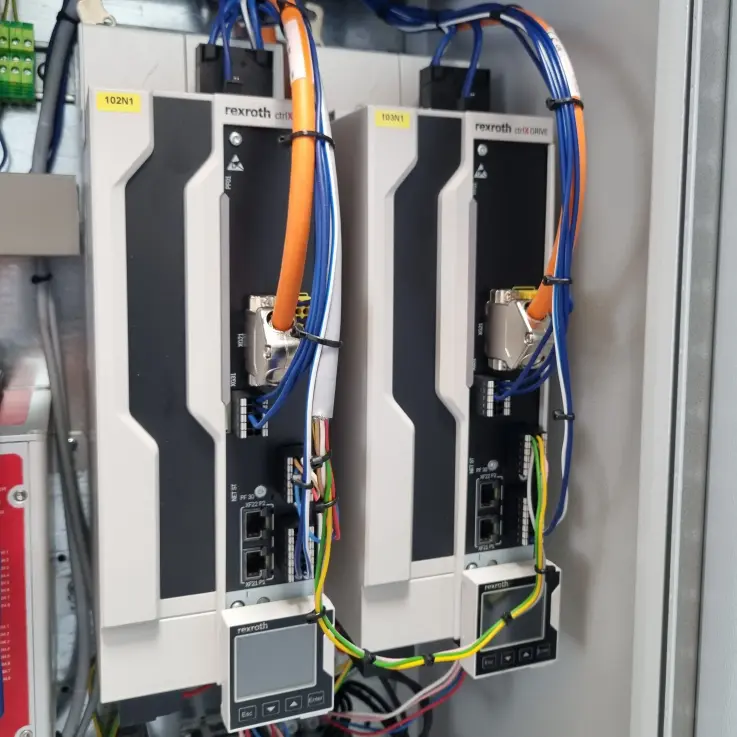

The variable-speed drive of the new dual unit uses two motor-pump units from the Rexroth Sytronix range. The combination of a 4-quadrant axial piston pump and a highly dynamic MS2N servo motor is ideal for press brakes. It is controlled with high precision by two converters from the ctrlX-DRIVE family. "With this intelligently tuned servo drive, the dual unit can optimally supply the upper piston at every operating point with minimal power consumption," explains Rexroth project manager Harald Orth. "The efficiency of the energy-saving power-on-demand principle is further enhanced by the flow-optimized control block."

According to the simulation analyses carried out by Bosch Rexroth in advance, the compact unit achieves double-digit percentage energy savings compared to a throttle control.

The new hybrid presses from Boschert use two units of the ctrlX DRIVE family from Bosch Rexroth as converters for the speed-controlled dual drive (Image: Boschert).

With the innovative ABKAG small unit from Bosch Rexroth, Boschert is ideally positioned for the market entry of its new hybrid presses in the force range up to 80 t. The compact, ergonomic, and visually appealing design, the high energy efficiency, and, not least, the attractive price are equally well received in both the trades and industry — as are the compact construction and the characteristically quiet, low-maintenance operation.

"Together with our partner Bosch Rexroth, we have succeeded in combining high press forces with groundbreaking dynamics and energy efficiency in a very small space," summarizes Lang. "Our new press brakes can compete with the fastest machines on the international market – and at the same time set new benchmarks in terms of operating costs, sustainability, and performance. This puts us in a good position in international competition."

Pump-controlled drives such as the ABKAG dual compact unit from Bosch Rexroth make press brakes and other sheet metal processing machines highly energy efficient. The power-on-demand concept provides optimum performance for every operating point and saves energy and operating costs in the double-digit percentage range compared to throttle control. At the same time, the higher control quality, dynamics, and movement precision increase productivity in manufacturing. The ecological footprint benefits from the greatly reduced need for fluids and components. In addition, ready-to-install complete units reduce the time and cost involved in development, integration, and assembly.

Author: Emre Tosun

Position: Sales Europe Middle, product area Industrial Hydraulics

Germany South

Phone: +49(711) 51046-329

Cell: +49(152) 34685476

Emre Tosun

Already connected on LinkedIn?

Emre Tosun

Bosch Rexroth AG