Compact high-performance test system for electric motors

Precise and powerful testing technology is the key to quality assurance in e-mobility. The interaction of power modules from Bosch Rexroth's IndraDrive drive technology and OPVengineering's OPVdynarig special-purpose power electronics has resulted in a successful high-speed test bench solution. This is specially designed for operating high-speed load motors with speeds of up to 30,000 revolutions per minute and clock frequencies from 10 kHz to over 20 kHz.

OPVengineering develops mechanical and automation software for highly dynamic test benches at its Karlsruhe-Durlach site. These solutions are used in the automotive industry to test drives/motors for electric mobility. The test benches are specially designed for maximum speeds and vibration excitation. Each test bench is unique and is designed and manufactured based on complex requirements. OPVengineering integrates power electronics, electric drives, sensors, hydraulic systems, heating and cooling systems, and pneumatic assemblies.

For the development of the new OPVdynarig special-purpose electronics, OPVengineering sought a solution for implementing drive technology with high power density and energy flow between test specimens on a DC-DC controller and a load drive via a common DC intermediate circuit. The goal was to create a compact system with reduced connected load. At the same time, it should be possible to use special converters for high-speed load drives with clock frequencies > 10kHz directly on the intermediate circuit.

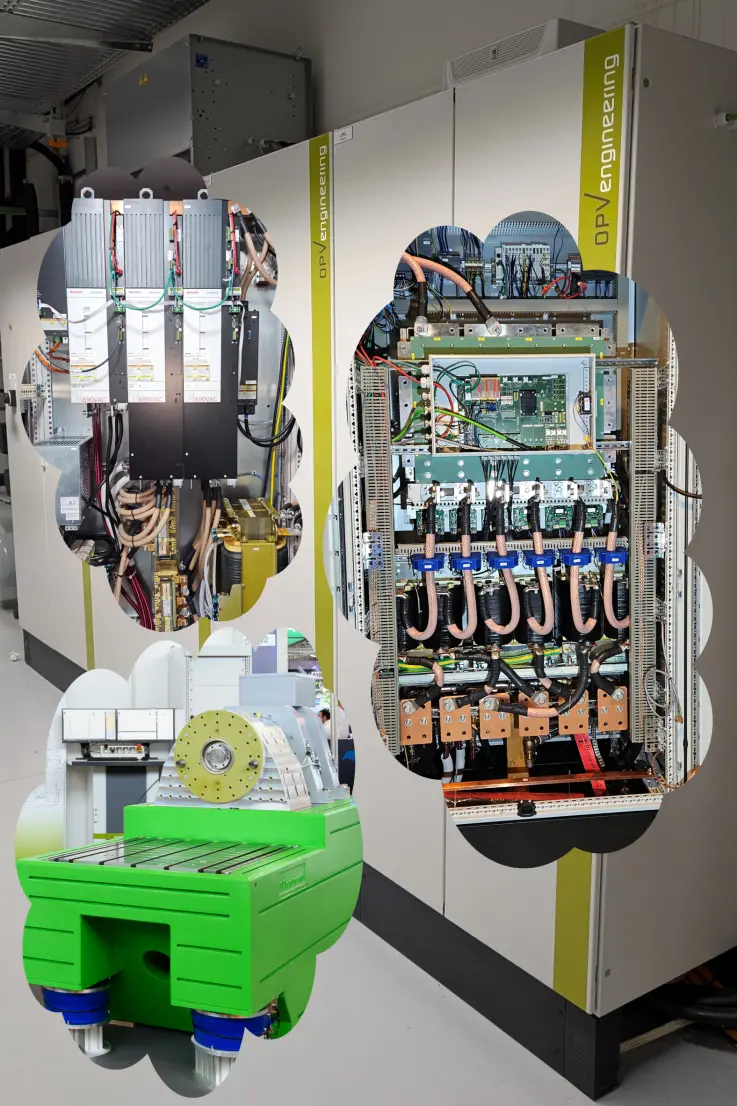

Collage of industrial control cabinets and machine parts (Image: OPVengineering).

Christian Stier, Managing Director at OPVengineering, explains: “For our high-performance test bench application, we needed to combine power supply, data communication, and control in a compact and efficient design. We therefore chose the IndraDrive HMU05 solution from Bosch Rexroth, which works perfectly with our OPVdynarig power electronics and meets all our requirements.”

The IndraDrive HMU05 is a power module from Bosch Rexroth's modular IndraDrive drive system, which is typically used in highly dynamic applications such as test benches, machine tools, or automation technology. As a supply module, it provides power for several connected drive axes. Within the solution developed by OPVengineering, the IndraDrive HMU05 acts as a grid inverter, converting the grid voltage into a DC link voltage and supplying it to the axis modules. Excess energy can be fed back into the grid, making the system particularly energy-efficient.

In the OPVdynarig solution, the IndraDrive HMU05 is combined with DC-DC converters that enable targeted voltage control between the test object and the load drive in the common intermediate circuit. This allows different operating points to be set precisely and the energy exchange to be controlled accurately—a decisive advantage for dynamic test bench applications.

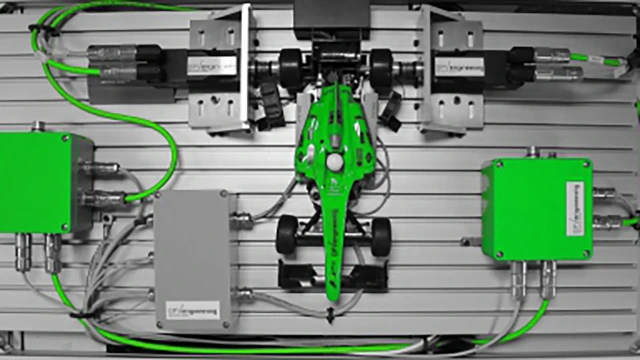

Small racing car model mounted on a test bench with sensors (Image: OPVengineering).

In the OPVdynarig solution, the IndraDrive HMU05 is combined with DC-DC converters that enable targeted voltage control between the test object and the load drive in the common intermediate circuit. This allows different operating points to be set precisely and the energy exchange to be controlled accurately—a decisive advantage for dynamic test bench applications.

The new test bench solution has a modular design and is therefore highly scalable. This makes it ideal for changing requirements. The combination of the IndraDrive HMU05 supply module, the DC-DC controllers, and the OPVdynarig power electronics enables a wide variety of test configurations to be implemented efficiently. End-to-end automation and standardized interfaces ensure rapid integration into existing test environments.

At the same time, the solution meets the highest requirements for dynamics and performance: With clock frequencies from 10 to over 20 kHz and motor speeds of up to 30,000 rpm, the latest generation of high-speed load motors can be tested under realistic conditions. These values are particularly crucial in the high-speed range, as heat generation, vibration behavior, and efficiency can only be meaningfully analyzed under extreme loads. The solution thus enables precise endurance and load testing.

The Bosch Rexroth components were implemented and put into operation within just six months. Thanks to close cooperation with Bosch Rexroth, the setup process ran smoothly and without any significant iteration loops. The high compatibility of the components used and the expert support provided during the project planning phase significantly accelerated the integration process.

“The new test bench solution enables efficient and technically high-quality testing of high-speed motors. The components from Bosch Rexroth formed the basis for the successful market launch of our new OPVdynarig special performance electronics” says Christian Stier.

With its new test bench solution, OPVengineering has succeeded in achieving maximum performance in a small space – economically, scalably, and with future-proofing in mind. The harmonious interplay between Bosch Rexroth technology and the specially developed OPVdynarig opens up new possibilities in high-speed testing technology for electromobility.

Author: David Kunkel

Telephone: +49 711 51046-223

Mobile: +49 172 8157651

David Kunkel

Already connected on LinkedIn?

David Kunkel

Bosch Rexroth AG