Verifying digital solutions early on in the simulation and using code generation to transfer them to the automation platform

As part of their digitalization efforts, many companies are introducing technologies or processes in production that are often groundbreaking for them. To minimize risks prior to commissioning and to increase efficiency – even with respect to familiar processes – simulation-based planning for systems and machines are increasingly being used, as are interlinked production workflows. MathWorks and Bosch Rexroth are bringing together simulation and automation and are thereby supporting the simplified creation of digital twins, for example.

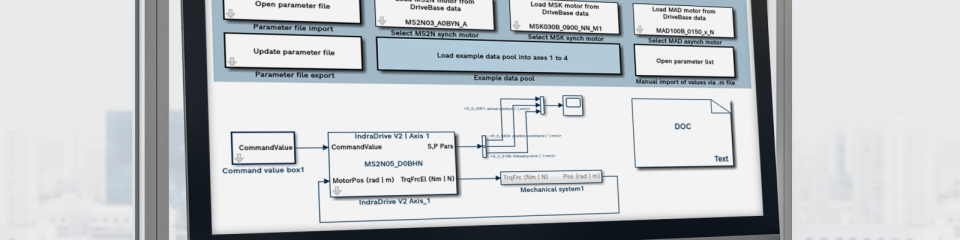

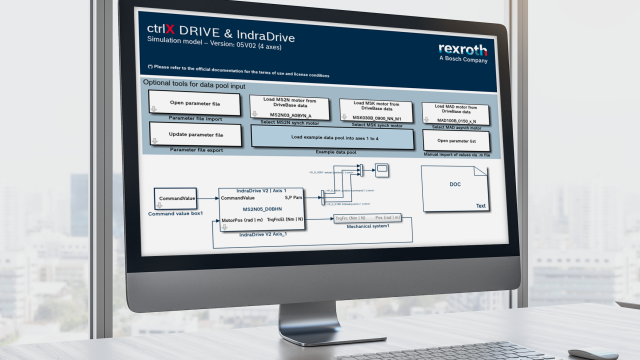

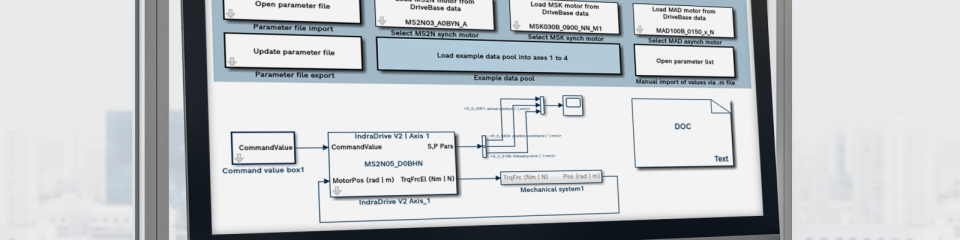

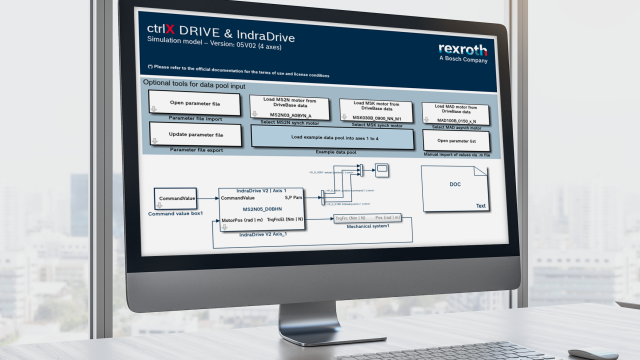

MathWorks is a developer of software for mathematical calculations that uses the MATLAB platform and the Simulink block diagram environment. MATLAB is a high-level language and interactive environment that can be used to quickly carry out calculation-intensive tasks. As software for modeling, Simulink rounds out the product. Both solutions are used in various applications, for example in machine and system engineering as well as in the development of automation components. Now they can be combined with the automation toolkit ctrlX AUTOMATION from Bosch Rexroth for the model-based development of digital solutions. To this end, interfaces were created between the solution portfolios of MathWorks and Bosch Rexroth. MathWorks is already the 50th partner of ctrlX World.

Machine models can be developed directly in MATLAB and Simulink. Via the simulation connection with ctrlX AUTOMATION, the resulting program code can be run in real time on the control platform ctrlX CORE. Model-based development enables digital solutions created in MATLAB and Simulink to be verified early on in the simulation and then to be transferred to the automation platform using code generation. Live data can also be returned to the simulation system to improve the model within the simulation.

“Thanks to the direct link between the simulation and automation platforms, users save a lot of time, because they can virtually test the machine or system in the model prior to its completion. So the digital twin of the machine comes first, before it’s set up by the machine manufacturer. Errors can thus be recognized and eliminated ahead of time, processes optimized and much more,” explained Hans Michael Krause, Head of Product Management ctrlX World at Bosch Rexroth.

“Moreover, with the joint solution, we are laying the foundation for AI-based solutions – for example in the field of predictive maintenance – in addition to enabling virtual commissioning,” added Norbert Ulshöfer, Head of the Application Engineering Team at MathWorks in Germany.

The complete solution underscores the concept of ctrlX AUTOMATION: The open automation platform with app technology and ecosystem does away with the classic borders between machine control, IT and the Internet of Things and, in doing so, shines a spotlight on co-creation.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, more than 31,000 associates generated sales revenue of around 6.2 billion euros in 2021.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,600 associates worldwide (as of December 31, 2021). The company generated sales of 78.7 billion euros in 2021. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 76,100 associates in research and development, of which more than 38,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de