Robotics and automation components simplify and speed up the development and commissioning of automated guided vehicle systems

Bosch Rexroth enables the individual and straightforward automation of all logistics tasks for the entire value stream of inbound, outbound and intralogistics. Modular building blocks offer the selection of individual automation components or even entire system solutions and cover individual requirements in a scaled manner. Fully open standards for communication, low/no-coding programming and intuitive operator interfaces make it easier to integrate the systems into a variety of applications.

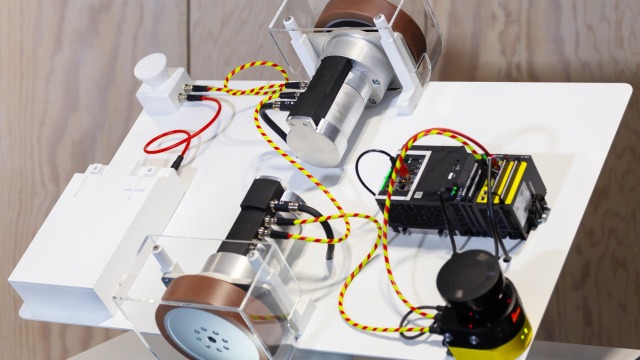

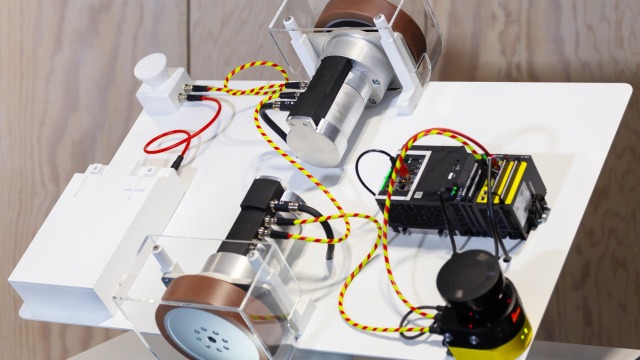

With the ROKIT robotics kit, Bosch Rexroth provides flexible, modular solutions. Manufacturers of automated guided vehicles and autonomous mobile robots (AMR) as well as system integration companies can easily implement and quickly develop their know-how. The robotics kit includes software and hardware components for a wide range of mobile vehicle architectures. As an open system solution, the modules fit seamlessly into higher-level control systems. The ROKIT Locator localization software determines the vehicle position in real time and automatically produces maps of the surroundings, without the need for any structural measures. In combination with the automation toolkit ctrlX AUTOMATION, users can combine on the control platform ctrlX CORE all robotics tasks which were previously spread across PCs, PLCs and safety control systems. This reduces not only the number of components but also the space required.

ctrlX AUTOMATION: Open automation toolkit for logistics

The automation toolkit ctrlX AUTOMATION relies on open standards such as EtherCAT, OPC UA or MQTT throughout. The ctrlX Data Layer ensures rapid, trouble-free data exchange between process and safety functions. ctrlX CORE is based on a Linux operating system and app technology. Developers can select from numerous Bosch Rexroth apps, make use of third-party apps or create their own. Even after delivery, updates or additional apps can be installed both quickly and easily.

For the new COMPACT SHUTTLE, DAMBACH Lagersysteme relies on the space-saving and powerful control system ctrlX CORE from the ctrlX AUTOMATION portfolio. The shuttle makes it possible to store and retrieve large load carriers, e.g. EUR pallets, in high-bay warehouse channels. DAMBACH opted for ctrlX AUTOMATION in light of its compact design and high performance.

VDA 5050 for operating mixed fleets

The ACTIVE Shuttle autonomous mobile robot from Bosch Rexroth communicates with the master controller via the standardized VDA 5050 interface. This interface, which is defined across manufacturers, is the result of a collaboration between the German Association of the Automotive Industry (VDA) and the VDMA’s Materials Handling and Intralogistics group. It makes it easier to operate mixed fleets with tractors, forklift trucks or AMRs and avoids interoperability problems during day-to-day operations. As a Plug and Go solution, the robust ACTIVE Shuttle automates cyclical transport tasks as well as the needs-based supply of materials. The comprehensive safety concept meets Performance Level d requirements in accordance with EN ISO 13849-1.

Flexible robotics and smart mechatronics

Intelligent Pick and Place solutions such as Smart Item Picking from Bosch Rexroth are used to sort, pack or transfer materials within goods and value streams. The software for commercially available industrial robots recognizes a large number of objects to be gripped model-free and without teaching. It also combines high pick rates with significantly reduced error rates. Collaborative 7-axis cobots from Kassow Robots automate handling tasks in extremely tight spaces and offer high flexibility with their seven axes. Along packaging, logistics and storage lines, the modular linear motion technology toolkit opens up individual solutions – from single components to smart mechatronic subsystems. Plug and Produce linear robots combine best-in-class linear motion technology components, automation hardware and software. With the help of the LinSelect selection tool and the online configurator, users can put together a suitable system with just a few clicks.

Intelligent and safe functions for forklift trucks and other machines

The BODAS ecosystem for larger logistics vehicles links together all software and electronic hardware such as sensors, displays and control devices for comprehensive applications such as IoT telematics. BODAS is open, scalable and offers easy access to free up resources and increase profitability.

Bosch multi-camera system for forklifts now available as retrofit solution

The use of forklifts in everyday work is associated with a variety of accident risks. Collisions are usually caused by a lack of visibility of the vehicle surroundings. This is where the Bosch sight assist, which is based on the multi-camera system, provides valuable support. It generates a 360° representation of the current vehicle surroundings and displays it on a monitor in the cockpit. The driver can thus clearly see what is happening in the vehicle’s vicinity at all times. A new version of the multi-camera system is from summer 2023 through a network of selected, specially trained distribution partners also available for retrofitting. The retrofit multi-camera system comprises four compact near-range cameras (including control unit), a universal wiring harness, a 10-inch touch display, and a set of camera mounts. The complete package thus includes everything needed for quick and simple installation, regardless of the vehicle make, model, or year of manufacture.

Automation software for service robots

The automation of service robots can be easily and efficiently implemented by Bosch with a modular software platform. As an engineering partner, Bosch Engineering accompanies machine manufacturers, who can thus concentrate on their core development work, namely putting in place specific robotic functions for the particular application. localization, obstacle detection and travel path calculation (navigation), offers all the functionalities for complete robot automation.

Driverless maneuvering of new vehicles in car plants

Automated Vehicle Maneuvering is based on Bosch Automated Valet Parking technology. The infrastructure installed at the car manufacturer's plant consists of lidar sensors and, depending on the requirements, additional Bosch stereo cameras. The information generated by sensor technology comes together on edge computers and smart algorithms transmit the route to be taken. This is how Bosch makes driverless maneuvering of the cars possible, even in tight spaces. Thanks to the smart technology in the plant, the technical requirements in the vehicle itself are minimal. The driverless maneuvering service can be used in various ways. For example, the system can maneuver new vehicles from the end of the production line to the loading station. In the future, Bosch's new solution will allow vehicles to be maneuvered between free parking spaces and charging stations, thus enabling automated overnight charging, for example. The benefits are obvious: Automated Vehicle Maneuvering increases efficiency while reducing downtime and costs.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries more than 32,000 associates generated sales revenue of around 7.0 billion euros in 2022.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 420,000 associates worldwide (as of December 31, 2022). According to preliminary figures, the company generated sales of 88.4 billion euros in 2022. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 85,000 associates in research and development, of which nearly 44,000 are software engineers.