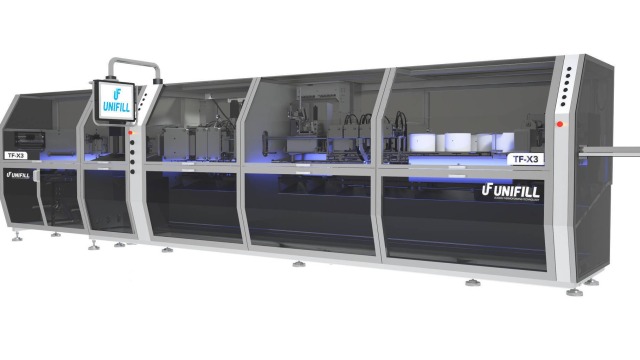

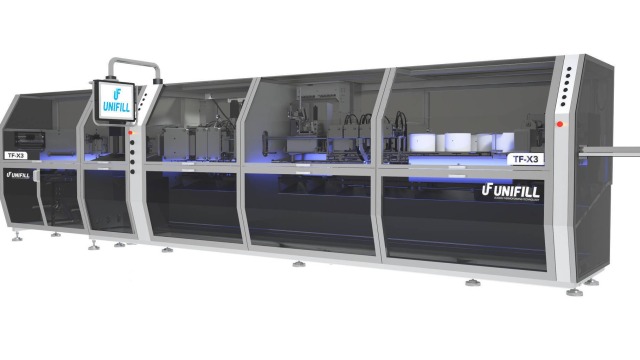

With the TF-X series, UNIFILL Srl will present its new generation of thermoforming machines at interpack 2023. Several new developments from UNIFILL combined with control cabinet-free drive technology from Bosch Rexroth result in a modular machine concept with new functionalities that can be flexibly adapted to customer-specific requirements.

With the X-Generation, UNIFILL has developed a new machine concept for its thermoforming technology. The machine, with up to 35 cycles per minute, is suitable for filling liquid and semi-dense products in single-dose packages for the food and non-food industries. Scalable solutions from Bosch Rexroth reduce control cabinet size and wiring effort. The IndraDrive Mi control cabinet-free drive technology meets the high performance required in the production of squeezable, peelable, stand-up, contour shaped and strip packs and supports the precision and flexibility of the new machine type.

New functionalities

With this machine generation, UNIFILL also offers new technology options: Data processing, predictive and preventive maintenance, and a new HMI interface simplify the interaction between operators and the machine. Based on solutions from Bosch Rexroth's automation toolkit ctrlX AUTOMATION, it also opens up a high degree of flexibility. It is based on the latest app technology: Via the ctrlX Store, users can obtain apps from Bosch Rexroth or apps from third-party providers, or create apps themselves. For example, IoT functionalities or options requested by end users can be installed. Machines can be scaled and customized on this basis. An OPC UA interface enables a secure connection of the machine to the entire plant.

Exploiting synergies

Thanks to UNIFILL's investment in research and development and Bosch Rexroth's support, the TF-X series is equipped with future-oriented functionalities. Synergies quickly emerged as part of the collaboration. As a result, the ambitious goals were quickly achieved.

Increasing sustainability

Sustainability and environmental compatibility have become a constant focus for UNIFILL. More and more functions for saving energy are also being integrated into automation components. Bosch Rexroth offers solutions for energy monitoring as well as functions for increasing energy efficiency. For example, the control platform ctrlx CORE of the automation toolkit ctrlX AUTOMATION makes it possible to collect and evaluate information from all machine components. Intuitive dashboards immediately display processed data and statistics.

In addition to classic paper solutions, UNIFILL would also like to use recyclable materials with a single polymer such as mono-PE, PET or PP. This helps to save resources.

UNIFILL at interpack 2023: Hall 15, Booth B42

Bosch Rexroth at interpack 2023: Hall 6, Booth A42

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries more than 32,000 associates generated sales revenue of around 7.0 billion euros in 2022.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 421,000 associates worldwide (as of December 31, 2022). The company generated sales of 88.2 billion euros in 2022. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 136 locations across the globe, Bosch employs some 85,500 associates in research and development, of which nearly 44,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de