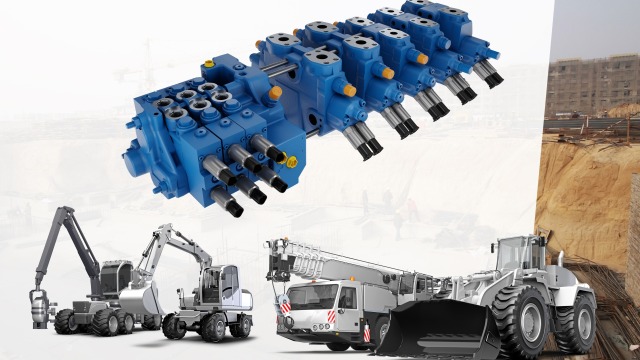

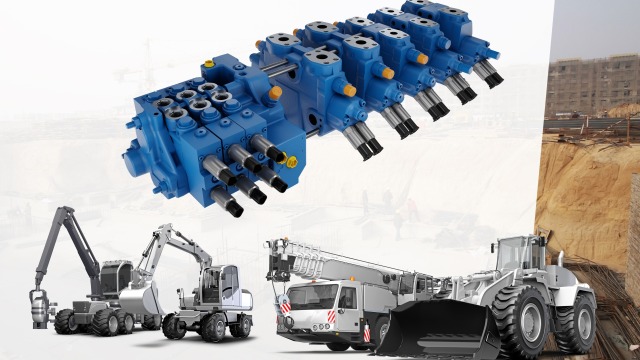

Thanks to the modular and scalable valve platform, off-highway manufacturers can enjoy greater flexibility and agility even with small quantities

Bosch Rexroth is expanding the adaptable and scalable valve platform RS LARGE with new modules for larger machine classes. The new flow sharing modules, which start at frame size 22, are optimized for electro-hydraulic control and are fully prepared for driver assistance functions. Manufacturers of large construction machinery, material handling equipment or forestry vehicles benefit from a flexible machine design with standardization effects as well as greater energy efficiency and simple digitalization. The valve platform is also suitable for mobile cranes, large lift trucks, bulldozers and industrial excavators for recycling and similar applications.

The RS LARGE valve sections of sizes 15, 20 and 22 enable highly flexible assembly of hydraulic control blocks for off-highway vehicles from individual modules. Moreover, with consumer flow rates of up to 400 l/min, the modular control blocks are optimized with regard to their space requirement, weight, performance and energy efficiency. The valve sections in size 22 are new to the RS portfolio, while additional modules in size 25 and higher are also in preparation.

Maximum agility with online configurator

With the RS LARGE online configurator, machine manufacturers can quickly and easily create their very own valve configurations. The corresponding circuit diagrams as well as the 2D and 3D installation models are generated automatically and made available for download. This delivers significant time savings in engineering since users can check the positioning of the control block in the machine at an early stage and make any necessary adjustments. Upon order submission, all technical documents are transferred directly to Bosch Rexroth production planning. This ensures shorter delivery times, particularly for the construction of prototypes or small series.

Increased flexibility

With its modular approach, the Rexroth flow sharing platform (RS) provides off-highway manufacturers with a flexible and efficient means of creating customer-specific machine concepts in a single or dual-circuit system. By combining post- and pre-compensated valve sections, such customer-specific concepts exploit the full benefits of the flow sharing approach and benefit from its ability to distribute flow in a pump saturation state across all consumers when under peak load. This avoids an abrupt and potentially dangerous breakdown in the motion of a function in the case of flow saturation. At the same time, the platform allows specific functions to be prioritized – for example, a slew drive or an attachment. Additional function modules can be integrated to minimize assembly and piping requirements as well as to reduce the overall complexity. Examples include the RSM20 stabilizing module for wheeled loaders, an anti-drift valve (ADV) or the RBM15 steering priority module.

Greater energy efficiency thanks to (dual-circuit) flow sharing

The RS valve platform strikes an ideal compromise between reduced pressure loss, accurate control and a modular hydraulic architecture, thereby creating optimum conditions for maximizing the overall efficiency of mobile working machines. The dual-circuit element enables intelligent connection or disconnection of the two hydraulic circuits, which boosts energy efficiency by at least ten percent. Regeneration functions for further efficiency gains can be integrated directly into the valve sections, while the tank preload can be adapted electro-hydraulically to the actual operating conditions.

Prepared for driver assistance functions

The electro-hydraulic control of the platform via software unlocks further potential for reducing energy use and raising efficiency. In combination with the modules of the electronic Open Circuit (eOC) solution portfolio, driving and working functions, for example, can be included in a shared hydraulic circuit. This also facilitates the integration of driver assistance functions, such as following specific trajectories or stopping vehicle movement upon departure of the working area. To this end, Bosch Rexroth offers a range of prepared software modules, which can be easily adapted to individual requirements.

Robust design for high-pressure applications

All RS valve sections are designed for consumer pressures of up to 420 bar and can be equipped with pressure relief valves with manual or electric-proportional adjustment. The pump port in the inlet element supports pressures of up to 400 bar as well as primary pressure relief. Additionally, the inlet features LS unloading along with an optional unloading valve to prevent pressure peaks and ensure that movements start dynamically.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, more than 31,000 associates generated sales revenue of around 6.2 billion euros in 2021.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,600 associates worldwide (as of December 31, 2021). The company generated sales of 78.7 billion euros in 2021. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 76,100 associates in research and development, of which more than 38,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de