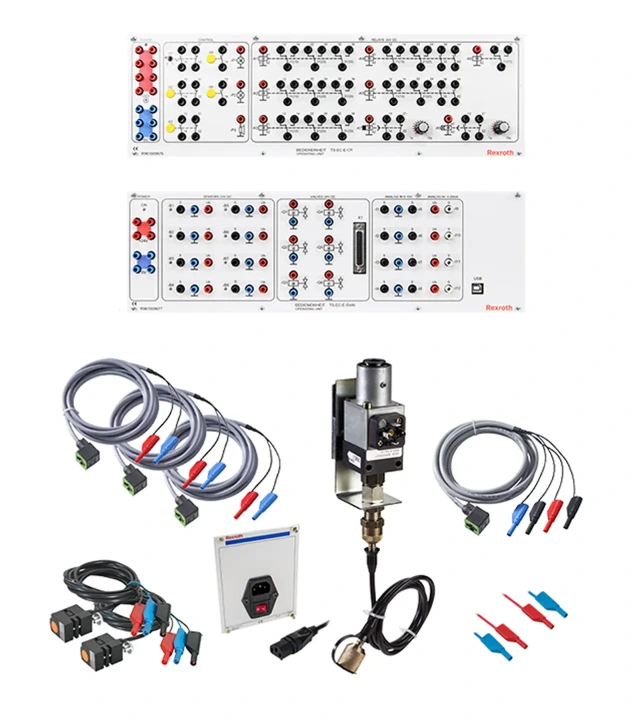

Immerse yourself in the world of hydraulic training systems from Bosch Rexroth – tailored to the requirements of industry and educational institutions. Our modular teaching systems provide everything you need for effective and practice-oriented education and training of hydraulics specialists: Workstations, device sets, and exercises that are perfectly tailored to your learning topic.

Experience learning topics in a practical way

For each learning topic, we provide you with device sets that enable practical exercises and make theoretical knowledge tangible. With our extension device sets, you can upgrade from one learning topic to the next and flexibly supplement your equipment. This makes learning not only efficient, but also exciting and modular!

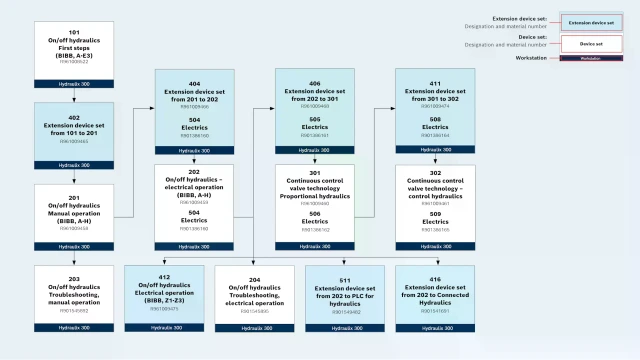

Learning topics – Industrial hydraulics: Hydraulix 300

Gain an overview of the device sets for the Hydraulix 300 workstation and explore your learning topic with just one click:

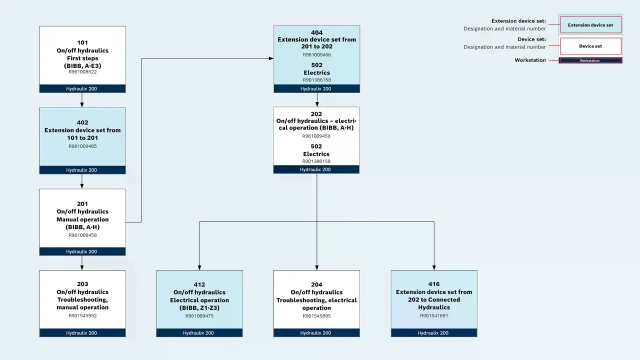

Learning topics – Industrial hydraulics: Hydraulix 200

Gain an overview of the device sets for the Hydraulix 200 workstation and explore your learning topic with just one click:

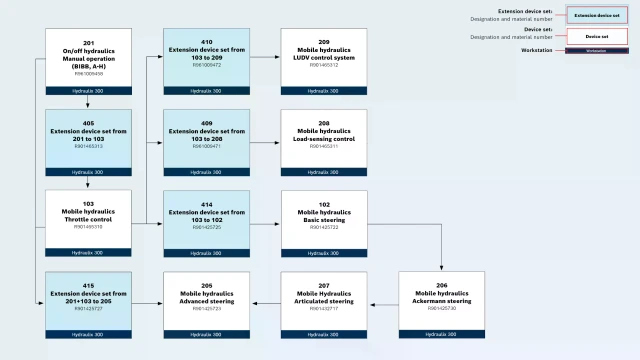

Learning topics – Mobile hydraulics: Hydraulix 300

Gain an overview of the device sets for the Hydraulix 300 workstation and explore your learning topic with just one click: