At Agritechnica 2025, Bosch Rexroth will present scalable digital solution modules for future-proof agricultural machinery

Given the increasing demands for precision, efficiency, and user-friendliness in agricultural machinery, the complexity of their development is growing. Bosch Rexroth specifically supports manufacturers in the further development of their vehicles. At Agritechnica 2025, the company will present a wide range of new hardware and software modules that drive automation, electrification, and connectivity, and increase efficiency. This scalable, technology-agnostic approach enables OEMs to quickly and precisely equip machines of various sizes and drive types with pioneering driving, assistance, and working functions, and to successfully position themselves in the market.

With Bosch Rexroth as a strategic technology partner for agricultural machinery, manufacturers can optimize the development cycle of their vehicles and intensely dedicate themselves to machine-specific functionality and driving characteristics. Scalable solution modules free OEMs from time-consuming groundwork, for instance, to make agricultural equipment more powerful, ensure its functional safety, and promote intuitive operation. This approach also contributes to reducing financial risks, as the provided modules already comply with all relevant standards and legal regulations.

Efficient development processes in agricultural engineering

An example of simplification in engineering are validated software modules that can be modified by the machine manufacturer within the framework of the "Try it First" concept. The new BODAS Studio development environment, based on a standardized, open software architecture with various integration options such as MATLAB and Simulink from MathWorks, also saves time in code generation. Both newcomers and experienced experts receive qualified answers to their development questions via the myBODAS collaboration platform. myBODAS also offers a comprehensive knowledge database with an AI-powered search function and free access to the BODAS software modules.

Telematics innovations include Over-The-Air services (OTA) for fleet updates, whereby the BODAS Connect Universal Flasher module can also be used to update third-party control units in mixed E/E environments via the UDS (Unified Diagnostic Services) protocol. For this purpose, Bosch Rexroth and Trackunit have formed a strategic partnership to combine the OTA expertise of BODAS Connect with the Trackunit ecosystem. This cooperation dynamically extends the functionality of agricultural machinery, simplifies service through Over-the-Air (OTA) updates, and simultaneously increases user-friendliness and operational efficiency. As a holistic technology partner, Bosch Rexroth places particular emphasis on compliance with legal safety and security requirements for BODAS, including new EU directives such as Machinery Regulation 2023 and the Cyber Resilience Act.

Safety and Productivity through Automation

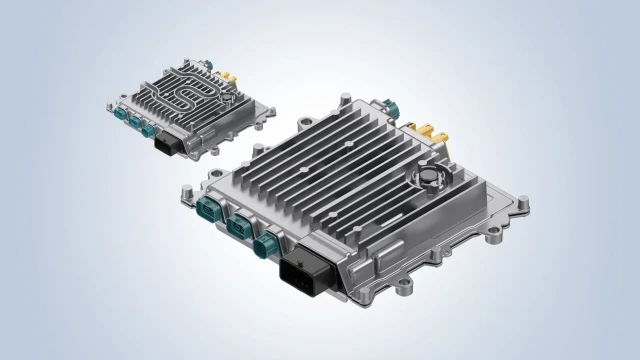

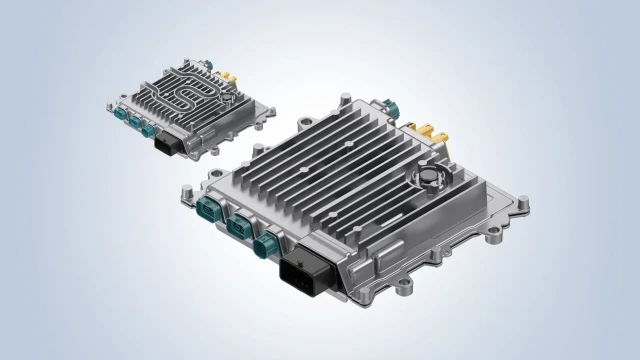

Increased safety and productivity in agricultural technology, even with less experienced operating personnel, are enabled by partially automated functions and advanced assistance systems. Bosch Rexroth creates the system prerequisites for their introduction. The new High Performance Computer Offroad Robotic Controller ORC2 paves the way for autonomous and complex driving and working functions. The BODAS ecosystem already includes the Collision Avoidance System CAS based on sensors for environment detection. In addition, the Kinematic Position Sensing KPS reports the exact position of actuators, for example, on tractor front loaders.

Modular Portfolio for the Electrification of Agricultural Machinery

The electrification of agricultural machinery is significantly simplified and accelerated by standardized and scalable software modules from Bosch Rexroth, which cover all voltage ranges from 96 volts up to the high-voltage range. This saves OEMs the costly development of their own control electronics. The eLION software portfolio includes the application software Electric power control EPC for power management, EDA for the traction drive, and Pump drive control PDC for the efficient execution of working functions. Hardware such as the new Rexroth high-voltage motor series EMP1, which offers up to 50% higher power density for agricultural machinery within the same installation space, complements the portfolio.

New Developments in Hydraulics

The new, compact radial piston motor MPR Performance from Bosch Rexroth offers greater flexibility in the design of agricultural machinery and increases its productivity and energy efficiency. Compared to its predecessor, the MCR3, the patented motor design reduces components by 25% and overall length by up to 30%, offering advantages in machine center of gravity, installation space, and ease of installation. An up to 9% higher start-up efficiency, optional 470 bar nominal pressure, and an approximately 25% higher maximum speed also contribute to lower system and total operating costs.

With the next generation of hydraulic systems, Bosch Rexroth makes available new degrees of freedom with Electronic load sensing ELS, through electronic Open Circuit (eOC) variable piston pumps for the flexible adaptation of hydraulic performance to the requirements of various implements. The advantage for the end-user: simplified operation, highly automated workflows with consistent or even better quality, and higher productivity with improved energy efficiency.

Together with its subsidiary HydraForce, Bosch Rexroth will also present a comprehensive portfolio of modular and compact hydraulic solutions at Agritechnica. Product highlights include the compact and precise directional valves EDG-OBE and EDH-OBE, which can be flexibly used for small installation spaces up to high flow rates. The innovative TS90-G34L valve increases the efficiency of powershift transmissions with multiple clutches. The HF-Impulse 2.0 software platform simplifies the development and configuration of ExDR controllers.

Bosch Rexroth at Agritechnica 2025: Hall 16, Booth A05

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, around 32,600 associates generated sales revenue of 6.5 billion euros in 2024.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 418,000 associates worldwide (as of December 31, 2024). The company generated sales of 90.3 billion euros in 2024. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 490 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 87,000 associates in research and development.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de