With the EDG-OBE closed-loop piloting module with integrated onboard electronics, Bosch Rexroth is economically unlocking the benefits of digitalization while increasing the efficiency of hydraulics. The integration of digital technologies including sensors, actuators, and intelligent control systems increases the precision and responsiveness of hydraulic systems. Manufacturers benefit from fast response times and high system reliability.

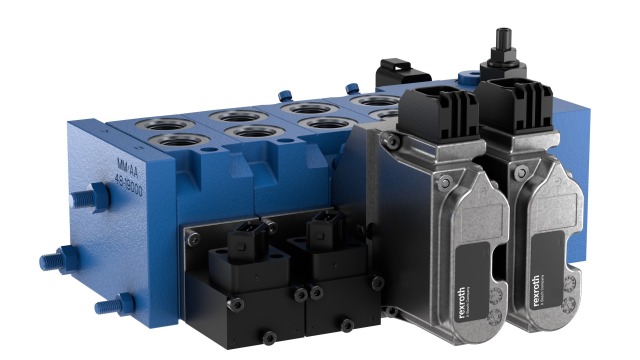

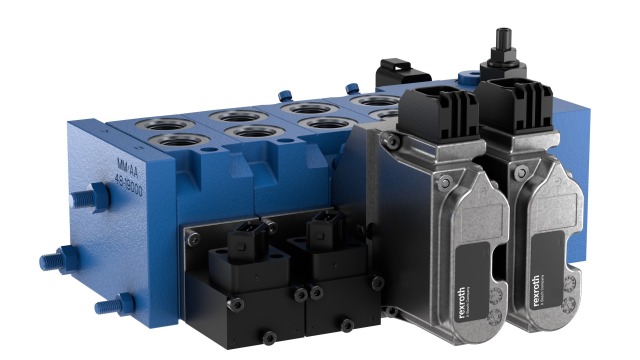

The piloting module with integrated onboard electronics has been developed for the EDG range of pre-compensated compact directional valves. The EDG-OBE complements the existing EDG-DP direct-operated and EDG-PP pilot-operated analog open-loop products. As per the whole EDG range, this solution offers the possibility to integrate auxiliary functions such as anti-shock, anti-cavitation or LS relief. This increases the flexibility and configurability of the product family.

The EDG-OBE features closed-loop operation with integrated hall-effect spool position feedback, enabling the onboard controller to continuously adjust piloting signals to maintain the desired spool position. The high accuracy opens up new options for various precision applications, including autonomous vehicle functions.

The EDG-OBE is a plug-and-play CAN control compatible with CAN SAE J1939, a vehicle standard based on the CAN BUS automotive protocol widely used in mobile machine applications. Acting as an independent CAN device on the network, the main vehicle control only needs to send a command instructing the valve to open at a specific percentage of its maximum capacity. The onboard electronics implements the command. It can also report back information on status, opening position, and diagnostic messages to the vehicle controller.

The onboard electronics handles all the functions required to provide a stable output of the valve. It operates the PID (Proportional-Integral-Derivative) control loop, performs curve shaping and scaling if configured, and controls the piloting of the main spool by adjusting signals multiple times per second to maintain the set position.

Using the CAN-based distributed control architecture not only enhances efficiency but also lightens the load on the main vehicle controller, allowing machine designers to use a more optimized main vehicle control with fewer total inputs and outputs. For example, a truck-mounted crane may use both a vehicle-mounted control station and a remote "belly box". An aerial work platform typically employs ground controls as well as platform controls. These separate control stations can operate the valves independently. The long wire loom to the platform only needs to carry a CAN signal, eliminating the need for heavy current-carrying conductors associated with significant voltage drop. Redundant controls can also be implemented for safety-relevant applications.

By closing the loop with spool position feedback, the EDG-OBE compensates for variations in coil resistance, temperature, and hydrodynamic forces. Even manufacturing variations are overcome with position feedback. The result is accuracy comparable to servo-controls, fast response times, and minimal hysteresis.

Bosch Rexroth at Agritechnica: Hall 16, Booth A08.

Media Assets

Basic Information Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile and Industrial Applications as well as Factory Automation. With its intelligent components, customized system solutions, engineering and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries more than 32,000 associates generated sales revenue of around 7.0 billion euros in 2022.

Basic Information Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 421,000 associates worldwide (as of December 31, 2022). The company generated sales of 88.2 billion euros in 2022. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 136 locations across the globe, Bosch employs some 85,500 associates in research and development, of which nearly 44,000 are software engineers.

Press Contact

Spokesperson technology topics

Manuela Kessler

+49 9352 18-4145

Manuela.Kessler@boschrexroth.de