Focus products:

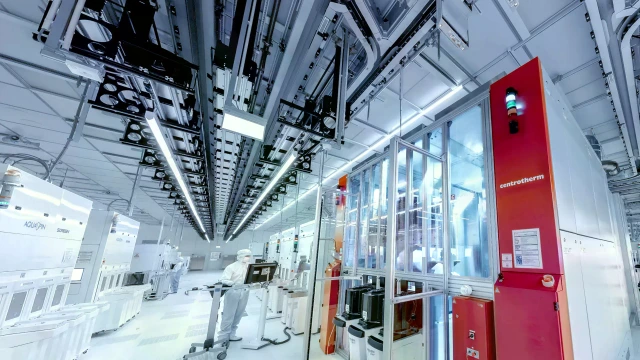

Accelerate semiconductor engineering and automation

Welcome to your experienced engineering and automation partner for mechatronics and motion control. We support you with high-speed engineering and ready-to-use solutions throughout the entire semiconductor and electronics value stream.

A 20+years track record combined with fast responsiveness

Gain speed from the lab to the fab – with close collaboration from the first prototype. Unlock simplicity with ready-to-use mechatronic subassemblies and precision motion control designed for your application. All of them fit easily and seamlessly into your machine design. Master scalability with copy-exact manufacturing. Leverage sustainability and longevity with our in-house quality components. And for any support, our expert engineering teams are always close to you.

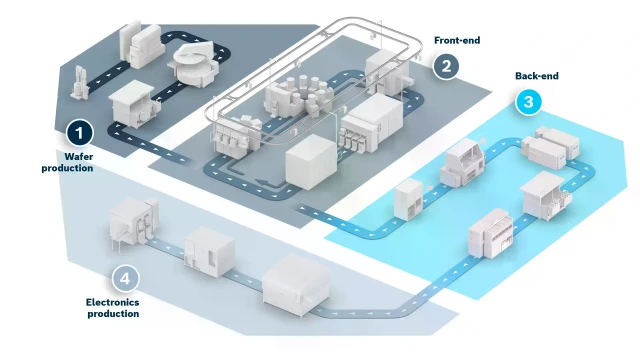

Front-End

Wafer Transport OHT

YOUR VALUE STREAM NEEDS ...

- Frame structure

- Load capacity

- Interface to OHT

- Safety & cleanroom considerations

Product Category:

COMPONENTS

Cleanroom aluminum strut profiles and connecting elements

BENEFITS

- Anodized aluminum to reduce particle generation

- Cover open T-slots with slot covers for cleanroom compliance

- Compatibility with ISO Class 3–4 environments

-

Mounting brackets and fasteners

(M8 stainless or stronger) resist vibration

Wafer Cleaning – Wafer Handling System for Wafer Batch Cleaning

YOUR VALUE STREAM NEEDS ...

- Splash-free wafer movement

- Minimized particle contamination

Product Category:

SUB-ASSEMBLY

Batch Wafer Handling:

Seamless, precise transport of wafer boats through every stage of the wet cleaning process

BENEFITS

-

Precision Engineering

Multi-axis motion control and jerk-limited lift-outs enable highly accurate wafer handling. Ensures repeatable, smooth movement for minimal mechanical stress. -

High Throughput & Efficiency

Optimized for continuous, fast wafer transfers without compromising safety or precision. Boosts productivity while maintaining consistent process quality. -

Gentle & Splash-Free Handling

Designed to minimize mechanical and chemical stress on wafers. Ensures integrity of sensitive wafer surfaces during wet processing.

Wafer Cleaning – Wafer Handling System for Single Wafer Cleaning

YOUR VALUE STREAM NEEDS ...

- Compatibility with all major CMP and metrology platforms

- SEMI E84/E87 compliance

Product Category:

SUB-ASSEMBLY

Single Wafer Handling:

High-precision wafer transport solution for the single wafer cleaning between CMP & downstream process

BENEFITS

-

High-Precision Transport

Ensures accurate and stable wafer movement between CMP and downstream processes. Minimizes wafer misalignment and handling errors. -

Seamless CMP Integration

Designed specifically for transfer between CMP equipment and subsequent cleaning or processing stations. -

High Throughput & Efficiency

Optimized for rapid wafer transport without compromising precision. Enhances overall process yield and production efficiency.

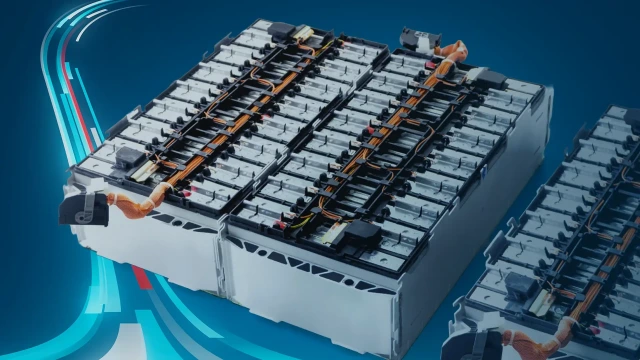

Deposition

YOUR VALUE STREAM NEEDS ...

-

Cleanliness and contamination control:

ISO 5 clean room at minimum. No lubricants that outgas or create particles – often dry bearings or vacuum-compatible greases -

Temperature and material compatibility:

Tolerance of process temperatures (up to ~450 °C for CVD, higher for some PVD) without deformation

Product Category:

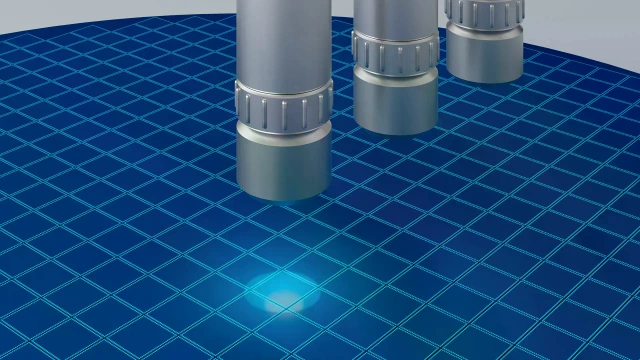

SUB-ASSEMBLY

Wafer Pin Lift:

Our wafer handling system for deposition guarantees accurate lift and position functions

BENEFITS

-

Precise Wafer Elevation & Support

Ensures accurate lifting and lowering of wafers during deposition, preventing surface contact that could damage delicate films. -

Vacuum & Clean Room Compatibility

Constructed from ultra-clean, low-outgassing materials to meet stringent vacuum and cleanroom requirements -

Stable, Repeatable Positioning

Provides micrometer-level repeatability to maintain uniform film thickness and precise process alignment

Etching – Wafer Handling System for Loading in Etch

YOUR VALUE STREAM NEEDS ...

- Reliable, contamination-free wafer transfer into critical etching environments

- Precise alignment, secure positioning, and smooth hand-off between cassettes, FOUPs, and etch chambers

Product Category:

SUB-ASSEMBLY

Delivery of ultra-reliable, contamination-free wafer transfer into critical etching environments

BENEFITS

-

Precision Alignment & Positioning

Ensures accurate wafer centering and orientation for reliable transfer into etch chambers. -

Seamless Automation Integration

Fully compatible with robotic arms, FOUP loaders, and factory automation (FA) systems for high-throughput operation. -

High Cycle Durability

Built for continuous 24/7 operation with proven mechanical longevity and minimal maintenance requirements.

Etching – Wafer Handling System for Wet Etch

YOUR VALUE STREAM NEEDS ...

- Suitability for pre- and post-etch cleaning

- High-quality particle and residue removal

- Minimized chemical consumption and wafer stress

Product Category:

SUB-ASSEMBLY

State-of-the-art single-wafer cleaning system for precision wet processing in semicon manufacturing

BENEFITS

-

Micron-Level Positional Accuracy

Precise lift height control ensures proper alignment with spray, immersion, or dispense nozzles. -

Ultra-Low Particle Generation

Clean, contact-optimized mechanics to minimize contamination during corrosive wet processing. -

Automation Ready

Integrates seamlessly with wet bench handling systems and robotic transfer modules.

CMP

YOUR VALUE STREAM NEEDS ...

-

Gentle handling:

Smooth acceleration profiles to prevent wafer slip or breakage -

Clean environment:

Antistatic design to reduce particle attraction -

Precise positioning:

Align wafers exactly at the input port of the next tool -

Integration:

Communication with both tools’ load ports and factory automation

Product Category:

SUB-ASSEMBLY

Spin Unit Polishing:

System for ultra-precise wafer handling during Chemical Mechanical Planarization

BENEFITS

-

Stable Rotational Control

Engineered for smooth, vibration-free spin motion to achieve defect-free planar surfaces. -

Chemical & Slurry Resistant

Materials constructed with corrosion-resistant components to withstand abrasive slurries and aggressive CMP chemistries. -

Seamless Tool Integration

Fully compatible with automated wafer handling and CMP process automation platforms.

Wafer Inspection & Test

YOUR VALUE STREAM NEEDS ...

- Precision and accuracy

- Throughput and cycle time

- Cleanliness and contamination control

Product Category:

SOLUTION SET

Wafer inspection & testing with ctrlX MOTION and linear systems

BENEFITS

-

Straightness and flatness of linear rails:

≤ 1 µm/100 mm -

Positioning repeatability:

≤ ±0.5 µm (X/Y), ≤ ±1 µrad (rotation) - Multi-axis coordinated motion with jerk-limited profiles for smooth, fast moves

- Closed-loop motion control with trajectory planning for X/Y/Z/θ axes

- Integration with SECS/GEM

Back-End

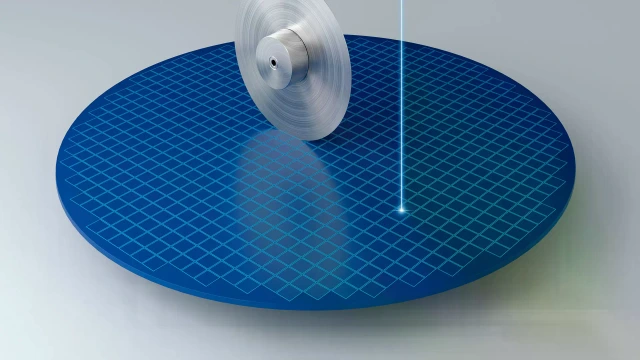

Wafer Back-Grinding

YOUR VALUE STREAM NEEDS ...

- Sub-micron linear positioning

- Cleanroom compliance

- High stiffness, vibration damping

- Spindle synchronization

Product Category:

SOLUTION SET

ctrlX MOTION with linear axes and integrated diagnostics

BENEFITS

- Drives with low backlash – high surface quality

- High repeatability – fewer rejects

- Scalable control system – fits any size

- Integrated diagnostics – reduced maintenance

- Predefined motion profiles – fast commissioning

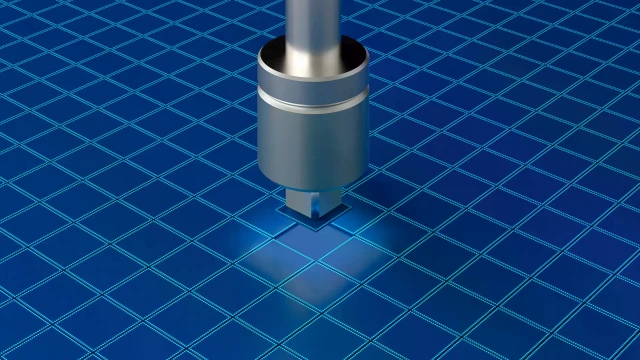

Wafer Dicing

YOUR VALUE STREAM NEEDS ...

- High-speed, backlash-free XY movement

- Vision-based path correction

- Sub-micron repeatability

- Cleanroom class 5-6

Product Category:

SOLUTION SET

Motion solution with XYZ control using ctrlX CORE

BENEFITS

- High-speed positioning – faster cuts

- Stable motion – precise blade movement

- Compact modules – cleanroom-ready

- Open automation interfaces – easy PLC/HMI link

- Diagnostics tool – fast troubleshooting

- Energy-efficient drives – lower costs

Chip Testing

YOUR VALUE STREAM NEEDS ...

-

Stage movement:

Repeatability; synchronization with optics/sensors, thermal compensation -

Chuck movement:

Smooth acceleration / deceleration, positioning accuracy (XYZ) -

Active damped wafer stage:

Precise movement, repeatability, accurate positioning

Product Category:

SOLUTION SET

Stage and chuck movement solutions with ctrlX MOTION, drives & controls and linear systems

BENEFITS

- Precise wafer alignment with inspection optics

- Prevents wafer slippage or vibration

- Consistent movement over time – process stability across temperature range

- Sub-nanometer precision for defect detection

- Accurate triggering of cameras or sensors during motion

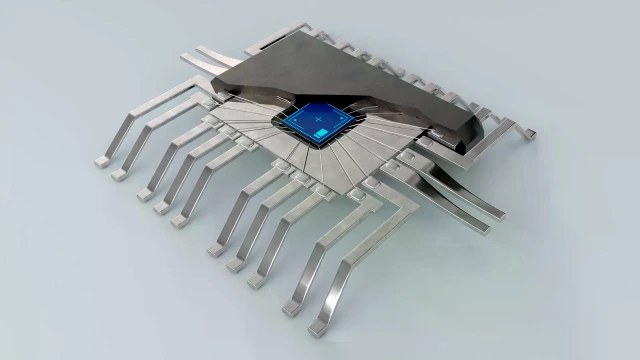

Die-Bonding

YOUR VALUE STREAM NEEDS ...

- Repeatability

- High positioning accuracy

- Thermal compensation & drift correction

- Synchronization with inspection optics / sensors

Product Category:

SOLUTION SET

Basic bonding motion solution (ctrlX Motion) + force loop integration

BENEFITS

- Components with precise Z-force control for high bonding quality

- EtherCAT integration for seamless communication

- Solution set with customizable HMI & control logic – less errors, safe usage

- Realtime feedback – reduced scrap

- Flexible system integration

Chip Molding

YOUR VALUE STREAM NEEDS ...

- Mold press force/position monitoring

- Rigid, thermally stable axes

- Process sealing & cleanliness

- Parallel axis actuation

Product Category:

SOLUTION SET

High-force motion kit with closed-loop control (ctrlX MOTION)

BENEFITS

- Components for precise mold closure – with no hydraulics

- Easy maintenance – low downtime

- Closed-loop pressure and position – high stability

- Custom motion profiles – product-specific control

- Reduced wiring – cleaner cabinet

Final Test

YOUR VALUE STREAM NEEDS ...

- High-speed indexing

- Integration with testers

- Repeatable placement

- Clean motion and safety

- Data capture

Product Category:

SOLUTION SET

ctrlX S-MOTION with modular HMI and vision interface

BENEFITS

- Components enabling high dynamics and precision motion – for fast test cycles and accurate results

- MES-ready connectivity – digital factory fit

- Scalable motion hardware and software – easy updates

- Flexible integration with existing test lines – reduced CAPEX

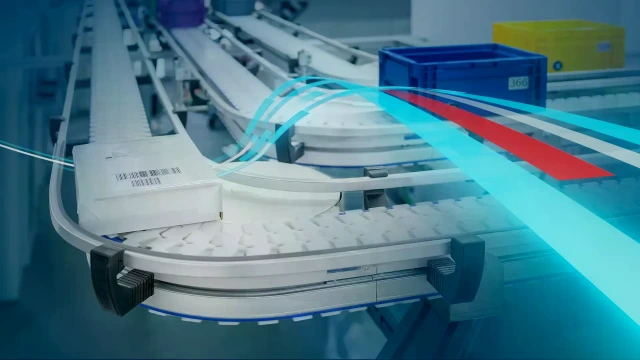

Electronics Production

Surface Mount Technology (SMT)

Soldering

Focus products:

Inspection

Focus products:

Chip Transport

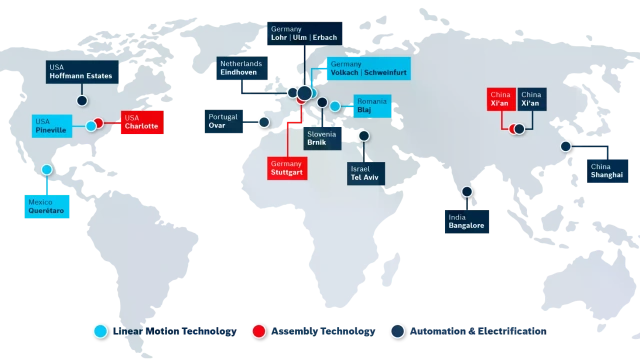

Manufactured for scalability

Trust, speed, and a common language – these are the advantages of working with our global team of experts. Located at the heart of the semiconductor industry’s hotspots, we bring together a wide range of expertise. Beyond leading engineering, you can rely on an extremely high level of vertical integration, which makes our products independent of supply chain issues. With our global manufacturing network, we are where you are.