How can typical pressing and joining processes be brought into the line straight out of the box and made transparent? The Factory of the Future starts now!

Have you ever designed, configured and programmed a subsystem for pressing, joining, forming, inspection or testing? Then you are probably also familiar with the time involved and the numerous possible sources of error until production can finally start. What if you could show the cost-eaters in engineering the red card and order your applications ready-made as a complete solution with automated commissioning and graphical process creation? Take the next step towards the Factory of the Future with Bosch Rexroth and use our smart system toolbox for pressing and joining applications!

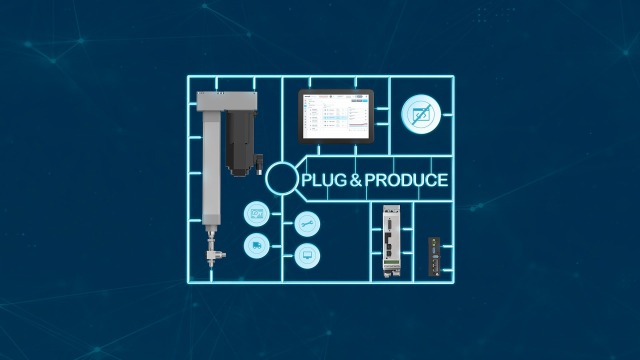

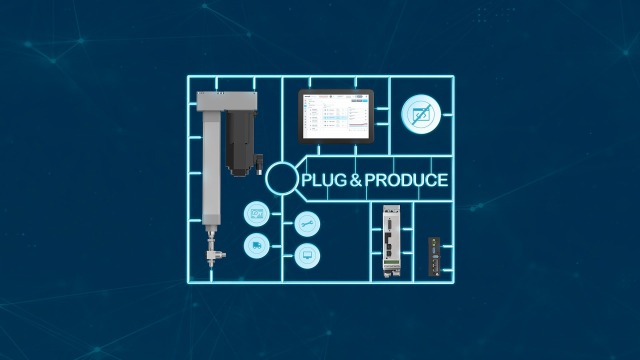

Subsystem for a wide range of applications: the Smart Function Kit for pressing and joining applications combines mechanics, electrics and software to form a plug and produce solution.

The Smart Function Kit for Pressing, a complete mechanical, electrical and software package, can be ordered with a single material number and is delivered in a package with pre-installed operating software. On site, a wizard guides you through the commissioning process in just a few minutes. Process creation is also a breeze: Via the intuitively operated web HMI, the sequence can be assembled simply by dragging and dropping prepared modules, which then only have to be filled with the appropriate parameters.

Do you want to know which processes you can now simplify radically?

Thanks to the prepared function blocks, the connection to the line control is just as easy as the data exchange via OPC UA. The pre-installed software package ensures that the plug-and-produce subsystem can be used immediately, which significantly shortens time-to-market. For optimal transparency during operation, process and status information is visualized in the dashboard – including live display of the force-displacement curve and display of the evaluation result (OK/NOK). Traceability is also ensured, as the Smart Function Kit stores all process data including quality assessment in an internal database.

Experience the Smart Function Kit Pressing in a video:

All in all, what can the Smart Function Kit for Pressing do for your engineering? In our experience, it offers up to 80 percent time saving. And that’s by far not all. Together with the guided commissioning and simple programming including process evaluation, the time-to-market is also shortened. And the Factory of the Future moves one step closer. My tip: Start smart now and benefit sustainably!