The new TASS (Torque Angle Slip Standard) verification system from Bosch Rexroth is a groundbreaking method for verifying safety-critical tightening connections. Thanks to the on-the-fly process, quality can be ensured directly at the workplace. By integrating the verification of the tightening tool into the assembly process, downtime is minimized and possible deviations are identified during ongoing production. Start a new era of joining technology with TASS – the fully automatic verification system from Bosch Rexroth.

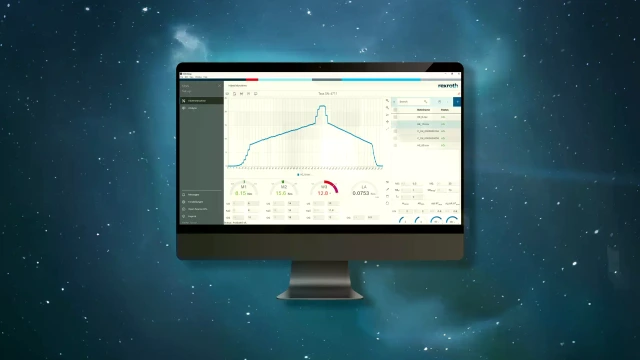

Bosch Rexroth offers a new way to validate your tightening technology with the TASS in short cycles and without removing it from the system. TASS stands for Torque and Angle Slip Standard, so the name already indicates that the torque and angle of rotation are tested in a single test run using a dimensional embodiment. The test itself takes only a few seconds, and you will receive immediate feedback on the test result.

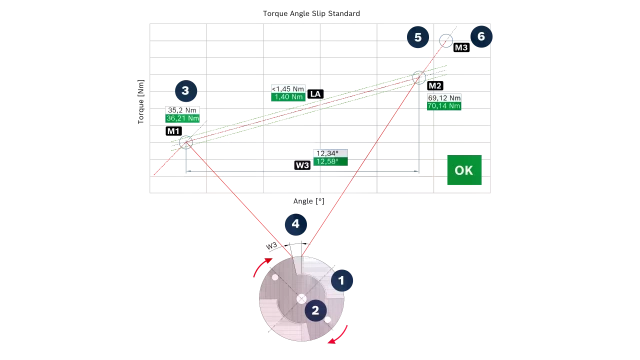

The operating principle of TASS

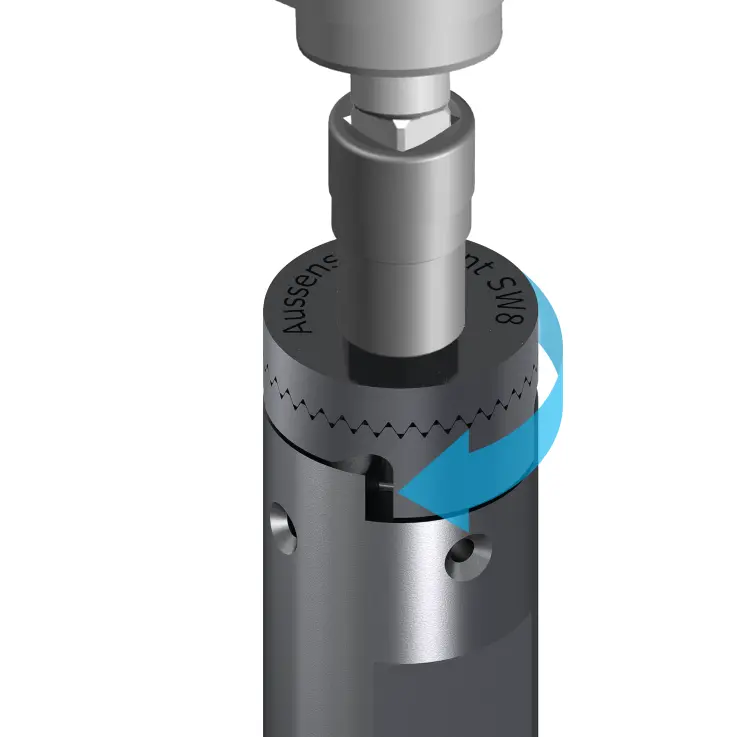

- In a TASS verification, a torsion shaft is driven with the tightening tool, which represents a specific and consistent dimensional embodiment.

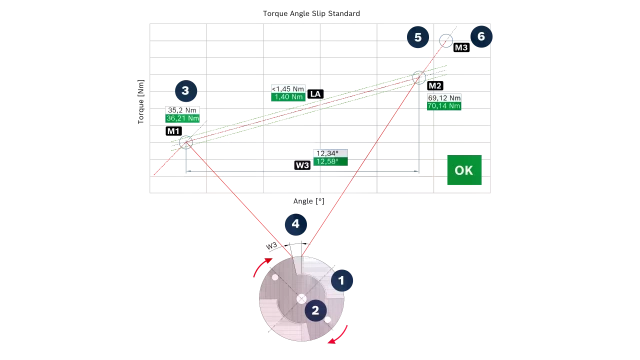

- During the rotation of this torsion shaft by the tightening tool, two torque values, the angle of rotation between the fixed stops, and the linearity of the torque curve are checked.

- The values determined during the verification in the manufacturing plant are compared with values from the calibration of the TASS verification system, and immediate feedback on the result of the verification is provided to the plant control system.

Learn more about the TASS verification system

The Physics Behind TASS

TASS verification system catalog

Get the complete overview of the TASS verification system here.

Included in the catalog:

- Detailed information on the TASS verification principle

- Overview of components and software

- Order information for TASS elements and accessories

- Dimensional drawings and technical data