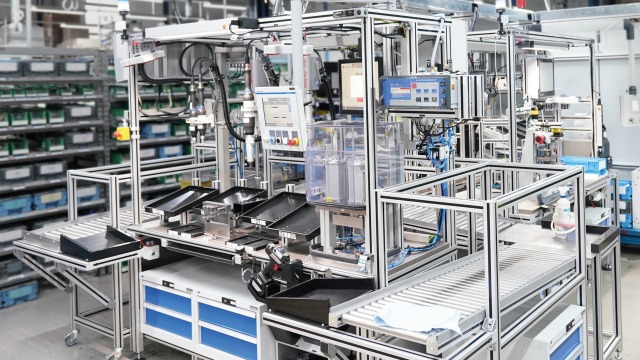

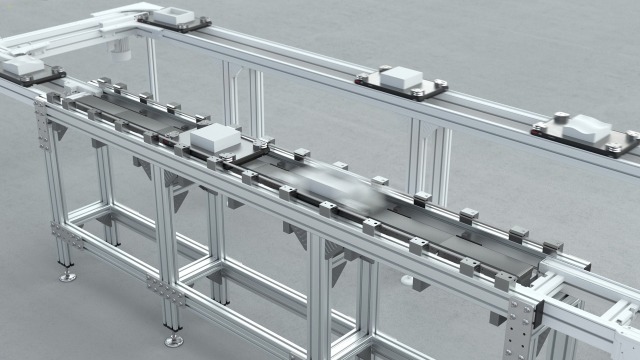

ESD protection for production systems

Find out more in this video about how we can assist you in terms of ESD protection with our production systems as Bosch Rexroth! Technical backgrounds, characteristics of different production areas, as well as measuring and testing of ESD components are part of this eTraining.