Free professional day at the site of Bosch Rexroth Kft.

Industry 4.0 - Solutions of the future

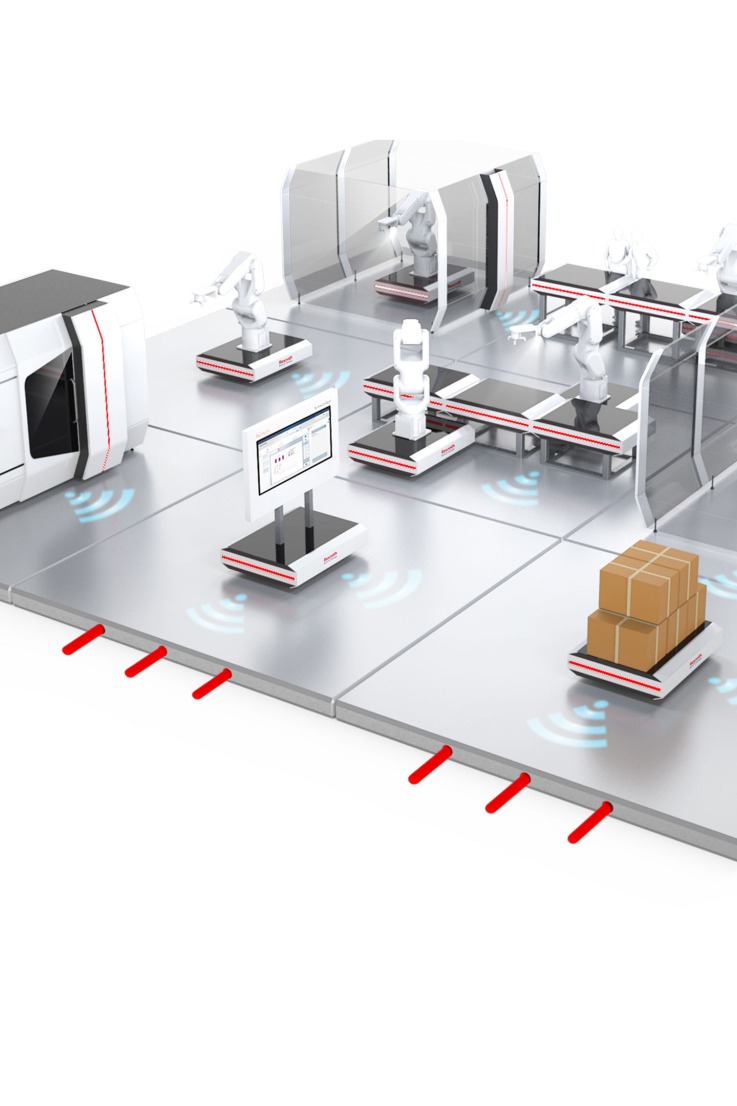

Take the first step towards Industry 4.0 and learn more about this approach and the latest technologies. Take part in our one-day professional presentation where you can see the products that shape the trends of production automation up close. Our experts present the APAS collaborative production assistant, the ActiveShuttle intralogistics robot, ctrlX automation, which is referred to as the smartphone of automation. On the mMS 4.0 training equipment, participants can model all the functions of a real Industry 4.0 production process.

Advantages of the professional day:

- Industry 4.0 approach directly from the developers

- Real Industrial Environment and Solutions

- Understanding Rexroth technologies and innovations

For more information and dates, please fill in the form and our colleague will contact you.

Apply to our Industry 4.0 trainings to gain more in-depth knowledge

Industry 4.0

The aim of our one-day training is to give the participants a comprehensive view of the goals and benefits of Industry 4.0, and to get to know the approach behind the idea. After reviewing the changes in industrial-technology developments, we will present in detail the new production needs and challenges for which Industry 4.0's toolbox, networked production and its conditions offer effective solutions. In the current Annex I, After outlining the 3.0 mechatronics and automated systems, we present the basic measures of digitized production and digitization, the concept and structure of the intelligent workstation, and the role of cyber-physical systems in the production processes. We describe the RFID-based identification system and its application areas. Through the MES production process monitoring system, we present modern solutions for integrated production management, real-time process management and visualization. We deal in detail with the robot integration in the structure of Industry 4.0, traditional and collaborative robotics. The application of Industry 4.0 and its potential are brought closer to the participants through concrete case studies, showing the interfaces between Industry 4.0 and traditional mechatronics systems.

- Duration of training: 1 day

- Training fee: HUF 50,000/person

- Optimal number of training participants: 10 persons

Industry 4.0 – digitised production

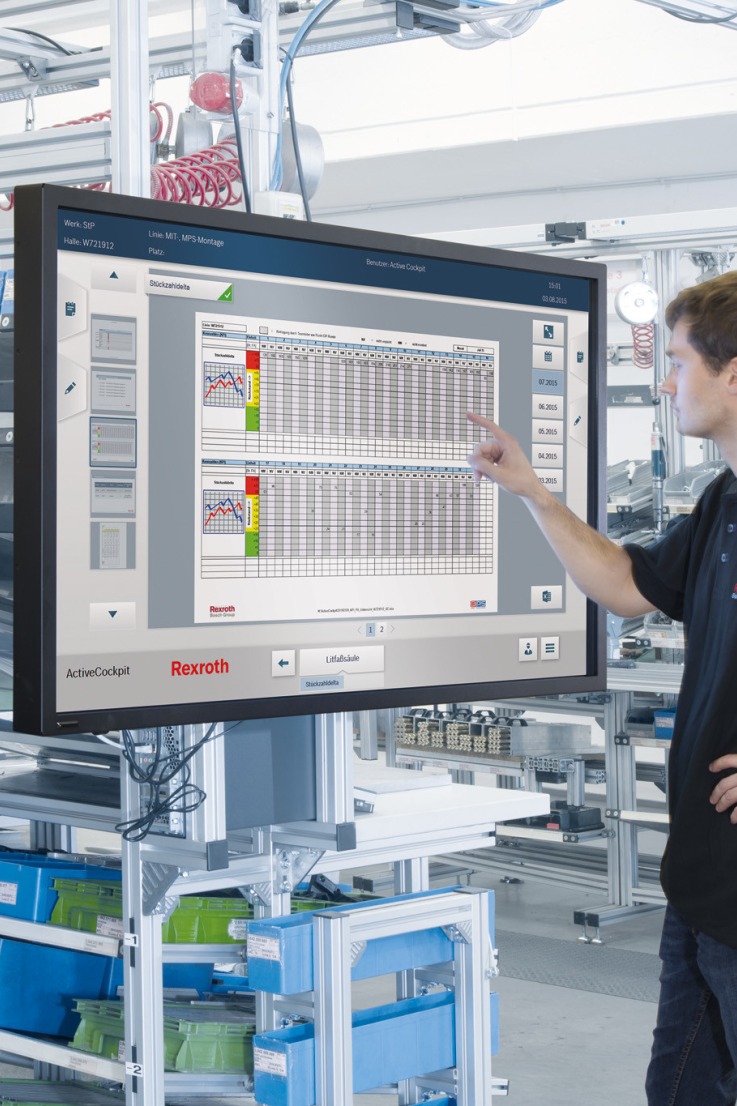

Participants of the training can get a grasp of the approach applied in Industry 4.0, the structure and requirements of the connected production line as well as all functions of a complete production system. The benefits of real-time data management and of the interconnection between the virtual model and the simulation will be presented. To achieve this, participants will practise interactive data display and analysis, the use of interactive communication platform ActiveCockpit and the operation and error diagnostics of the equipment using an mMS4.0 miniature production line developed from industrial modules for this purpose. Using the Open Core Engineering, participants can acquire the basics of PLC programming with high-level programming languages. Participants can learn about the options of connecting production data and ERP systems, the method of monitoring material flow using the RFID system and, as a result, get to know the basics of product-controlled manufacturing. The collection method and analysis of equipment and process data is also introduced using a web-based software with the aim of ensuring process optimization, quality assurance and plannable maintenance. During the training, participants will acquire the knowledge and skills required in the factory of the future.

- Duration of training: 3 day

- Training fee: HUF 150,000/person

- Optimal number of training participants: 6-8 persons