FRAME YOUR FACTORY –

with low-carbon aluminum profiles

The industry is changing: Resource scarcity, rising energy prices and stricter carbon tariffs, such as the Carbon Border Adjustment Mechanism (CBAM), demand sustainable action. Companies are facing the challenge of adapting their processes to reconcile environmental responsibility with economic efficiency.

At Bosch Rexroth, we are proceeding step by step in our efforts to make our products and processes more resource-efficient. For over 40 years, we have been developing aluminum profiles that meet the most exacting demands in terms of quality and flexibility. Our low-carbon aluminium profiles are made from raw material (billets) with a significantly lower Product Carbon Footprint (PCF of ≤ 5 kg CO₂eq/kg Al)1. With the introduction of low-carbon aluminum profiles as the new standard in our modular profile system, we are opening a new chapter that combines technological excellence with unwavering commitment to sustainability.

Our low-carbon aluminum profiles retain the proven strength of our system: one of the world's largest selections of aluminum profiles. They enable tailored and efficient solutions for machine frames, safety fences, ergonomic workplaces, or a lean material supply. Plan and realize your projects while reducing the carbon footprint of your solutions.

Full transparency for your carbon footprint

Future-proof solutions start with the right information. Our digital backbone is made up of a central database that maps each of our products as a digital twin. For you, this means that all relevant technical data is available as and when you need it.

We provide transparent PCF (product carbon footprint) values for all our standard components. Utilize these exclusive product carbon footprint calculations for a transparent carbon footprint.

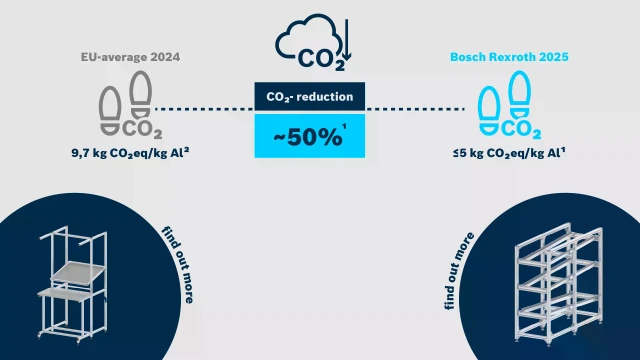

CO₂ savings compared

Sources:

1 We are reducing the product carbon footprint (PCF) of our aluminum profiles by using raw materials (billets) with a significantly lower PCF value (Scope 3 upstream) starting in 2025. These billets have a PCF of ≤ 5 kg CO₂eq/kg Al. This is almost 50% less than the European average of 9.7 kg CO₂eq/kg Al for primary aluminum used in Europe (European Aluminium, Environmental Profile Report, Nov. 2024).

2 European Aluminium, Environmental Profile Report, Nov. 2024.

3 International Aluminium Institute (IAI), 2023.

4 A beech tree absorbs 12.5 kg of CO₂ per year; CO₂ reduction in comparison to the EU average.