- Data collection and transfer device

- Data are available from anywhere thanks to the web interface – remote diagnostics possible

- Historically retrievable data

- Send an alarm at preset thresholds

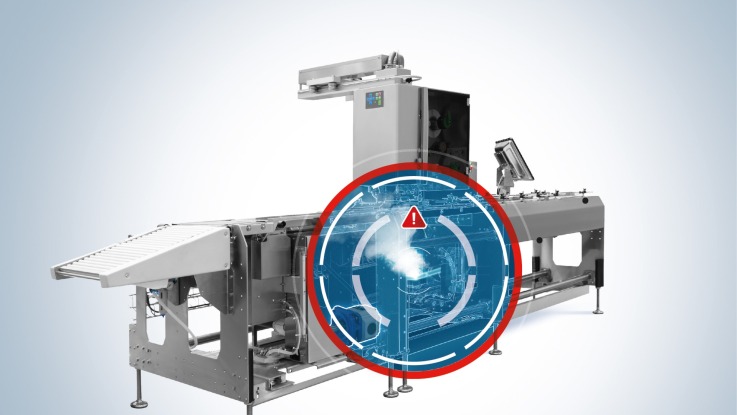

Even if you don’t know, it could be a big problem

An unexpected stop and the associated service always comes at the wrong time and takes too long. But with careful planning, all this can be avoided! Rexroth's predictive maintenance solutions keep the machine condition under constant control, so that downtime can be planned in advance and unexpected machine downtime costs can be saved.

Customer benefits

- Reduction of downtime costs

- Improving efficiency and product quality

- Avoiding a total loss of production

- Reduction of storage costs

- Simple and secure cloud solution

- Secure one-way data connection

Cases of use and examples in preventive maintenance (Hungarian)

Download the eBook and learn more about solutions to get you started on predictive maintenance.

Read more

Key features

Technical data:

-

Data endpoints: up to 19

- standard: 8A/3D

- ext. "A": +8A

- ext. "B": +5D

-

Sampling rate:

- 100 ms (=10/sec =10 Hz)

- Database and software integration: closed system with dashboard

Advanced level based on IoT Gateway

Product benefits:

- Quick to commission and configure - No programming required thanks to pre-configured connection interfaces

- Can be installed next to the machine, does not interfere with its control

- Makes all machine operating parameters visible

- Makes the data of sensors, PLCs, clouds, IT and IoT protocols available

Technical data:

-

Data endpoints: up to 2000

- Normal: 25

- Enhanced: 500

- Performance: 2000

-

Sampling rate

- o Basic: 100 ms (=10/sec =10 Hz)

- o Up to: 1 ms (= 1000/sec =1 kHz)

• Database and software integration: any database, BCI and other software

Read more

Product benefits

- Higher availability with permanent automated monitoring of machine data

- Reduced costs due to lower downtime

- Up to 50% faster maintenance

- Increased productivity

- Reduced spare parts storage cost

- Our experts help to develop a data-based analysis and maintenance strategy

- Additional Rexroth services

Technical data:

- Data endpoints: up to 2000 based on IoT Gateway

-

Sampling rate:

- Basic: 100 ms (=10/sec =10 Hz)

- Up to: 1 ms (=1000/sec =1 kHz)

- Database and software integration: ODiN SW solution