Maintenance and repair of hydraulic power units and components all too often confront technicians with major challenges. Ordered spare parts, often seals, arrive in unlabeled bags, and the technician has to struggle through manuals until he gets the appropriate support. It is different at Rexroth: The hydraulics specialist has switched to over 15,000 ready-made spare parts kits with all the necessary installation documents. In addition, Rexroth's eShop on the Internet makes it much easier to find and order the right spare parts. The result: time savings of 50 percent in in-house repairs, lower overall costs and longer service life.

It is not always profitable to call the service of the machine manufacturer or the hydraulic supplier for every problem. Many users carry out minor repairs and regular maintenance on their own, even if the manufacturers often do not make it easy for them. This begins with the time-consuming search for the right and necessary spare parts for the repair, through to ordering via paper and then rolling through manuals.

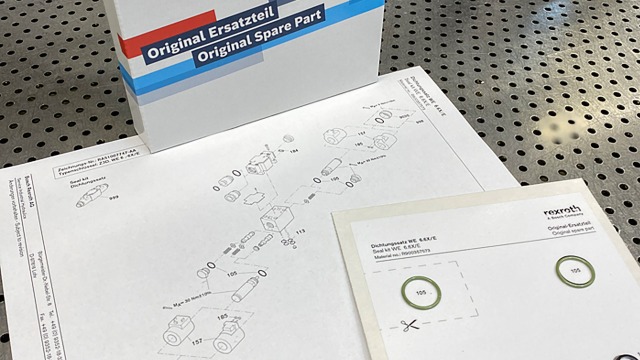

Rexroth has significantly simplified this process and thus helps to reduce the life cycle costs of hydraulic systems even further. More than 15,000 spare parts kits cover almost all Rexroth components and systems still in use. These range from switching valves, continuous valves, hydraulic pumps, hydraulic accumulators, power units and systems, blocks and interlinked systems, compact hydraulics, cylinders and special cylinders. Low-value spare parts or those that should be replaced in one-step are logically combined in one package. For example, a spare parts kit for pumps consists of all wear parts that should be replaced when the pump is removed: seal kit, rotor and control disc. The spare parts are adapted to the respective pump design. All spare parts kits contain a parts list and a clear exploded drawing for installation.

Around 98 percent of the spare parts kits consist of seal kits. The seals used at Rexroth are subject to strict criteria in terms of material, manufacturer and quality, as these are decisive in hydraulics for the tightness, performance and service life of the systems. This begins with the correct dimensions of a seal for a given installation space. Without appropriate design tools, it becomes very difficult for the user to find a working solution. Rexroth-specific R-ring seals in particular - in comparison to the somewhat simpler O-rings - cannot be designed with externally available online tools.

Errors can also easily occur in the material. For example, the common designation NBR says little about the exact composition and thus about the mechanical, thermal and chemical resistance. Of the numerous seal manufacturers on the market, hundreds of so-called compounds are available, the differences between which can only be determined by extensive testing and whose service life in the hydraulic system varies enormously.

The seal kits therefore contain the original seals of Rexroth hydraulic components, i.e. also the correct materials in original equipment quality, optimally matched to the installation situation.

The complete seal kits from Bosch Rexroth always contain all necessary sealing rings for maintenance. A uniform packaging system with standardized cartons protects the spare parts from negative environmental influences and simplifies storage by the user. The seals are individually welded onto seal kit supports and protected against oxygen, light and UV radiation. This prevents deformation, hardening, ageing, corrosion and weathering, especially in the case of sensitive high-performance seals, even during long periods of storage. This allows the user to exploit the full service life of the seals in the system.

Almost any spare parts kit includes a parts list and an exploded drawing. This is an important simplification of work, especially with older machines and systems, where the paper documentation is often no longer available or incomplete. The description reduces the average time required for disassembly, cleaning of old seals to establish an allocation and assembly when repairing a pump, for example, from a good two hours to less than 60 minutes. These times are taken from field observations where the workload of skilled technicians was measured. In addition to the significantly reduced working time, the clear repair instructions prevent errors during assembly and thus also increase the functional reliability considerably. This effect significantly increases with the complexity of the repairs.

And another advantage: the costs of the sealing kits are negligible compared to the total cost of replacement including removal and reinstallation of the component.

Those who want to save costs in the short term - by using non-original spare parts - pay extra in the long term. To reduce the total cost of ownership, components should be professionally repaired to achieve the longest possible service life. Because only with proven manufacturer specifications can the original performance data and thus function, productivity and efficiency be guaranteed.

Link to the eShop: www.boschrexroth.com/SpareParts