Car manufacturers are increasingly passing on responsibility for quality assurance to supplier companies. These companies thus need intelligent subsystems which can be put into use at short notice. Best practice: With the Smart Function Kit Pressing from Bosch Rexroth, KMS Automation can realize pressing and joining applications quickly and easily.

A global automotive supplier played a decisive role in standardizing the quality-relevant joining process. Initially, KMS Automation wanted to develop the required QA function for the ordered assembly line itself, but this quickly proved to be too costly. Instead, the company which specializes in automation technology, fixture manufacturing and special machine construction relied on - the Smart Function Kit Pressing plug-and-produce subsystem from its long-standing system partner Bosch Rexroth.

The Smart Function Kit Pressing is a complete mechatronic package comprising an electromechanical cylinder, servo motor, servo drive, industrial PC, force sensor and software. In the system equipped with it, the Smart Function Kit is the central component in the first of five assembly stations. Its task is to guide an approx. 250 mm long tube electromechanically through the interior of an aluminum oil pan and press it into the space provided with a defined force. Later on, the drive shaft of the vehicle will run through the tube which is also secured using adhesive. Alongside the joining process, the subsystem records the process data, evaluates them and passes them on to a higher-level IT system for quality assurance.

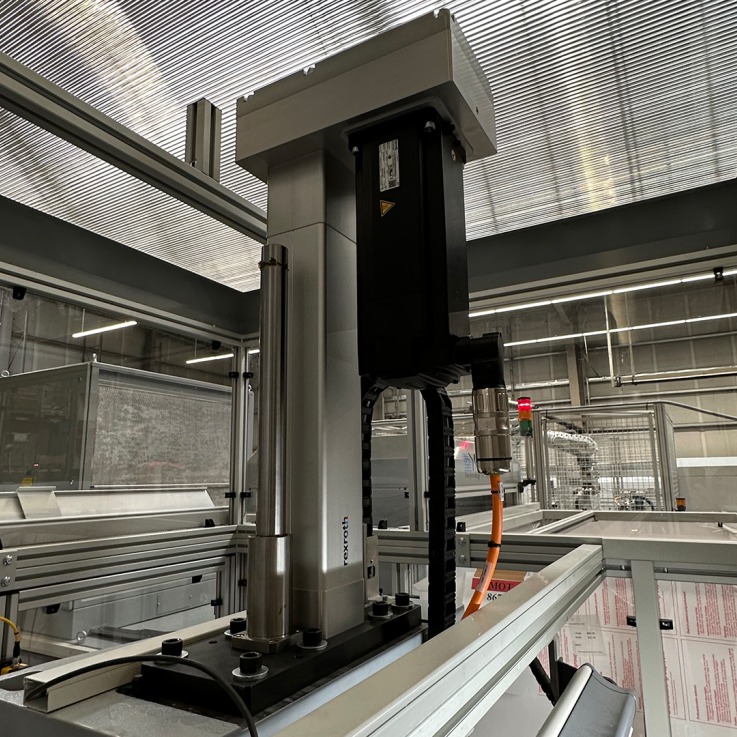

Assembly station with oil pan seating (bottom), the tube to be pressed in (middle) and the Smart Function Kit Pressing (top, in the background). (Copyright: KMS Automation)

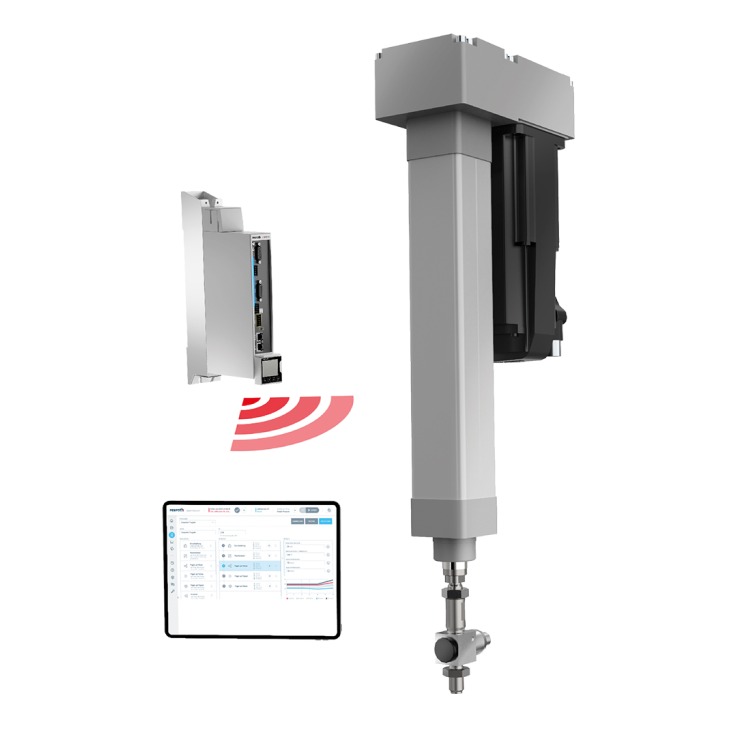

The force sensor is ordered along with the Smart Function Kit Pressing as an optional extra and is supplied as part of a preconfigured complete package. (Copyright: KMS Automation)

In the past, KMS Automation had mainly implemented comparable applications with high forces using fluid technology, which was relatively complex and time-consuming. “A versatile mechatronic subsystem like this that comes complete from a single supplier saves us valuable time – time that we can invest in finding creative solutions,” said Managing Director Klaus Wurster. “Standardization speeds up not only engineering and commissioning processes but also purchasing and servicing.”

With the mechatronic kit from Bosch Rexroth, the mechanical engineering company can now standardize applications involving forces of 2 to 70 kN systemically. Versions with axial or parallel motor mounting allow flexible integration into various system designs. The desired connection to the line control via fieldbus can be achieved quickly and easily using the function block provided.

Thanks to the process information, which is provided via open interfaces, KMS Automation was able to significantly speed up and simplify quality assurance and documentation. Communication between the safety devices and the Smart Function Kit takes place via PROFIsafe. Among other things, this ensures that a safe maximum speed is not exceeded and – in the situation that a person reaches into the surrounding light grid – the transition to a safe standstill is initiated and monitored ensystem will come to a safe standstill and then be monitored.

Everything from a single source: The selected Smart Function Kit with a 19 kN pressing force and a 300 mm stroke is mounted on a steel framework: KMS Automation produced the rest of the machine frame using elements from the Bosch Rexroth aluminum profile toolkit. (Copyright: KMS Automation)

The Smart Function Kit Pressing combines mechatronic standard components with intuitive operating software for quick commissioning, graphical sequencing, straightforward line integration and integrated process data collection. (Copyright: Bosch Rexroth)

Klaus Wurster regards the Smart Function Kit as an important step on the way to simplifying previously work and cost-intensive tasks: “Many of our systems now have a purely electromechanical design. This not only reduces machine complexity – it also allows us more freedom in process design with greater precision. Ultimately, even shorter cycle times are possible because the finely adjustable electromechanical system allows different speeds. In light of the far-reaching simplifications and time savings, we will use the modular subsystems and proven components from Bosch Rexroth wherever possible in the future.”

Incidentally: The enhancements to the software that have been incorporated over the course of joint further development benefit all Rexroth customers. After all, the updates for the Smart Function Kit are available for downloading free of charge.