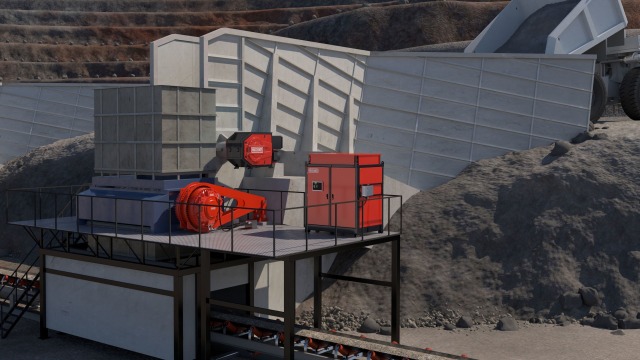

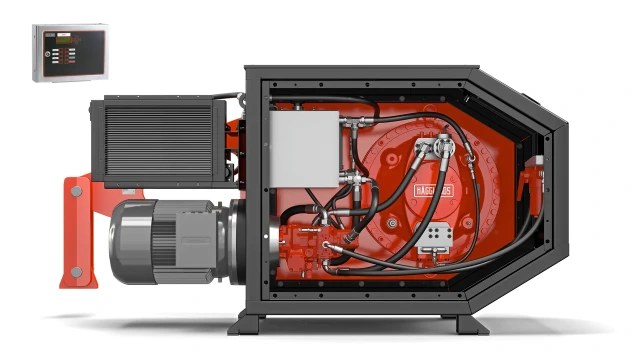

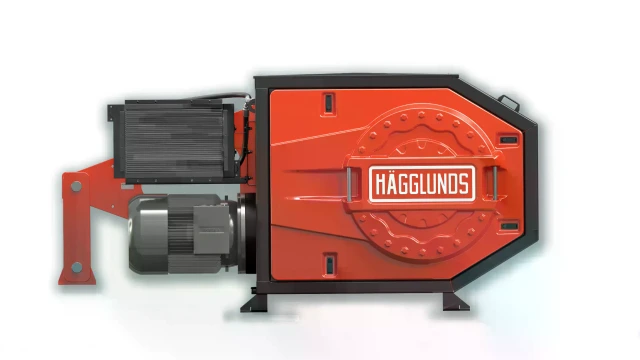

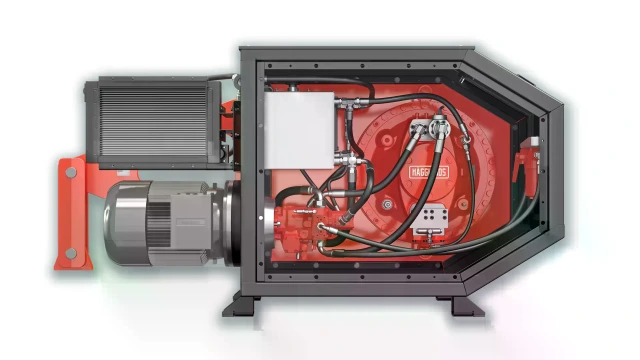

The Hägglunds Fusion drive systems, introduced to the market in February 2022, set a new standard among compact hydraulic drives. Why? For the first time, the entire system - motor, pumps, and housing - has been integrated into a single module that can be easily mounted directly on the torque arm.

Technical Data

| Pump cc | ||||||||

|---|---|---|---|---|---|---|---|---|

| 28 | 40 | 56 | 71 | 90 | 125 | |||

| Running Torque | Hydraulic Motor | Frequency | Electric motor kW (hp) | |||||

| 22 (30) | 30 (40) | 37 (50) | 46 (60) | 55 (75) | 75 (100) | |||

| 9.5 kNm | CA 50 | 50Hz | 0 - 11.0 rpm | 0 - 15.7 rpm | 0 - 22.0 rpm | 0 - 27.9 rpm | 0 - 35.3 rpm | 0 - 49.0 rpm |

| 60Hz | 0 - 13.2 rpm | 0 - 18.9 rpm | 0 - 26.4 rpm | 0 - 33.5 rpm | 0 - 42.5 rpm | 0 - 59.0 rpm | ||

| 13 kNM | CA 70 | 50hz | 0 - 7.8 rpm | 0 - 11.2 rpm | 0 - 15.7 rpm | 0 - 19.9 rpm | 0 - 25.2 rpm | 0 - 35.0 rpm |

| 60hz | 0 - 9.4 rpm | 0 - 13.5 rpm | 0 - 18.9 rpm | 0 - 23.9 rpm | 0 - 30.3 rpm | 0 - 59.0 rpm | ||

| 19 kNm | CA 100 | 50Hz | 0 - 5.5 rpm | 0 - 7.8 rpm | 0 - 11.0 rpm | 0 - 13.9 rpm | 0 - 17.7 rpm | 0 - 42.1 rpm |

| 60Hz | 0 - 6.6 rpm | 0 - 9.4 rpm | 0 - 13.2 rpm | 0 - 16.7 rpm | 0 - 21.2 rpm | 0 - 24.5 rpm | ||

| 27 kNm | CA 140 | 50Hz | 0 - 3.9 rpm | 0 - 5.6 rpm | 0 - 7.8 rpm | 0 - 9.9 rpm | 0 - 12.6 rpm | 0 - 29.5 rpm |

| 60Hz | 0 - 4.7 rpm | 0 - 6.7 rpm | 0 - 9.4 rpm | 0 - 12.0 rpm | 0 - 15.2 rpm | 0 - 21.1 rpm | ||

| 40 kNm | CA 210 | 50Hz | 0 - 2.6 rpm | 0 - 3.7 rpm | 0 - 5.2 rpm | 0 - 6.6 rpm | 0 - 8.4 rpm | 0 - 11.7 rpm |

| 60Hz | 0 - 3.1 rpm | 0 - 4.5 rpm | 0 - 6.3 rpm | 0 - 8.0 rpm | 0 - 10.1 rpm | 0 - 14.0 rpm | ||

| 54 kNm | QMX 280 | 50Hz | 0 - 2.0 rpm | 0 - 2.8 rpm | 0 - 3.9 rpm | 0 - 5.0 rpm | 0 - 6.3 rpm | 0 - 8.8 rpm |

| 60Hz | 0 - 2.4 rpm | 0 - 3.4 rpm | 0 - 4.7 rpm | 0 - 6.0 rpm | 0 - 7.6 rpm | 0 - 10.5 rpm | ||

| 76 kNm | QMX 400 | 50Hz | 0 - 2.0 rpm | 0 - 2.7 rpm | 0 - 3.5 rpm | 0 - 4.4 rpm | 0 - 6.1 rpm | |

| 60Hz | 0 -1.7 rpm | 0 - 2.4 rpm | 0 - 3.3 rpm | 0 - 4.2 rpm | 0 - 5.3 rpm | 0 - 7.4 rpm | ||

| 108 kNm | QMX 560 | 50Hz | 0 - 2.0 rpm | 0 - 2.5 rpm | 0 - 3.2 rpm | 0 - 4.4 rpm | ||

| 60Hz | 0 - 2.4 rpm | 0 - 3.0 rpm | 0 - 3.8 rpm | 0 - 5.3 rpm | ||||

| 160 kNm | QMX 840 | 50Hz | 0 - 1.7 rpm | 0 - 2.1 rpm | 0 - 2.9 rpm | |||

| 60Hz | 0 - 2.0 rpm | 0 - 2.5 rpm | 0 - 3.5 rpm | |||||

| Starting torque is up to 1.7 x running torque |