Reach a continuous improvement process at all levels of the company.

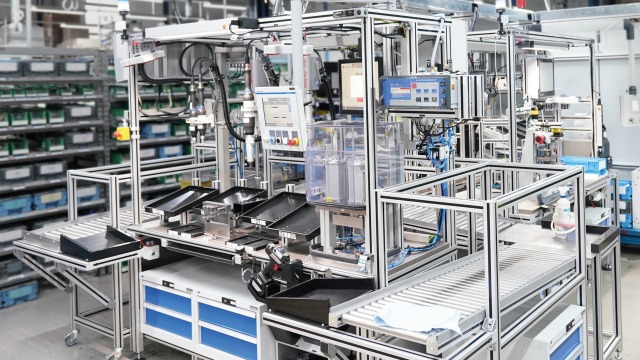

for efficient and customized manufacturing

Key for greater productivity and shorter throughput time

The constantly growing cost pressure makes it necessary to continually increase productivity in manufacturing. One central aspect is the detection and avoidance of waste (Muda). Bosch Rexroth’s broad range of prodcuts provides you with first-rate modules for realizing leaner production processes. You only produce what the customer needs – just in time and according to the zero-defect principle.

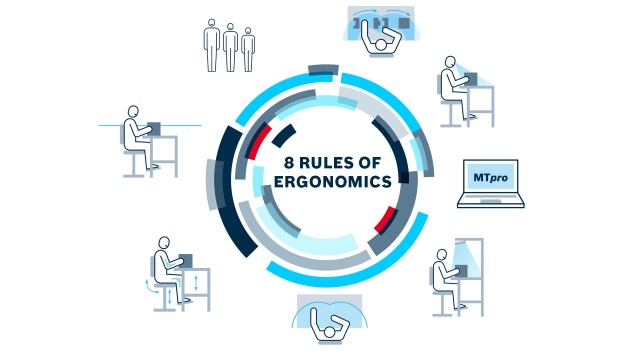

Lean by avoiding the 7 types of waste in production

Waste refers to all process steps that do not directly contribute to adding value. This waste should be avoided be continually reduced, with the aim of creating virtually waste-free production. In order to achieve this, the causes of waste must be identified and eliminated. This constitutes a continuous improvement process (Kaizen) at all levels of the company.

Seven types of waste

Waste in production? Using the simple example of a father who prepares waffles for his children arriving from school, the seven types of waste are presented in a practical, everyday example.