Starter Kit: production performance manager and IoT gateway

The IoT Gateway is available as a stand-alone solution and as part of a Starter Kit.

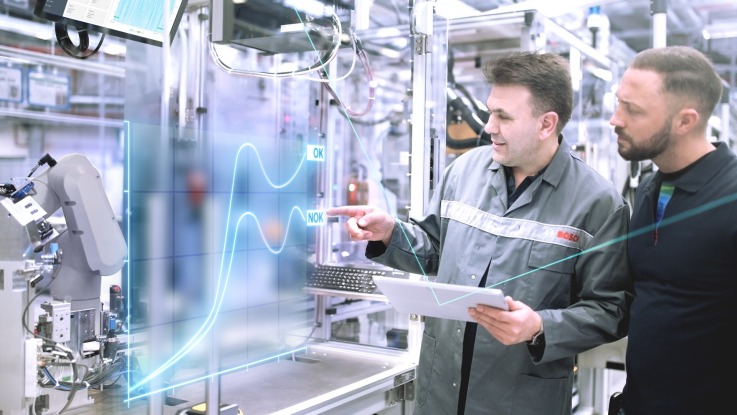

The Starter Kit contains in addition to the IoT Gateway the Production Performance Manager from Bosch Software Innovations. The software merges the collected information into one visualization and forwards specified events to defined persons.

With the Starter Kit, you can find out almost immediately how ready your production facility is for Industry 4.0. The combination of expert knowledge, software, and hardware provides you with a simple and cost-efficient way of networking your machinery and systems. You can then use the new information you gain to improve your production processes and product quality.

We will work with you to develop an initial custom use case, integrate the relevant machinery into the software solution, and identify potential for optimization so as to improve your production.

Additionally, we will provide you with the IoT Gateway hardware element in order to ensure a seamless collection and monitoring of data. We will support you in the installation of the hardware and software at a commonly defined machine. You will also learn how to integrate, digitally visualize, and optimize more production machinery, systems, and lines yourself.