- Home

- Products

- Industrial Solutions

- Resistance Welding

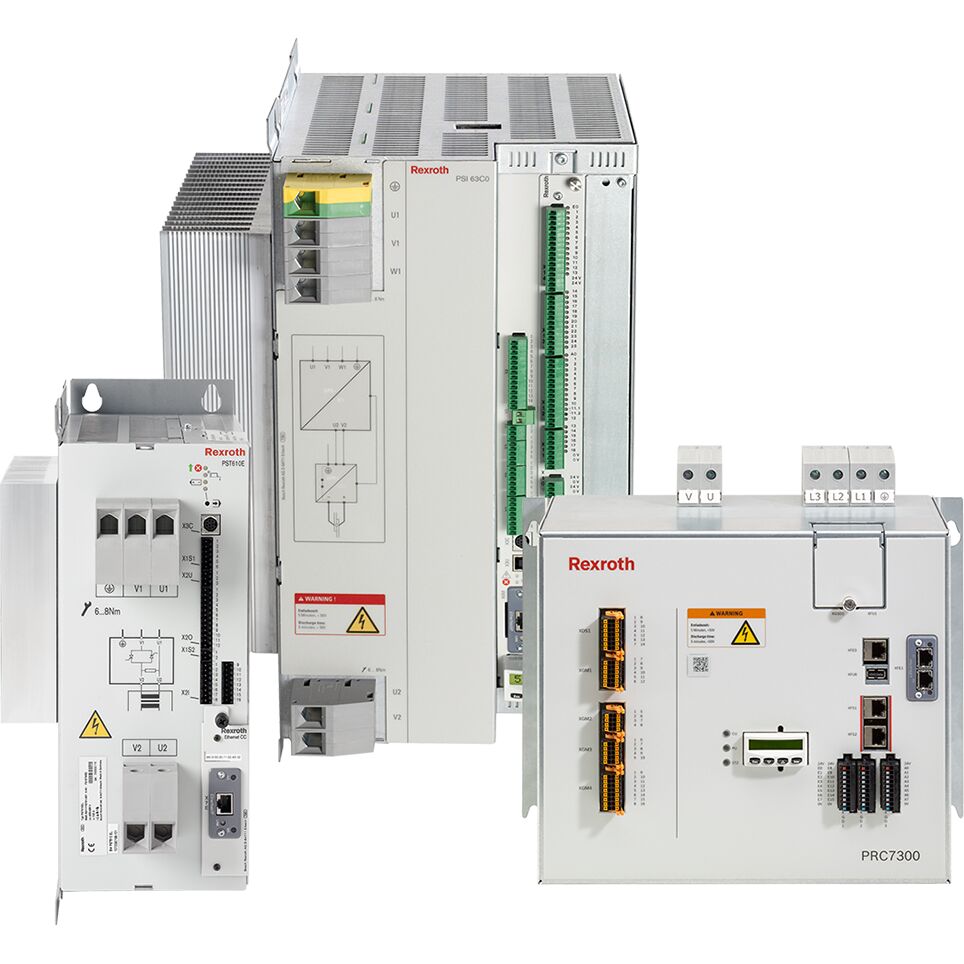

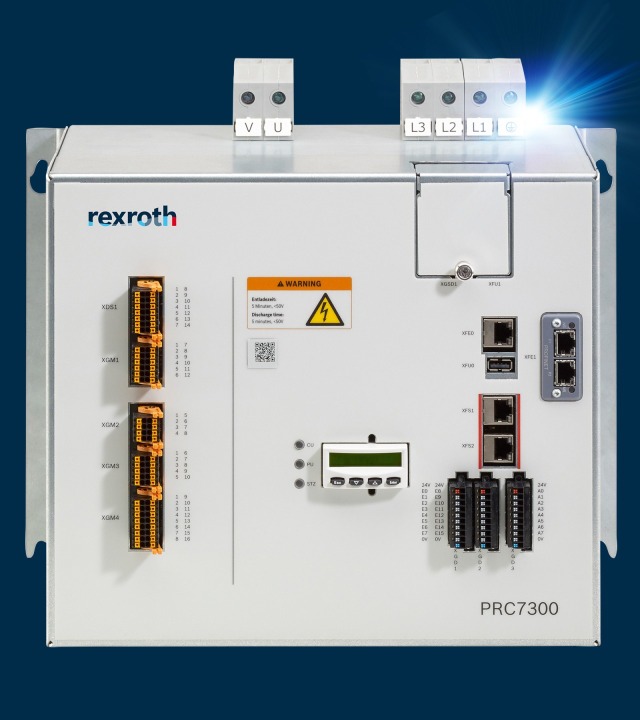

Future-proof your portfolio and discover the next level of resistance spot welding with the new, powerful PRC7000 welding control system.

Resistance Welding –

Not all types of welding are the same

Difficult material combinations, higher expectations in terms of quality and productivity, and new system technologies require greater performance in welding. At the same time, Industry 4.0 capability is in demand in modern factories. Bosch Rexroth has the answer with the welding control PRC7000. It enables precision welding of different materials and has functionalities to make processes future-proof and simpler.

Sounds too good to be true? Living proof: PRC7000

Weld quality to the point: With the new, powerful welding control PRC7000, perfect weld spots finally become reproducible. What else makes it so indispensable and future-proof? Adaptive controls and flexible programmability allow for different sheet thickness combinations and material mixes – from steel to aluminum – to be easily processed. The integrated IoT connector, which provides structured data for central processing, quality control and technology data management, makes PRC7000 ready for Industry 4.0

Product Details

Weld Spot Analytics

OUR MISSION Weld Spot Analytics (WSA) is a software solution that helps welding engineers in taking faster, more accurate decisions, and increase weld quality while avoiding inefficiencies and reducing wastes.

Many are the challenges affecting welding operations: controllers provide their data only at a cell level, which makes it difficult to cross-correlate data from other cells in order, for example, to detect the quality trend of a part as it moves along the line. Destructive tests represent the only reliable method to identify the ground truth on whether a spot was welded according to quality specifications or not. Unfortunately this process is highly inefficient and there is no tool that can help welding engineers in deciding which part has to be sent for testing.

Until now. At its core, Weld Spot Analytics software provides easy access to all welding controllers on the shop floor. No more wasting time sifting through complicated interfaces, all the most useful information can be reached with just a couple of clicks away. Finally, some of the latest machine learning algorithms will analyze the data and help welding engineers in quickly finding their answers.

For more information, please reach out to the WSA team.

WSA BEHIND THE SCENES

Weld Spot Analytics is the combination of 5 main components:

- 1. A cloud deployed architecture specifically designed to represent welding data and capable to support machine learning tasks

- 2. A smart edge module that provides secure connection to the welding controllers on the shop floor and also machine learning inference close to the source of data

- 3. A beautiful browser-based user interface, capable of displaying a variety of data with a great look-and-feel

- 4. A simple but rich user experience, we believe in providing a solution that does not require a user manual

- 5. An artificial intelligence engine that will allow to use the latest and greatest machine learning algorithms to detect anomalies, customizing them to the end user’s specific use cases

Controls and Monitoring Welding Technology

PSQ 6000 - for supreme quality in spot welding

The PSQ 6000 control system is designed to monitor quality performance in high-volume production operations. Intelligent current/voltage control maximizes process reliability and provides online verification of spot weld quality. The BOS 6000 operating interface includes logging and documentation features.

Control and monitoring functions are integrated in the control system. The XQR control card is available as an upgrade for older PSI 6000 series systems.

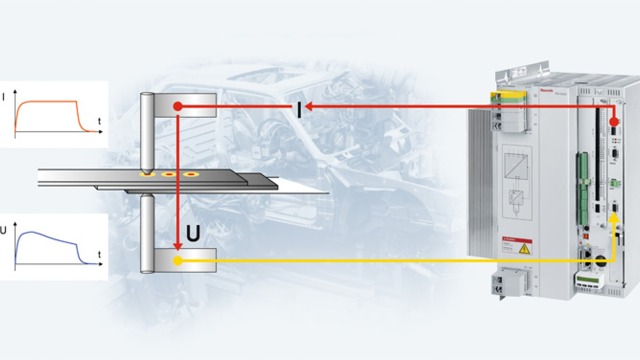

Adaptive current/voltage control for perfect welding quality

The adaptive process control system gives you added flexibility for future requirements in the welding process. By measuring current and voltage, the course of resistance and energy can also be calculated, controlled and accurately evaluated during welding. The adaptive control algorithm ensures consistent quality and reduces spatter in demanding welding applications. Expensive rework is therefore considerably reduced.

Process monitoring

Tolerance limits can be set and monitored for a number of basic process parameters: current, phase angle, electrode voltage, resistance, current time cycle, power and energy. Two consolidated variables, which summarize the basic variables, are provided to simplify system handling:

- PSF - the process stability factor indicates the stability of the welding process

- UIP - the quality factor provides an indication of actual product quality

Q-Stop logic

Patented Q-Stop logic is a very useful extension of monitoring functionality. It enables users to analyze and optimize system productivity by defining how the system reacts to repetitive faults in a program or on a particular part.

Process overview

To provide the big picture, the status of all attached welding controllers is displayed on a bar graph.

Operating and diagnostics software/devices

BOS 6000 – Operation and observation to perfection

The windows-based BOS 6000 user interface with built-in SQL database function makes it very easy to operate the system and monitor performance. You can operate both the welding controller and the process module on a standardized BOS 6000 user interface. The BOS 6000 also provides connectivity to higher-level data processing systems.

Minimum requirements:

- 2 GHz Intel Pentium M processor or comparable

- 1 GB RAM or more

- Windows 7 (32-bit, 64-bit)

- Windows XP operating system with service pack 3 at minimum

- Microsoft Internet Explorer 5.0 (or higher)

- RS232/V24 connection or fieldbus

IndraControl VCH 05 – flexible manual operator panel for mobile use

With the web-based manual operator panel IndraControl VCH 05 many controls can be used arbitrarily mobile. No special knowledge is necessary for the simple operation. The latest processor and communication interfaces provide fast access to welding parameter and diagnostics.

IndraControl VPP 40 – compact PC system for industrial applications

The robust VPP 40 industrial PC is the complete solution for control, operation and visualization. It is specifically designed for use as a cellular or wired PC and can be integrated inexpensively in control cabinets. Depending on the operating requirements this PC can be supplied with a touch screen or keyboard.

PS 6000 - flexibility with I/O

Open, manufacturer-independent bus systems will become established for I/O and communications applications as part of control and automation technology. The unique feature of the PS 6000 welding controller is its I/O flexibility. PS 6000 modules are flexible when it comes to designing the input and output assemblies. They can be equipped with a parallel I/O box or with standardized serial sensor actuator bus interfaces such as PROFIBUS, INTERBUS, and DEVICE NET. Simply connecting the respective assembly is all that is required to configure the PS 6000 control and power section modules.

This translates to a wide variety of applications along with a cost-effective way to realize future extensions or modernization measures.

Discrete I/O

24 V inputs (21x.):

- 24 V DC input signal "1": 24 V DC, +/- 15 %

- Input signal "0": -1 V ... 2 V or open

- All inputs have an indicator light

24 V outputs (13x):

24 V DC, load capacity as per the specifications in the performance specifications sheet. Interference must be suppressed when controlling inductive loads. All outputs have an indicator light.

Device Net

Serial I/O module via Device Net

Discrete 24 V input/output box with 8 inputs and outputs and a serial 32-bit input/output box via DeviceNet.

Profibus DP

Serial I/O module with input/output box via Comnet DP as per C0 profile

Discrete 24 V input/output box with 16 free inputs and 16 free outputs. Serial 32-bit input/output box via Profibus DP C0 profile.

V24

I/O module with RS 232 interface for special robot connections

Serial V 24 interface

Fiber-optic interface

Serial Interbus S I/O module with air-water cooling

Remote bus with discrete 24 V input/output box. Eight (8) free input and outputs and a 32-bit serial input/output box via Interbus S as per C0 profile.

Open for intelligent communication

Ethernet - the future of industrial communication

The increasing number of control components, actuators, and sensors in industrial automation gives rise to more complex control networks. Industrial communication in the future will be characterized by highly cost-effective networking of these automation components with the Ethernet standard, adapted to meet the requirements of industrial automation.

Fast Ethernet technology offers many benefits:

- Recognized, forward-looking technology

- 10 to 100 times higher data throughput rates than with fieldbuses

- No expensive or proprietary hardware required

- Standard components such as double-shielded CATSe copper cable, connectors, and controllers in high quantities (e.g. FPGAs)

- Broad-reaching IT concepts with an integrated transmission medium from office to field level

- Flexible and compatible automation systems thanks to international standardization

- Possibility of global networking for diagnostics and maintenance purposes

Ethernet IP 1-port

Complete EtherNet/IP adapter (slave) level 2 I/O server, Max. of 256 bytes of input and 256 bytes of output data (depending on the welding control system)

Automatic baud rate detection, 10 or 100 Mbit/s in semi/full-duplex mode, Integrated potential separation

Ethernet/IP connection via RJ45 standard socket, Embedded Web server possible

Ethernet IP 2-port

Ethernet/IP connection via 2 RJ45 standard sockets, Device Level Ring (DLR) and linear network topology supported

Complete EtherNet/IP adapter (slave) level 2 I/O server, Integrated potential separation

Automatic baud rate detection, 10 or 100 Mbit/s in semi-full duplex mode, Embedded Web server possible, "unconnected CIP routing" supported

Profinet

The embedded Profinet module is optimized for use in intelligent automation devices such as drives, control terminals, industrial scales, and control systems. It is typically seen in applications that require large quantities of data to be transferred at high throughput rates together with isosynchronous cycling.

Profinet IO (1-Port):

Parallel 2 KB dual-port Ram interface, Profinet baud rate: 100 Mbit/s, Profinet real-time functions and IT functions can be simultaneously used

Max. of 512 bytes of cyclical Profinet input and output data (depending on the type of welding controller), Dynamic Web server

Profinet IRT (2-Port):

Intelligent communications module with Profinet IRT functions, Integrated 2-port real-time switch, Profinet IO device functions i.a.w. conformance class C

220 bytes of cyclical input and output data each (depending on the type of welding controller), Based on Siemens ERTEC-200 processor and Siemens IRT software stack

Profinet IRT interface with optical fiber cable connection:

Intelligent communications module with Profinet IRT functions, Profinet IO device i.a.w. conformance class C, Integrated 2-port real-time switch

Profinet connection via SC-RJ optical fiber cable connections, 220 bytes of cyclical input and output data each (depending on the type of welding controller)

Supports enhanced optical performance diagnostics i.a.w. the AIDA requirement specification, Based on Siemens ERTEC-200 processor and Siemens IRT software stack

Support

Get in Contact with us!