Author: Andreas Hassold and Matteo Dariol | October 15, 2020

The productivity gains promised by Industry 4.0 are, without a doubt, desired objectives for many manufacturers. As more and more organizations start their journey into this smart/digital manufacturing world, it's common for them to encounter a scenario called "PoC limbo". In this article we will describe how to avoid this type of roadblock.

The productivity gains promised by Industry 4.0 are, without a doubt, desired objectives for many manufacturers. As more and more organizations start their journey into this smart/digital manufacturing world, it's common for them to encounter a scenario called "PoC limbo". In this article we will describe how to avoid this type of roadblock.

Let's start with a definition: PoC limbo, sometimes referred to as PoC purgatory, is the scenario in which several Proof of Concept projects are initiated but, for various reasons, never completed. These projects "fluctuate" in an incomplete status mainly because of lack of communication among the various stakeholders in the organization, who are unable to judge the effectiveness of a solution based on a set of pre-defined metrics. This specific outcome is particularly dangerous when you consider the fact that a project "stuck in limbo", because it is not technically finished, will not be considered as failed, and therefore those responsible will be unable to determine the causes of failure. The only result in this situation is a continuous loss of time and resources that is hard to stop.

One of the most successful principles in avoiding PoC limbos, is to invert your perspective on your opportunities: rather than using a "technology forward" approach, we've found that a "bottom-line value backward" strategy is better suited to help all parties prioritize and focus on the pain points that lead to a clear ROI faster.

Defining a Roadmap

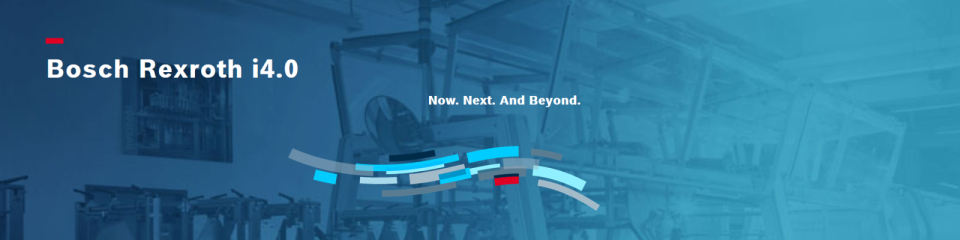

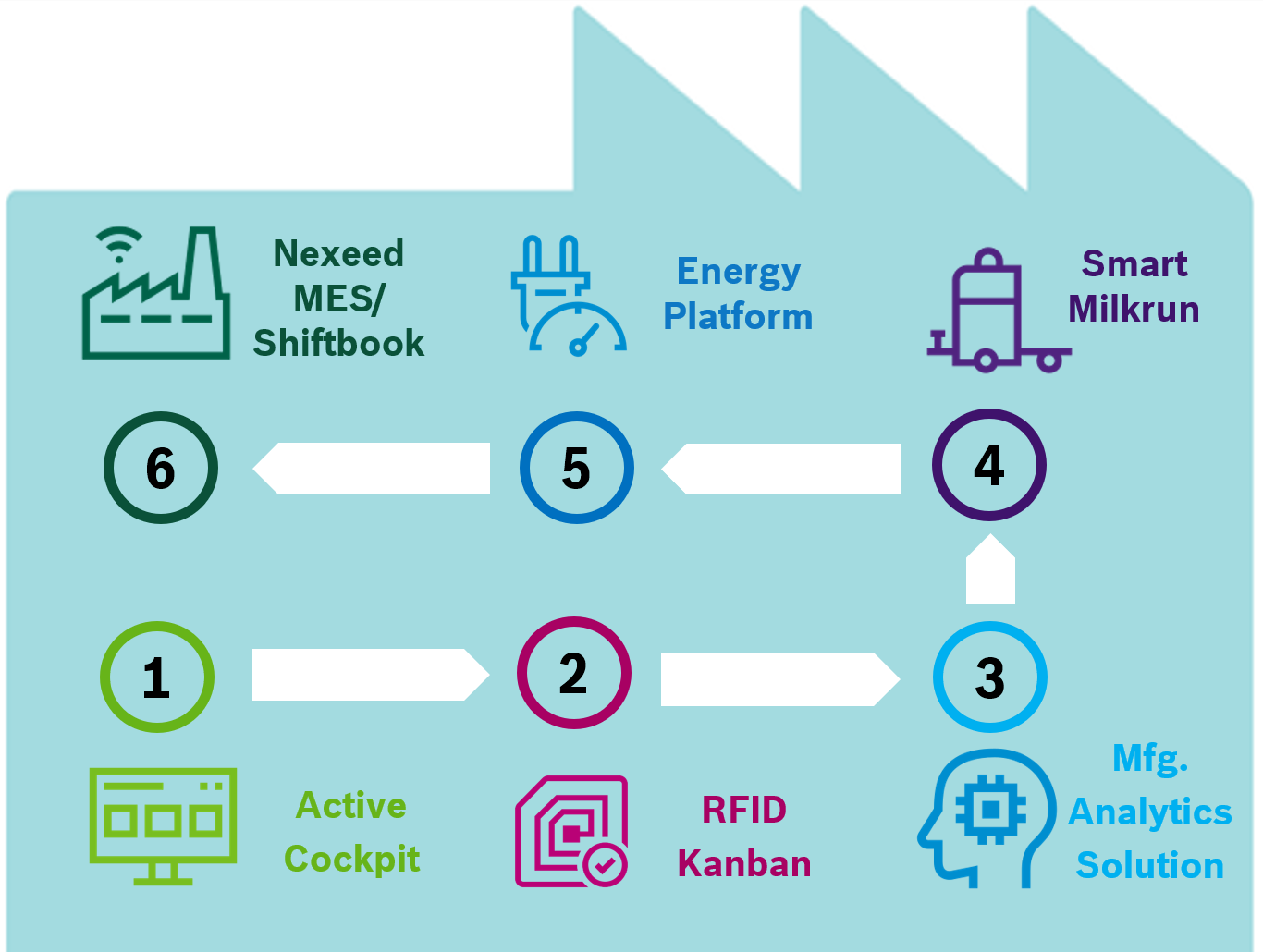

In most cases a significant shortcoming is an insufficient roadmap that is predominantly focused on IT or technology items around IIoTor Industry 4.0. As described in a previous post a holistic approach that connects technology and lean manufacturing is paramount.Hence, a robust roadmap needs to focus and include details of both the IT and OT topics.

In most cases a significant shortcoming is an insufficient roadmap that is predominantly focused on IT or technology items around IIoTor Industry 4.0. As described in a previous post a holistic approach that connects technology and lean manufacturing is paramount.Hence, a robust roadmap needs to focus and include details of both the IT and OT topics.

So, how can you accomplish that? There are several methods to choose from, and we've found that one of the most successful is a Kickstarter Workshop.

Within this setting, we can accomplish a variety of different goals:

Education on i4.0 integration with lean manufacturing

Establishing a clear vision and mission

Generating competencies and organizational structure required for a seamless and successful transformation

Change Management specifically to digital transformation

A clear tie to daily operational pain points

In order to derive a list and prioritization of daily and operational pain points that need to be addressed, one can utilize tools like Rolling Top 5(RT5) out of the Shainin approach, paired with a holistic System-CIP (Continuous Improvement Cycle) to capture not only the"heavy hitters"but to also expose smaller issues of similar nature.

Bringing the pain points in line with your newly created Vision, and building on a solid lean foundation while applying a change management initiative, you'll be able to focus on projects that have the backing of your organization and solve problems with a much higher success rate.

How to Measure Success

So now that your organization has defined a clear path forward for Industry 4.0, let's assume that a set of solutions are prioritized, and their implementation is planned.All the stakeholders involved in the project must sit down at the same table and define a set of success metrics, which can vary from group to group: management might have a set of KPIs defining success that are totally different from the manufacturing team's metrics.

Every new project implementation must be evaluated at certain determinate stages or milestones, during which the relevant stakeholders can measure how well the solution is performing. This is not only crucial from a performance standpoint, but will allow you to modify your approach as needed--changing direction or even killing a project that's no longer delivering on its promises.

A proper IIoT solution evaluation metric is essential to avoid getting stuck in PoC limbo; this approach is valid in the case of a custom solution developed in-house, as well as in a system integration scenario.

Change Management

There are different methods and tools available to address change management. The important thing is that you have a plan. A simple ADKAR Stakeholder Analysis, for example, will allow you to apply methods like DISC profiles or Myers-Briggs to understand what support you can get and what roadblocks you will potentially encounter.

Start small, give users the ability to get familiar with the newly generated data and information. Tie this back to the user stories you created during your roadmap development process. Incorporate the new approach in your daily shopfloor management cycles, and have the entire team contribute and participate. Gamification can be a good way to drive acceptance of new data and information.

Once the data and information gener`ated by your new IoT solution is successfully embedded in your daily operation and described via standards, you can roll out the application to other areas, without fear of getting stuck in PoC Limbo.

Scaling and Operations

So that's it. You've successfully designed and implemented a novel Industry 4.0 solution that makes management happy, brings a noticeable efficiency improvement with contained development costs and has a good UX, helping operators include it effortlessly in their daily routine. Now it's time to scale it. Your solution has been proven to work with a reduced number of machines but scaling it to the whole plant will bring a whole new set of constraints. Payloads and data flows must be optimized for "production", edge devices and servers must be resized to accommodate for the new computational power required.

So that's it. You've successfully designed and implemented a novel Industry 4.0 solution that makes management happy, brings a noticeable efficiency improvement with contained development costs and has a good UX, helping operators include it effortlessly in their daily routine. Now it's time to scale it. Your solution has been proven to work with a reduced number of machines but scaling it to the whole plant will bring a whole new set of constraints. Payloads and data flows must be optimized for "production", edge devices and servers must be resized to accommodate for the new computational power required.

This is the phase where proper partner management activities must be setup and kept alive, especially if some of those new solutions were implemented using outsourced engineering service companies and system integrators.IT experts know this well: a house is built to stay the same, software is built to be changed.Maintaining software requires constant attention to every component. For example, a new software release might break dependencies to certain libraries , or exposed security flaws might put your whole operation at risk if not patched promptly.

Finally, in order to guarantee long term success of any Industry 4.0 activity, an organization must be able to attract and retain talent. A committed and knowledgable team is essential to guarantee an effective IT & OT bridging and build the cross-functional competencies required in our complex world.

< BACK TO ARTICLES < BACK TO i.4.0 HOME