We are a competent partner for hydraulic casting, cast products for general mechanical engineering and cast components for glass mould production. Extensive investments have enabled us to achieve our strategic objective of extending our long term lead over our competitors in terms of technology and innovation, particularly in the hydraulic casting segment.

Moulding and Casting Technologies

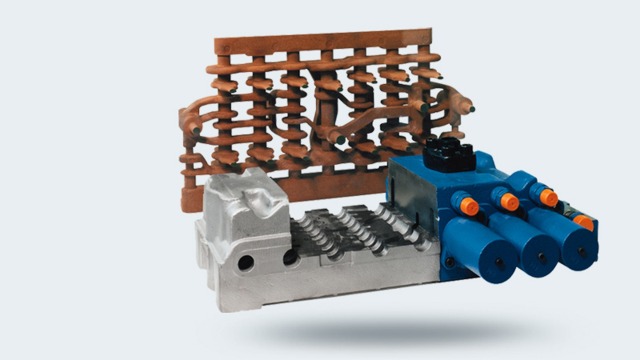

Together with our customers, we find solutions for almost every challenge by combining a unique variety of the latest technologies with our expertise. Quickly available prototypes play an important role in the development of new components. Development time and thus development costs are reduced, thereby providing competitive advantages. We cover the entire process chain in-house and provide you with a full service from a single source, thanks to facilities such as the two 3D printers we have owned since 2012. The production time for a usable casting product can be reduced from 12-14 weeks to 2-4 weeks. We also use this technology for small series parts and the production of prototypes. The advantages of this process are particularly noticeable in highly complex geometries. Core assembly sites and drafts can be omitted, undercuts no longer pose a problem, and geometry changes can be implemented very quickly.