The first fully electronically controlled Menzi Muck M4x walking excavator series enables highly dynamic, precise work functions using Bosch Rexroth hardware and software solutions. It increases the mobile machinery’s productivity and efficiency. The manufacturer is also developing digital value-added services for its customers, for example, fleet management, condition monitoring and geolocalization based on the Rexroth BODAS Connect IoT and telematics solution.

The function and aesthetics of the Menzi Muck M4x designed by Bicego Design received the Red Dot Award in 2024. The off-highway vehicle’s high power, precision, and efficiency is thanks to the cutting-edge hardware and software solutions from Bosch Rexroth. (Image: Menzi Muck AG)

The Menzi Muck walking excavators impress due to their versatility and innovative technology. Thanks to the parallel adjustable wheels and optional hill supports, they even cope with steep slopes, bodies of water and deep ditches. The patented telescopic arm gives the excavator an even larger working range, which can be used to full advantage with many attachments. Whether it’s in the construction industry, forestry, garden and landscape maintenance or for drilling and municipal works: the Menzi Muck is a real all-rounder.

This functionality and the fine tuning between the travel drive, boom, and attachment parts require extensive expertise from the manufacturer and demand the highest requirements from the control system. With its new M4x model series, Menzi Muck has therefore realized a concept with fully electronic machine control, electro-hydraulic technology, and integrated IoT and telematics solution for the first time.

“The fully electronic machine control makes the M4x series walking excavator even more powerful and energy efficient,” explains Christian Deiss, technology manager at Menzi Muck AG. “As the electronic hydraulics can cover more operating situations than previously, the power, precision, and energy requirements can be individually adjusted. This not only allows for faster excavation times but also even more precise positioning of boreholes and the individual adjustment of the response behavior to the operating personnel’s preferences.”

The long-standing technology partner Bosch Rexroth provides the technical basis for this. The biggest innovation in the new walking excavator series is the electro-hydraulic control of the working pump, which Menzi Muck has implemented for the open hydraulic circuit using the Rexroth eOC system (electronic open circuit) and electro-hydraulic controllable axial piston pumps. “The high variance of the hydromechanical control functions including interfaces is transmitted to the software with the help of the eOC BODAS pump control,” explains Rexroth project manager Markus Donner. “As a result, Menzi Muck can adapt the control mode to the situation and variably adjust the pump dynamics during ongoing operation.”

The drive motor and axial piston pumps can communicate directly with each other through the control software to continuously and dynamically adjust the hydraulic power to the available drive torque. The pump software can also compensate for faults in the machine’s load cycles, allowing for highly dynamic and very precise work functions as well as higher overall productivity for mobile machinery.

As a working pump for the eOC system, the new M4x uses the compact A11VO high-pressure adjustment unit for the open circuit. The associated eOC software includes a function to control the pressure flow rate so that high power can be provided for the attachments with a variable maximum pressure of up to 320 bar. The associated flow sharing control block was realized on the basis of the Bosch Rexroth flexible RS valve platform, which is also optimized for electro-hydraulic control. Thanks to the sandwich plate design, different functions can be integrated to save space, for example a steering priority.

Walking excavator in use: the Menzi Muck M4x copes with steep slopes and challenging terrain using innovative technology. The tilt edge can be optimized for maximum lifting and tearing forces using the adjustable wheel and claw supports. (Image: Menzi Muck AG)

The compact A4VG axial piston unit with high power density is used for the electro-hydraulic travel drive in a closed circuit. A second A11VO axial piston unit provides power in an independent hydraulic circuit for the “Powerline”, which powers the attachments that Menzi Muck supplies from a single source. In addition to shovels, grabs, and the quick-change system, these also include demolition and mining systems, mulchers, harvesters and stump grinders.

Bosch Rexroth has also developed load limit control software to be able to control or limit the attachments independently of the pressure level. “It must be guaranteed that the machine can be controlled at all times,” emphasizes Deiss, giving the example of mulching undergrowth on the ground while travelling. “With the eOC system and software from Bosch Rexroth, the required amount of oil is calculated exactly in advance and provided efficiently.”

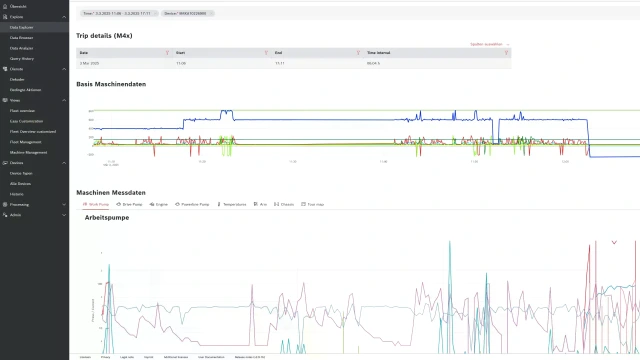

Menzi Muck customer service dashboard (Image source: Menzi Muck AG)

The Rexroth site in Switzerland also took over the whole reprogramming of the fully electronic excavator control, where the current RC/40 controller series controls both the hydraulics and mobile electronics. The software engineering included both the transfer of the previous work routines to the new infrastructure and working on the travel drive software: “We would not have been able to cope with these challenges on our own,” reports Deiss. “At the same time, this provided the foundation for the electronification of other models, which we want to develop further on the basis of the Bosch Rexroth BODAS ecosystem, which is open to different technologies.”

Menzi Muck receives more support from Bosch Rexroth in the area of telematics and IoT with the BODAS Connect complete solution. Besides the robust RCU (Rexroth Connectivity Unit) telematics unit, its core components also include the Bosch IoT Suite, which features over-the air services such as software and firmware updates, parameter readouts, and error diagnostics, and is well-established in high volume production. “Remote maintenance capabilities are a prerequisite for us for further growth and success in remote areas of use with poor service coverage, for example in Asia or South America,” says Deiss. “With the help of OTA services, we can provide remote maintenance anywhere and prepare our service partners’ on-site jobs more efficiently.”

In addition, Menzi is developing value-added services for its customers with the help of the BODAS Connect telematics and IoT solution’s data management module, for example fleet management, condition monitoring, geolocation or hourly-based billing. The telematics complete solution includes many prepared standard functions, relevant interfaces for industry sectors, and role-based user management to implement corresponding offers quickly and easily. The associated user interfaces with analyses, diagrams, graphics, and widgets can be created quickly and easily using templates.

RCU4-3Q/20: BODAS Connect telematics device for connecting working machines to the cloud. (Image source: Bosch Rexroth AG)

In the future, Menzi Muck would also like to use the comprehensive telematics solution to collect detailed machinery data such as the power range or more pump information. This will then be incorporated into a digital twin and will help evaluate new projects. New business models are also feasible, for example a rental service for the Powerline pump for use with attachment parts.

Despite a few learning curves, the technical manager sums up this complex engineering project extremely positively: “Without the assistance of Bosch Rexroth, it would not have been possible to electronically replicate a system that has been optimized over 30 years in just three years and to be able to offer our customers an even more efficient machine with cutting-edge technology,” concludes Deiss. “The first 40 M4x models in the field clearly demonstrate the improved controllability and reliability of the new components.” According to Deiss, the customers seem to appreciate the new advantages. “Quality and availability are what count at the end of the day. At Menzi Muck we share this value with our partner Bosch Rexroth.”

Author: Markus Donner

Position: Sales Europe Middle, product area

Mobile Applications, Switzerland

Phone: +41 (55)4646-273

Cell: +41 (79)7575049

Markus Donner

Already connected on LinkedIn?

Markus Donner

Bosch Rexroth AG