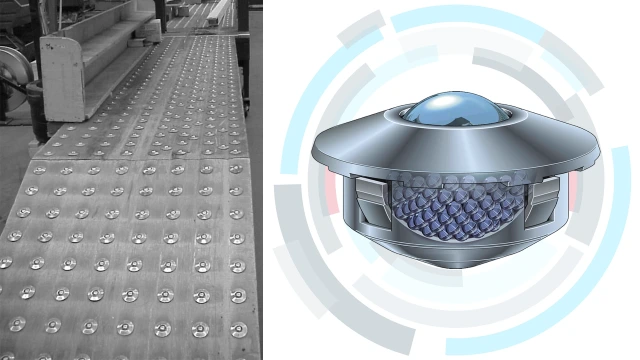

Ball transfer units are true all-rounders. They ensure a reliable flow of materials in a wide variety of scenarios. With these five selection criteria, machine and system manufacturers can achieve optimum performance and service life with minimum maintenance costs.

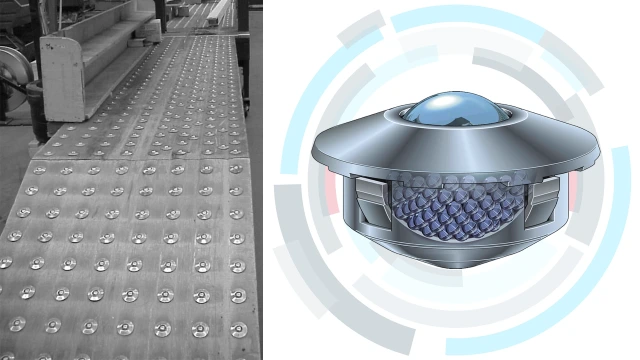

Lightweight or heavy duty, size 8 or 120, with a spring element or a plastic ball – the range of applications for ball transfer units in mechanical and plant engineering is diverse. If this can be covered by a supplier with a comprehensive, low-maintenance portfolio, you can save time and money. Bosch Rexroth offers the highest load capacities for every application and the best performance in every installation position.