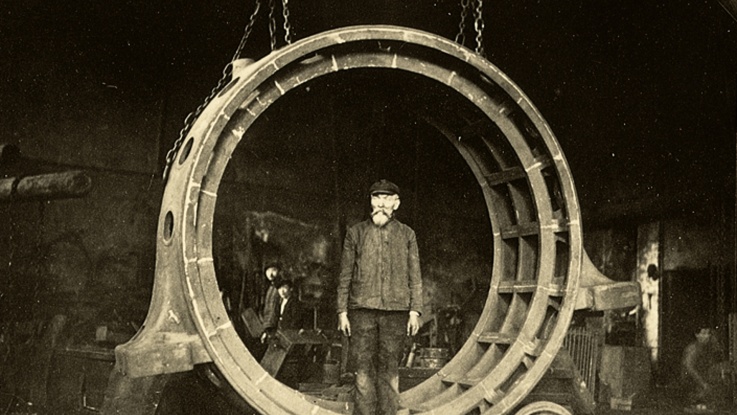

The origin of Bosch Rexroth's long history is influenced by constant movement. It all started with a water-powered hammer mill, followed by an iron foundry in Lohr am Main. Bosch Rexroth’s unique industry expertise has become synonymous with tailored solutions.

Bosch Rexroth - Our History

1795 – 1964

Move from iron foundry to hydraulic solutions

From forging iron out of ore to a foundry for cast iron, Rexroth entered the hydraulics market in the 1950s and laid the foundation to become a global market leader.

1965 – 1995

Move from hydraulics to multi-technology provider

The company expands its portfolio with electrical drives and controls, axial piston pumps and motors, linear and assembly technologies and develops into a full provider of industrial and mobile hydraulics.

1996 – 2000

Move to provide integrated multi-technology solutions

Rexroth develops multi-technological solutions to overcome the limits of single technologies, unlocking the progress in semi-conductors and software for all technologies to increase productivity and flexibility.

2001 – 2016

Move to one brand for software driven and interconnectible Drive & Control solutions

The merger of Mannesmann Rexroth with Bosch Automationstechnik establishes a global leader for Drive & Control solutions. They reach new levels of seamless integration of all relevant technologies for improved energy efficiency and safety.

2017 – today

Move into the future of digital transformation

Bosch Rexroth drives the digital transformation of the Factory of the Future, exceeds the limits with Connected Hydraulics and sets the stage for Transforming Mobile Machines. All products and solutions contribute to a more sustainable development of machines, manufacturing and daily life.